Mine lifting equipment with high safety performance

A technology of safety performance and lifting equipment, applied in the direction of lifting equipment safety devices, lifting devices, etc., can solve the problems of low safety and practicability, easy damage of components, uneven tilting, etc., and achieve the effect of improving safety protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

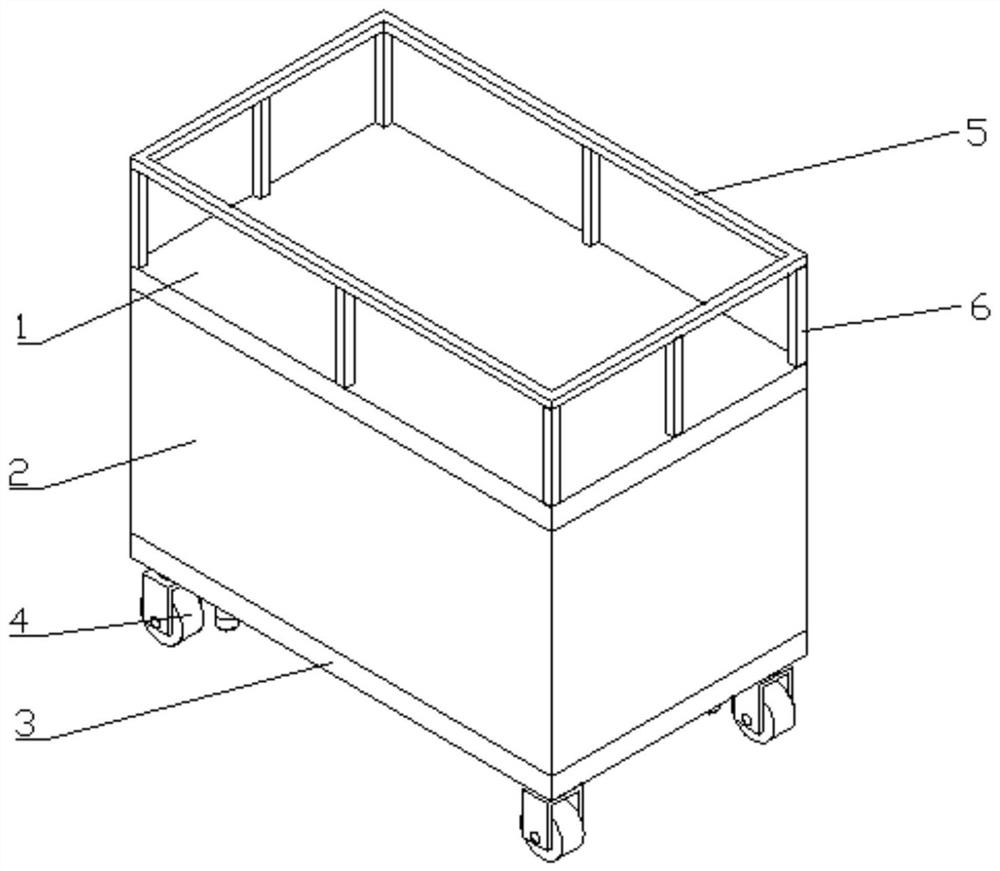

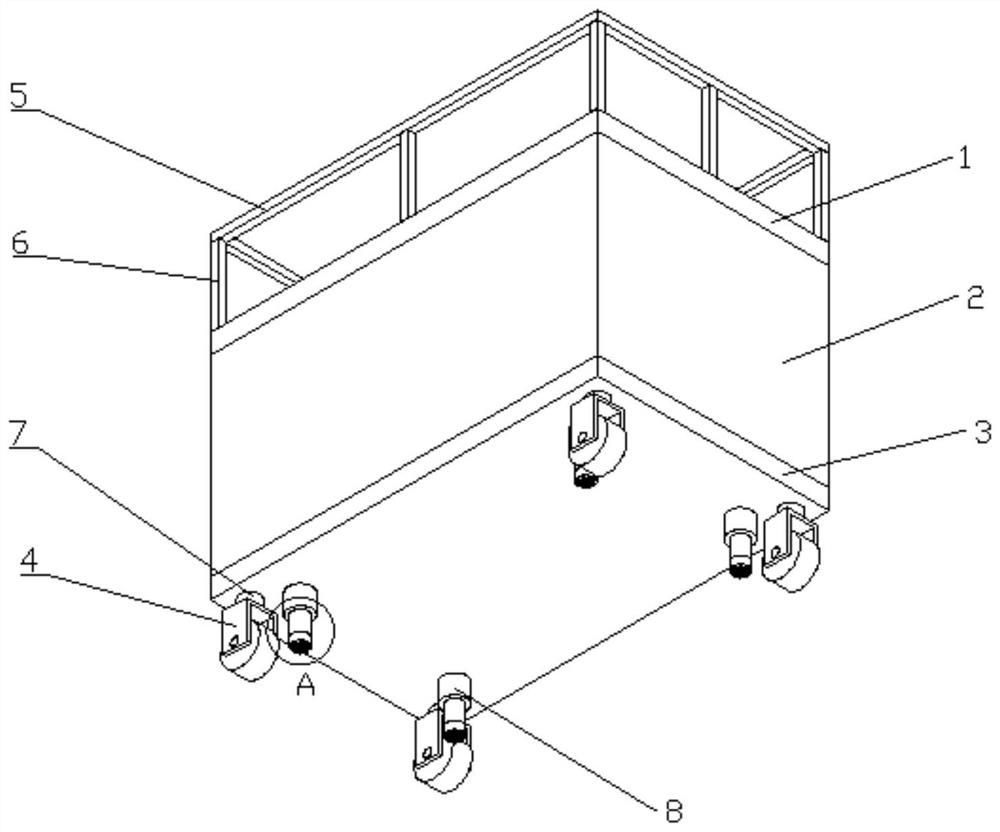

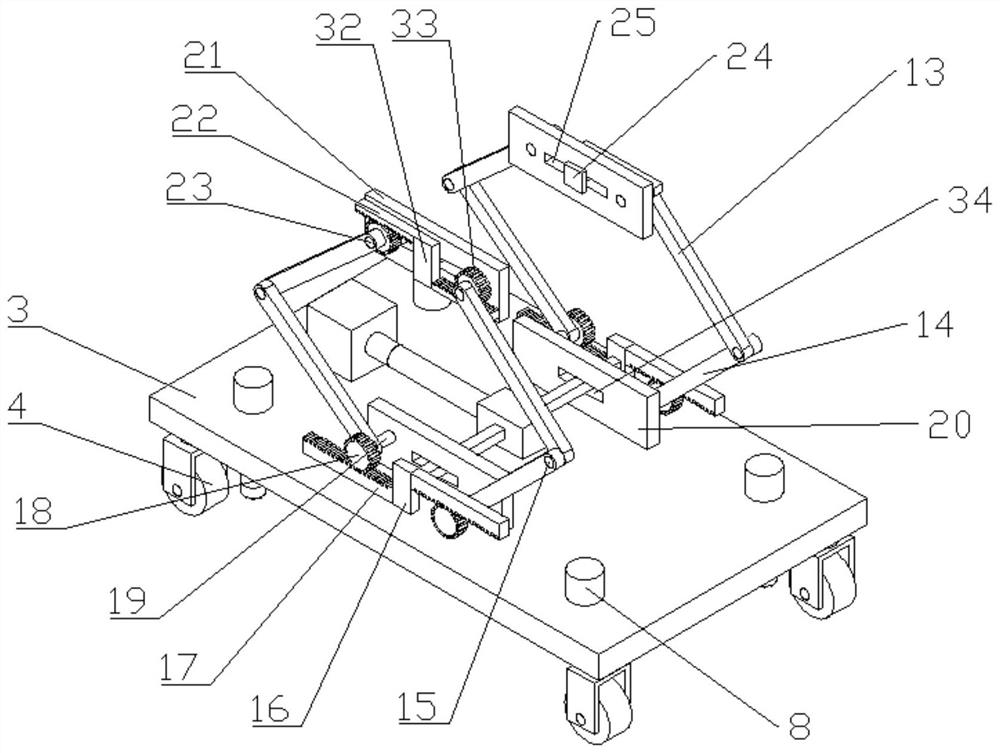

[0032] refer to Figure 1-7 , the present invention provides a mine lifting device with high safety performance, which includes a load-bearing base plate 3, a running part and a fine-tuning part are arranged at the bottom end of the load-bearing base plate 3, a lifting mechanism and a protective shell 2 are arranged at the top end of the load-bearing base plate 3, and the lifting mechanism is located at the protective Inside the shell 2, the top of the lifting mechanism is provided with a jacking platform 1, and the top of the jacking platform 1 is provided with a protective part. ;

[0033] The lifting mechanism includes an action part, the action part is fixedly connected to the top of the bearing base plate 3, and the two sides of the action part are respectively fixedly connected with the first transmission part, the first transmission part is rotatably connected with the bottom end of the lifting part, and the top of the lifting part is rotatably connected with the height...

Embodiment 2

[0056] refer to Figure 8 The difference between this embodiment and Embodiment 1 is that the bottom end of the adjustment table 26 is evenly provided with a plurality of first hinge grooves 36 in the circumferential direction, and the top of the first hinge joint 37 is hinged in the first hinge groove 36, and the first hinge joint The bottom end of 37 is fixedly connected with telescopic support leg 38, and the bottom end of telescopic support leg 38 is fixedly connected with arc-shaped friction block 39. Disc 41, connecting disc 41 is provided with a second hinge groove 42 uniformly in the outer circumferential direction, and one end of a second hinge joint 43 is hinged in the second hinge groove 42, and the other end of the second hinge joint 43 is fixedly connected with one end of a telescopic pole 44. The other end of the strut 44 is hinged with a third joint 45, and the third joint 45 is fixedly connected with the outer wall of the telescopic support leg.

[0057] This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com