Workpiece drilling and tapping system

A technology of workpiece and drilling device, applied in the field of workpiece drilling and tapping system, can solve the problems of inconvenient operation, single drilling, tapping or deburring, and manual operation, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

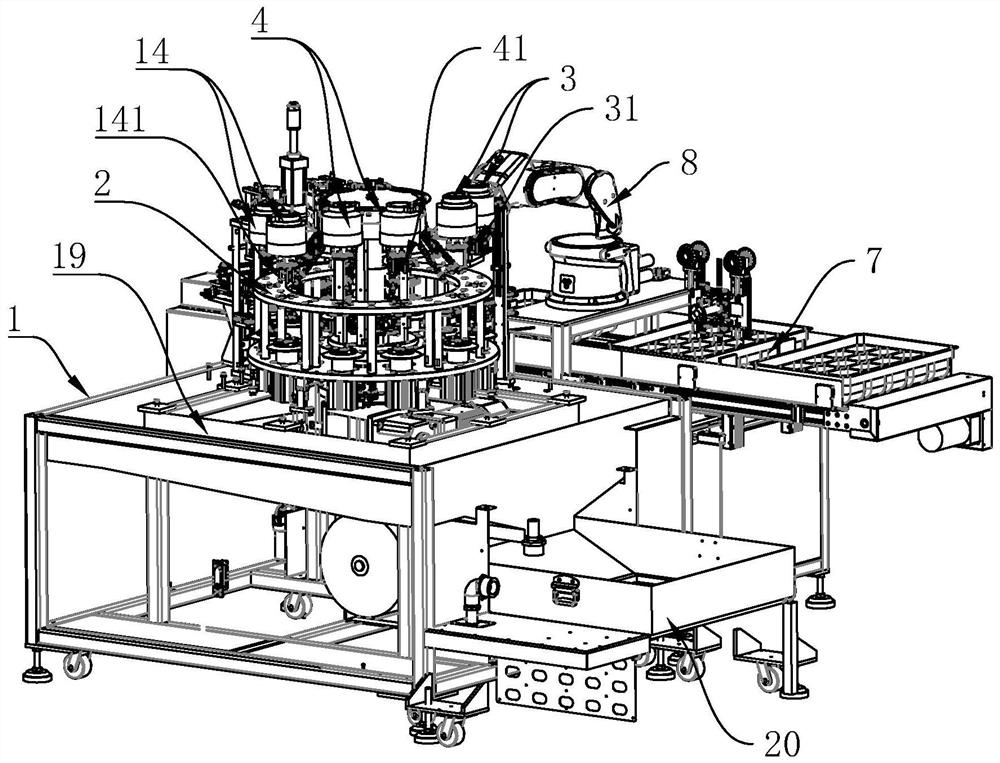

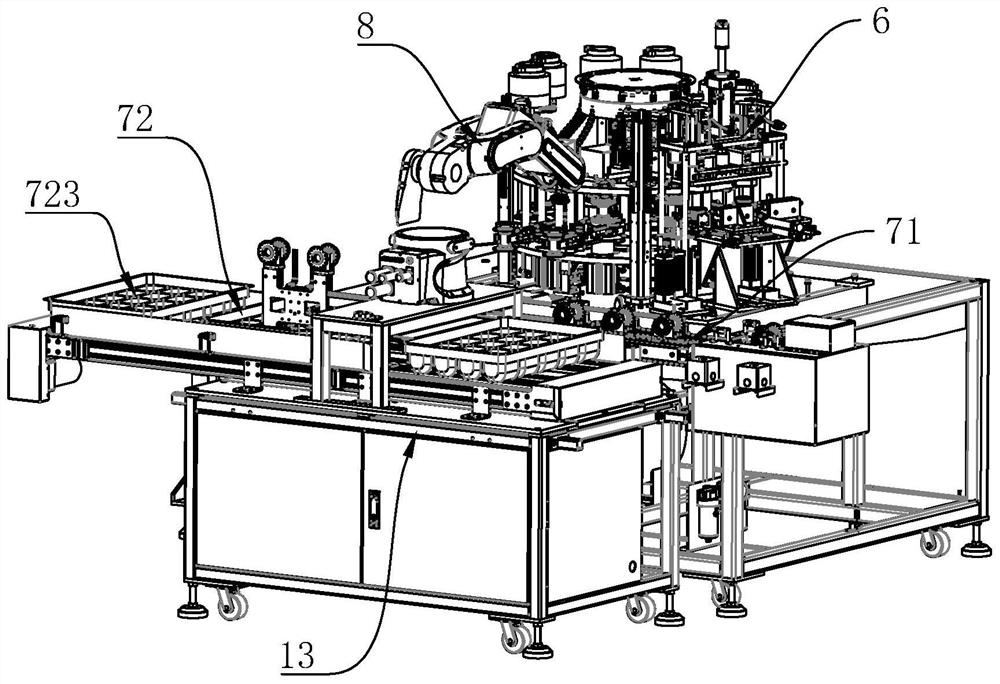

[0036] like figure 1 , figure 2 As shown, a workpiece drilling and tapping system of the present invention is used for automatic loading and unloading, chamfering, drilling, tapping and deburring integrated operations.

