Downhole cannon-hit-resistant air duct preparation method and cannon-hit-resistant air duct

A technology of air duct and liner, which is applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc. It can solve problems such as poor tear resistance and impact resistance, intolerance to blasting, and heavy weight, and achieve strong Impact resistance, simple preparation process and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

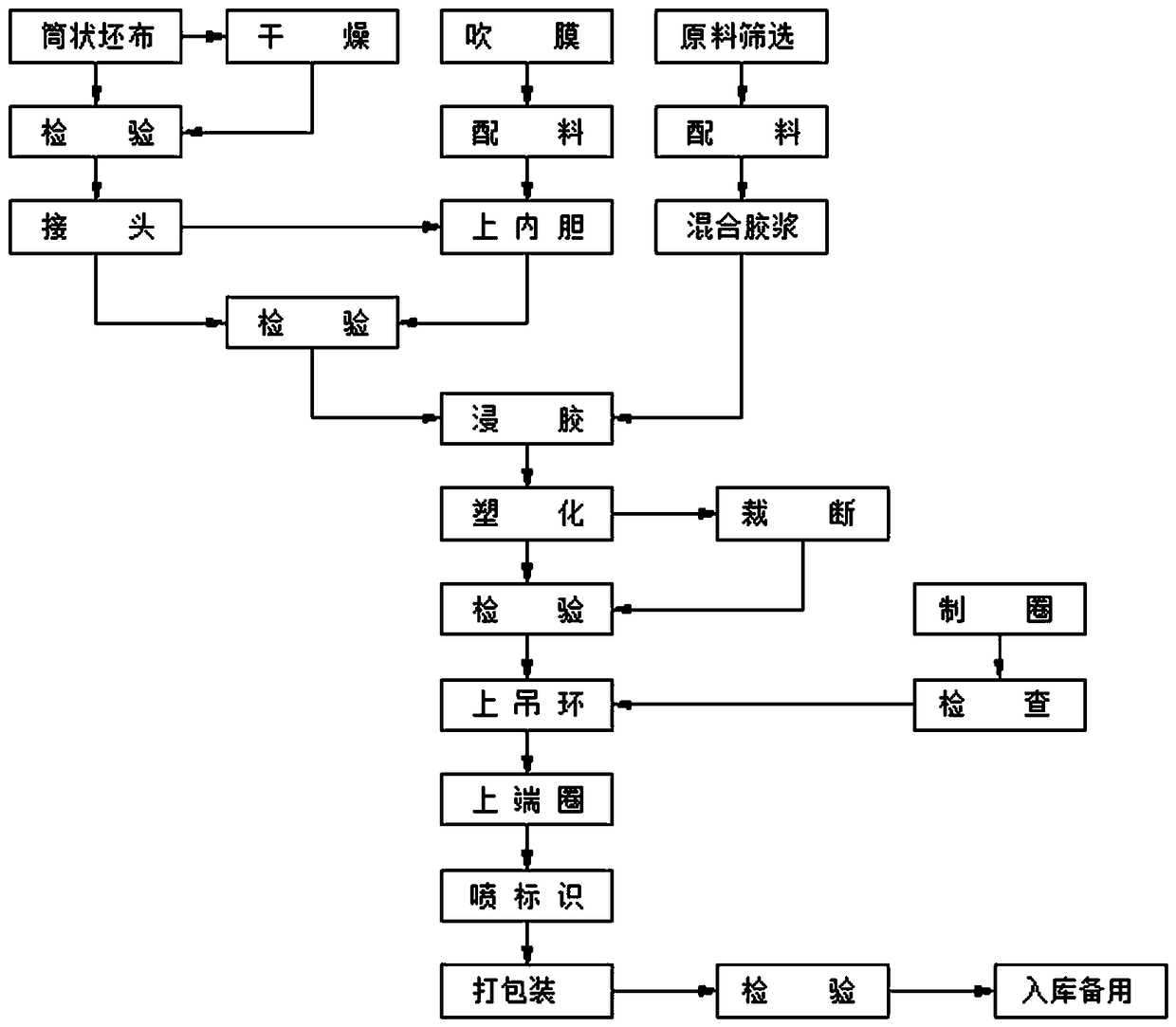

[0032] A method for preparing an underground anti-burst collapse air tube, the steps of the preparation method are as follows:

[0033] Step 1, mixing glue: 31 parts of paste resin, 22 parts of dibutyl ester, 10 parts of liquid chlorinated paraffin, 8.2 parts of hydrated aluminum oxide, 5.1 parts of flame retardant, and 3.9 parts of antimony trioxide in the composition and parts by weight , 1.6 parts of zinc borate, 3.2 parts of electrostatic agent, 0.2 part of rubber scarlet, 0.8 part of dibasic lead phosphite and 0.6 part of tribasic lead sulfate are made into the mortar used to prepare explosion-proof air ducts, and the powder ingredients are put into the preparation , put in the solvent and mix well, put in other aniseed materials, fully beat the rubber material, and park the rubber material for 48 hours before use;

[0034] Step 2. Inspection: Check the gray fabric first, if there are defects, it needs to be repaired by stitching, check the inner liner, and perform heat s...

Embodiment 2

[0054] A method for preparing an underground anti-burst collapse air tube, the steps of the preparation method are as follows:

[0055] Step 1, mixing glue: 25 parts of paste resin, 16 parts of dibutyl ester, 8 parts of liquid chlorinated paraffin, 6.2 parts of hydrated aluminum oxide, 4.1 parts of flame retardant, and 3.2 parts of antimony trioxide in the composition and parts by weight , 1.3 parts of zinc borate, 2.1 parts of electrostatic agent, 0.16 part of rubber scarlet, 0.6 part of dibasic lead phosphite and 0.5 part of tribasic lead sulfate are made into the mortar used to prepare explosion-proof air ducts, and the powder ingredients are put into the preparation , put in the solvent and mix well, put in other aniseed materials, fully beat the rubber material, and park the rubber material for 48 hours before use;

[0056] Step 2 to step 7 are the same as in Embodiment 1.

Embodiment 3

[0058] A method for preparing an underground anti-burst collapse air tube, the steps of the preparation method are as follows:

[0059] Step 1, mixing glue: 35 parts of paste resin, 23 parts of dibutyl ester, 11 parts of liquid chlorinated paraffin, 9.6 parts of hydrated aluminum oxide, 6.5 parts of flame retardant and 4.6 parts of antimony trioxide in the composition and parts by weight , 2.5 parts of zinc borate, 4.1 parts of electrostatic agent, 0.32 part of rubber scarlet, 0.9 part of dibasic lead phosphite and 0.8 part of tribasic lead sulfate are made into the mortar used to prepare explosion-proof air ducts, and the powder ingredients are put into the preparation , put in the solvent and mix well, put in other aniseed materials, fully beat the rubber material, and park the rubber material for 48 hours before use;

[0060] Step 2 to step 7 are the same as in Embodiment 1.

[0061]The flame retardant described in the above examples is a halogen-free flame retardant Doher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com