Horizontal four-head drilling and tapping machine

A horizontal, drilling and tapping technology, used in metal processing machinery parts, clamping, support and other directions, can solve the problem that iron scraps are easily splashed and stuck on the drilling shaft or tapping shaft or in the gap of the machine tool, the work efficiency is low, and the inconvenience Clean up and other problems, to achieve the effect of compact structure, saving manpower and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

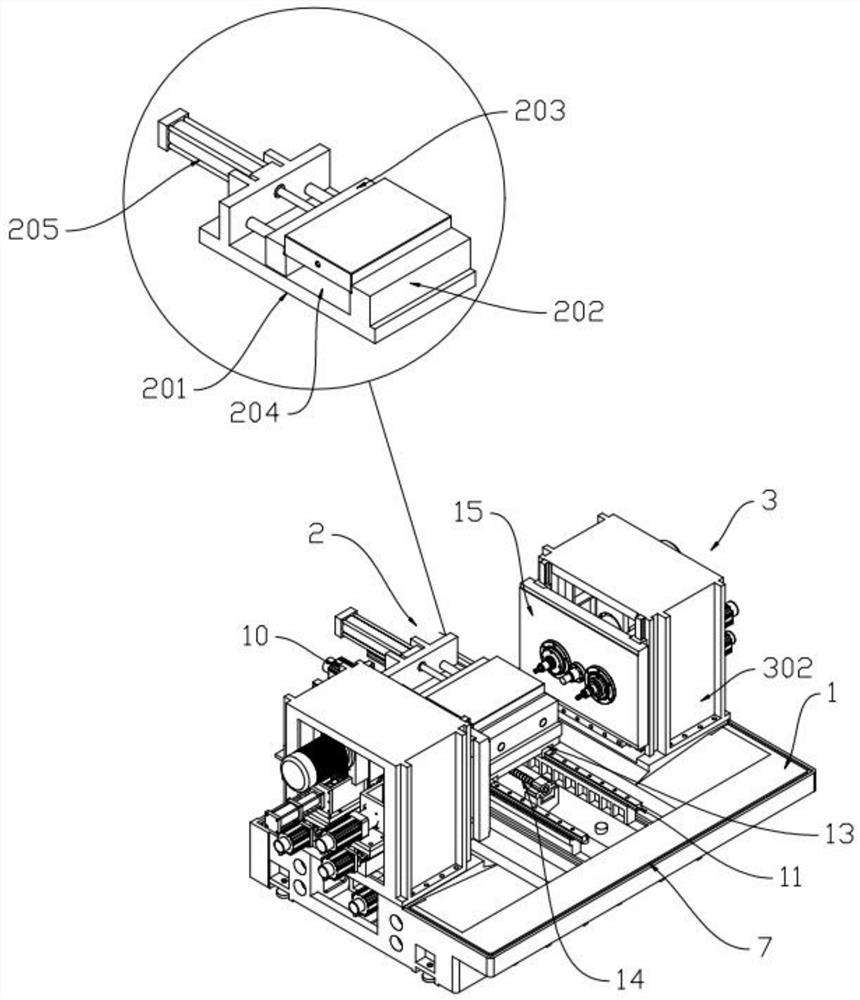

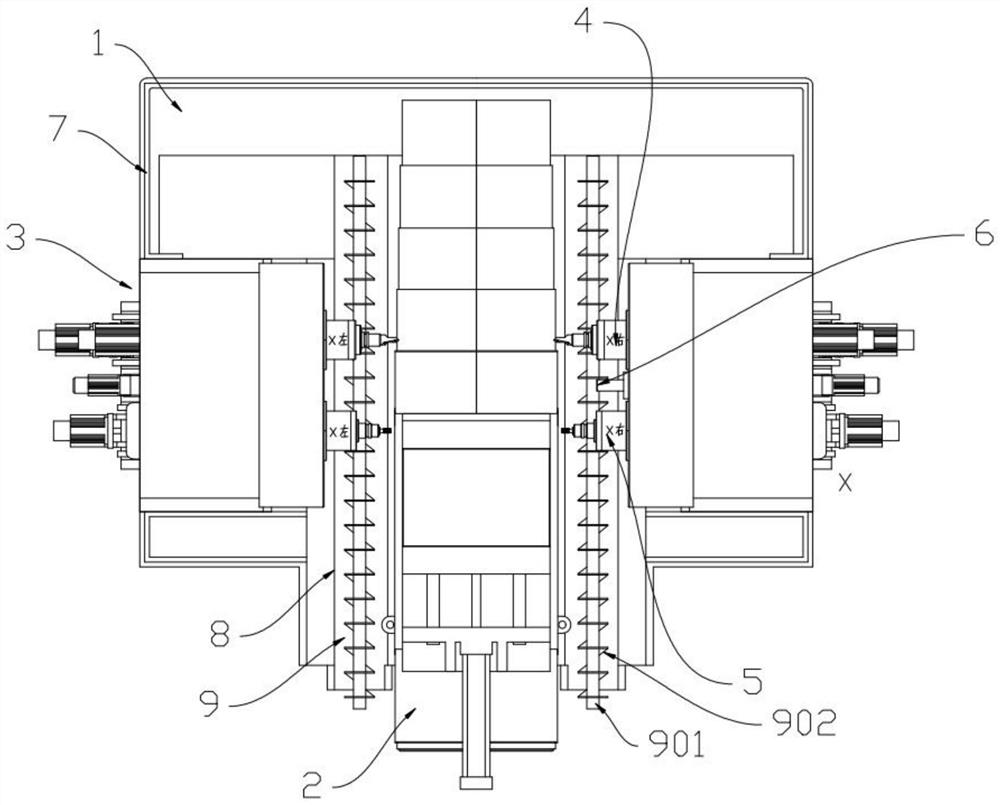

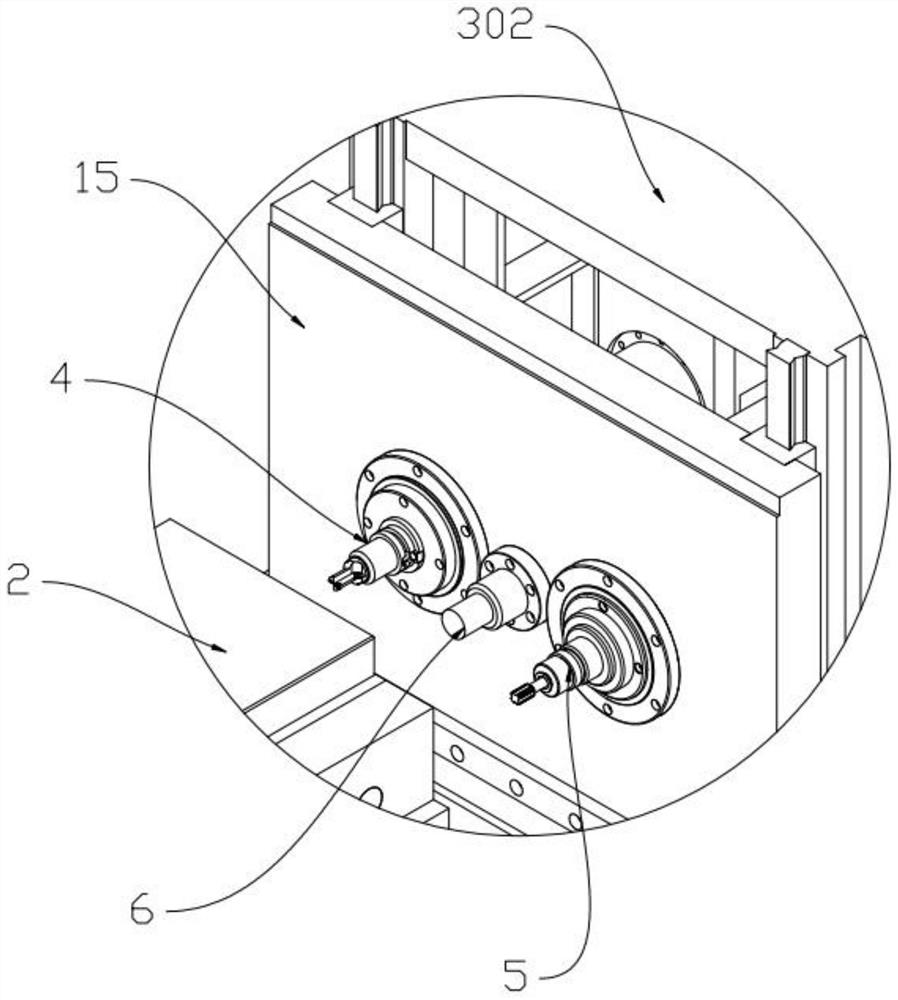

[0034] Working principle of the present invention: a horizontal four-head drilling and tapping machine includes a machine tool 1, the side of the machine tool 1 is provided with a dodge door 17, and the outside is provided with a tool magazine 18, and the machine tool 1 is provided with a template fixing mechanism 2 and The cutter device 3, the template fixing mechanism 2 includes a base 201 slidingly arranged on the machine tool 1, a fixed plate 202 is provided above the base 201, and a moving plate 203 is provided on the other side, the fixed plate 202 and A form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com