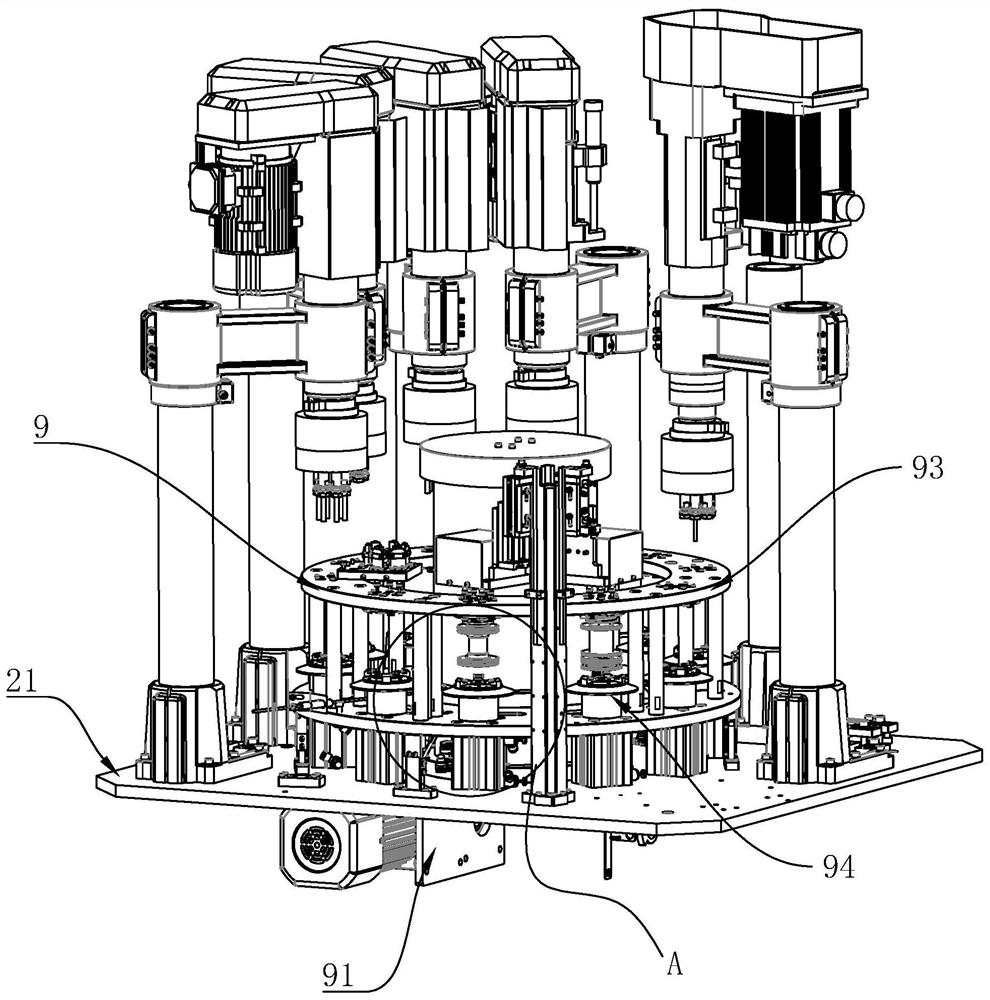

[0037] A workpiece drilling and tapping system, comprising a first workbench 1, a turntable output device 2 is arranged in the center of the first workbench 1, and chamfers are sequentially installed on the first workbench 1 along the turntable output device 2 Device 3 , drilling device 4 , tapping device 14 and deburring device 6 .

[0038] The chamfering device 3, the drilling device 4, and the tapping device 14 are at least set as one group, and in this embodiment, they are set as two groups. The chamfering device 3, the drilling device 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com