Laser aiming reference object-free aircraft magnetic heading calibration method

A technology of laser aiming and calibration method, applied in measuring devices, instruments, etc., can solve the problems of high safety risk, difficult operation, fuel consumption, etc., and achieve the effect of reducing safety risk, easy operation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

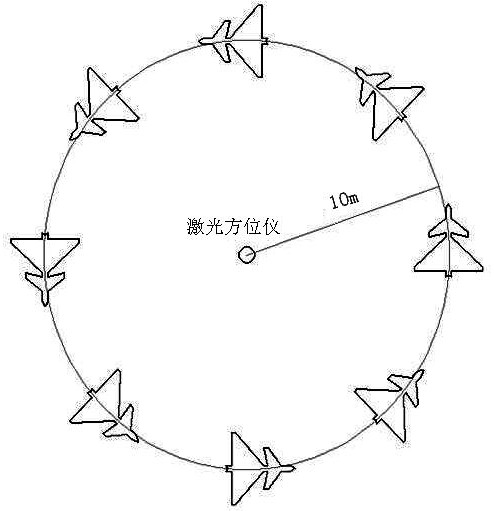

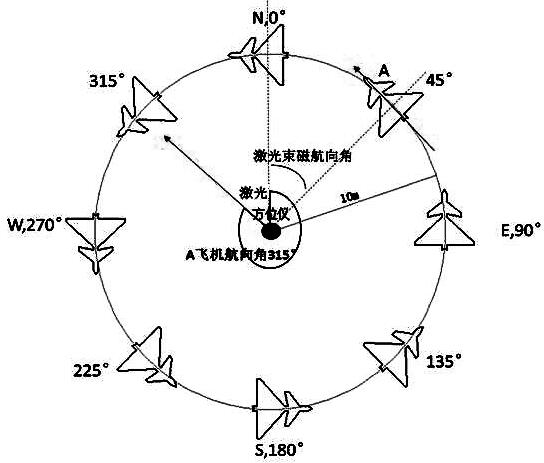

[0034] see figure 1 and figure 2 , a method for calibrating an aircraft magnetic heading with laser aiming without a reference object, comprising the following steps:

[0035] a. Install the target board on the longitudinal axis under the nose of the aircraft, and then tow the aircraft to the calibration site in an open area;

[0036] b. Place the laser azimuth on a tripod in the center of the calibration site, and read the laser heading through the compass scale of the laser azimuth;

[0037] c. Use the laser azimuth to emit lasers in the directions of 0°, 45°, 90°, 135°, 180°, 225°, 270° and 315° in sequence, and mark them on the calibration site;

[0038]d. Tow the aircraft around the center of the calibration site, and then turn it at 0-45°, 45-90°, 90-135°, 135-180°, 180-225°, 225-270°, 270-315° and 315- Stop the aircraft at any position within the eight intervals of 360°;

[0039] e. The laser is fired at the target board through the laser azimuth. When the laser be...

Embodiment 2

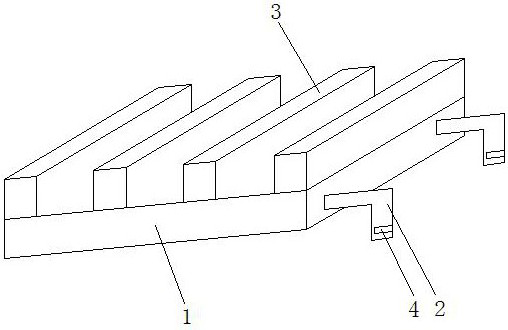

[0043] see Figure 1-Figure 3 , a method for calibrating an aircraft magnetic heading with laser aiming without a reference object, comprising the following steps:

[0044] a. Install the target board on the longitudinal axis under the nose of the aircraft, and then tow the aircraft to the calibration site in an open area;

[0045] b. Place the laser azimuth on a tripod in the center of the calibration site, and read the laser heading through the compass scale of the laser azimuth;

[0046] c. Use the laser azimuth to emit lasers in the directions of 0°, 45°, 90°, 135°, 180°, 225°, 270° and 315° in sequence, and mark them on the calibration site;

[0047] d. Tow the aircraft around the center of the calibration site, and then turn it at 0-45°, 45-90°, 90-135°, 135-180°, 180-225°, 225-270°, 270-315° and 315- Stop the aircraft at any position within the eight intervals of 360°;

[0048] e. The laser is fired at the target board through the laser azimuth. When the laser beam i...

Embodiment 3

[0052] see Figure 1-Figure 3 , a method for calibrating an aircraft magnetic heading with laser aiming without a reference object, comprising the following steps:

[0053] a. Install the target board on the longitudinal axis under the nose of the aircraft, and then tow the aircraft to the calibration site in an open area;

[0054] b. Place the laser azimuth on a tripod in the center of the calibration site, and read the laser heading through the compass scale of the laser azimuth;

[0055] c. Use the laser azimuth to emit lasers in the directions of 0°, 45°, 90°, 135°, 180°, 225°, 270° and 315° in sequence, and mark them on the calibration site;

[0056] d. Tow the aircraft around the center of the calibration site, and then turn it at 0-45°, 45-90°, 90-135°, 135-180°, 180-225°, 225-270°, 270-315° and 315- Stop the aircraft at any position within the eight intervals of 360°;

[0057] e. The laser is fired at the target board through the laser azimuth. When the laser beam i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com