Motor cooling casing, motor and vehicle

A technology for motor cooling and casing, applied in the fields of vehicles, motor cooling casings, and motors, can solve the problems of low heat exchange efficiency, insufficient turbulent flow, insufficient heat exchange contact between coolant and casing, etc. The effect of thermal contact area, improving heat exchange efficiency and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

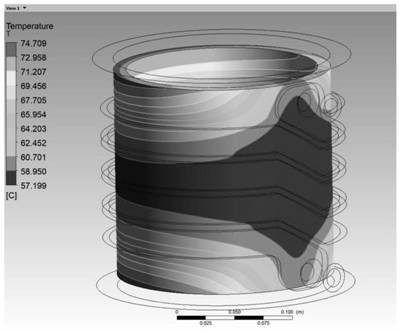

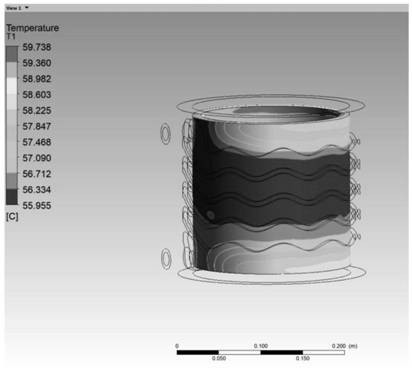

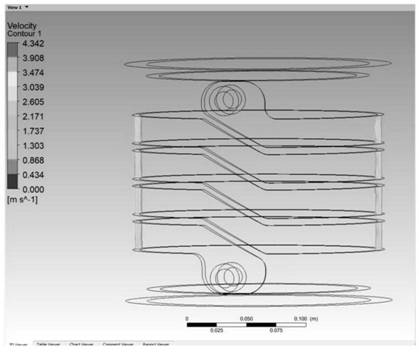

[0031] see in conjunction Figure 1 to Figure 9 As shown, according to the embodiment of the present invention, a motor cooling casing is provided, including a casing body 1, and a cooling flow channel 4 is provided in the casing body 1, and the cooling flow path 4 is formed along the casing body. 1 is formed at intervals around the runner ribs arranged at intervals in the axial direction, and the runner ribs include a plurality of annular rib segments 21 extending along the circumference of the casing body 1 and can connect two adjacent annular rib segments 21, the connecting rib section 22, and the circular rib section 21 is sinusoidal after being deployed along the circumferential direction of the casing body 1, and it can be understood that the runner ribs are in the casing body 1 A substantially helical structure is formed in the axial direction, and the cooling fluid inlet 31 and the cooling fluid outlet 32 are respectively provided at the first and last ends of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com