Underground ventilation safety comprehensive early warning method based on WebGIS platform

An underground ventilation and platform technology, applied in mine/tunnel ventilation, service based on location information, service based on specific environment, etc., can solve problems such as increased production costs, frequent vehicle transportation, and optimization of ventilation systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

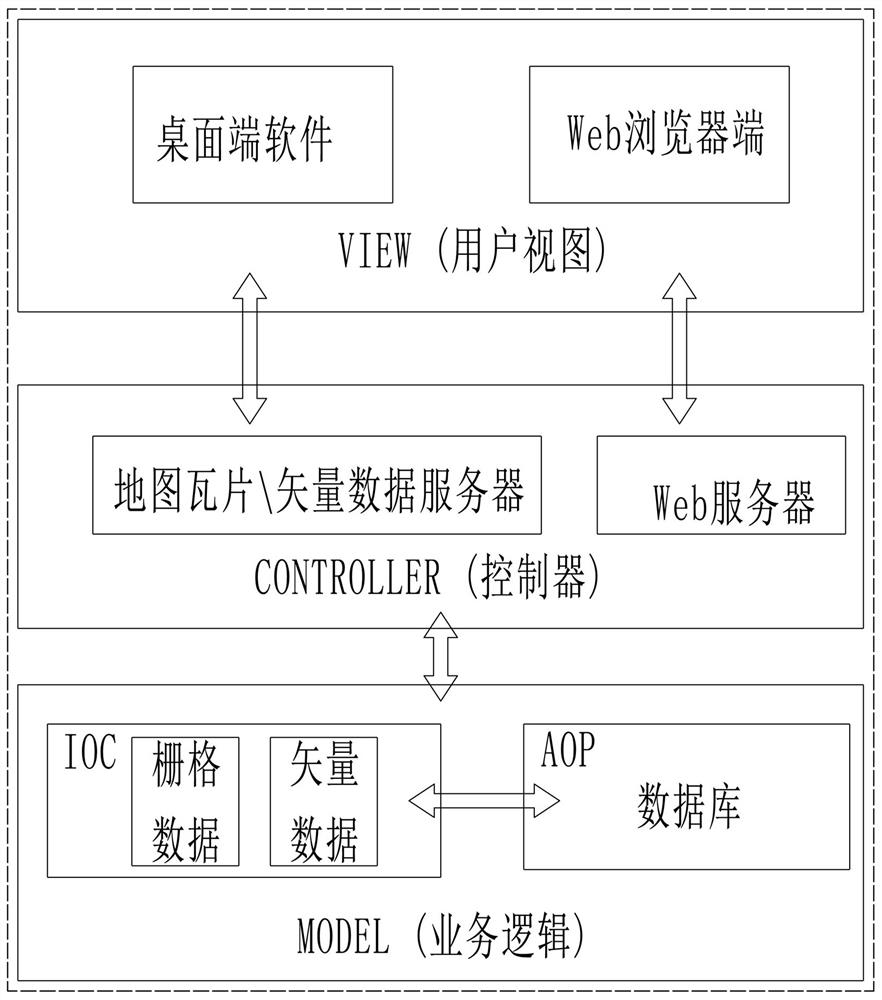

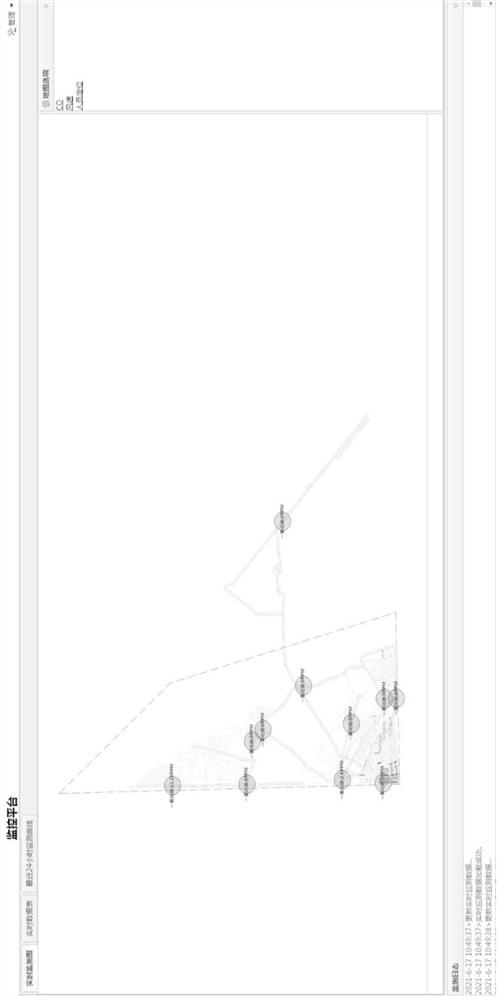

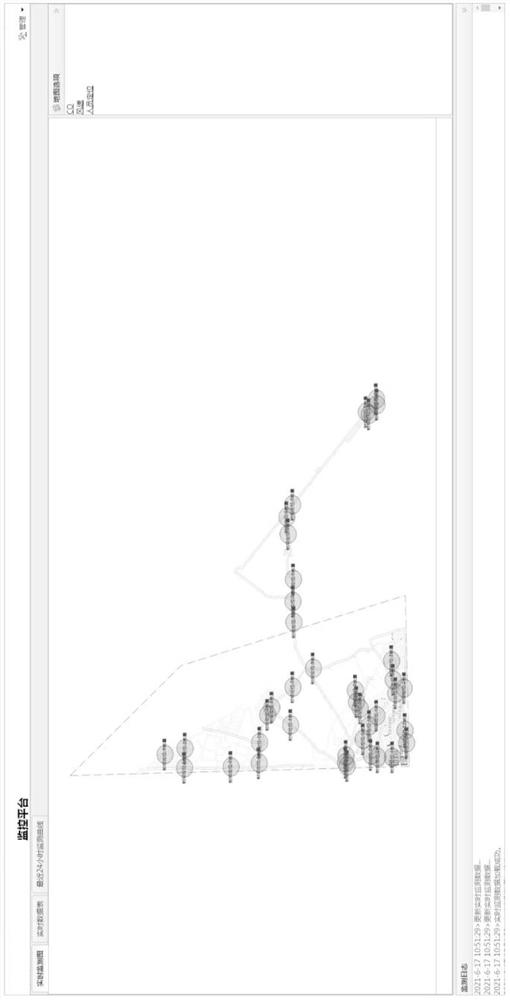

[0032] Such as Figure 1~Figure 6 , a comprehensive early warning method for underground ventilation safety based on WebGIS platform, which includes the following steps:

[0033] Step 1: Set up fan detection points; set fan start-stop monitors for high-energy-consuming fans in the underground ventilation system, and fan start-stop monitors are connected to intelligent mine monitors and connected to the WebGIS platform; the purpose of this step is to check To clarify the current situation of underground ventilation and wind quality monitoring system, clarify the quantity, model and location of ventilation equipment, establish the conditions for remote frequency conversion control for fans with high energy consumption and no remote frequency conversion control function, and establish network data communication connections to facilitate calculation of actual production capacity and the need for ventilation capacity.

[0034] Step 2, personnel positioning, for underground operato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com