Rubber tree bark tensile strength testing device and testing method

A tensile strength and testing device technology, applied in the direction of measuring device, strength characteristics, and testing material strength by applying stable tension/pressure, can solve the problems of high cost, large influence of rubber tree, large volume, etc., and achieves simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

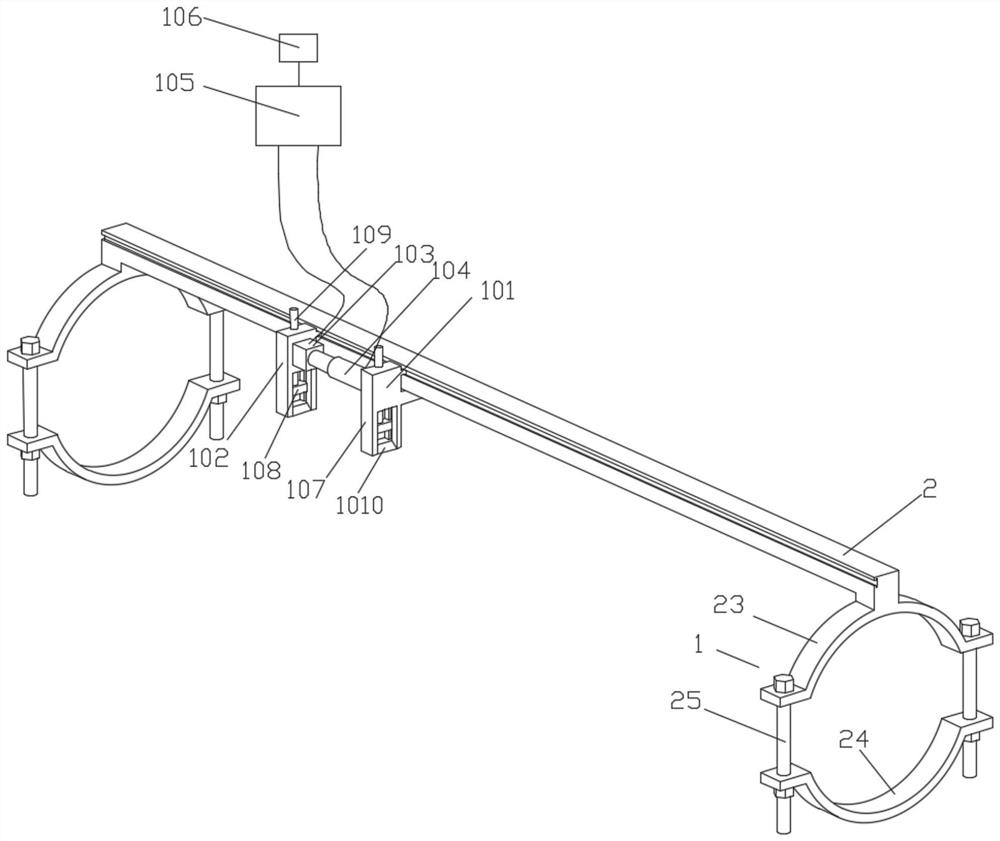

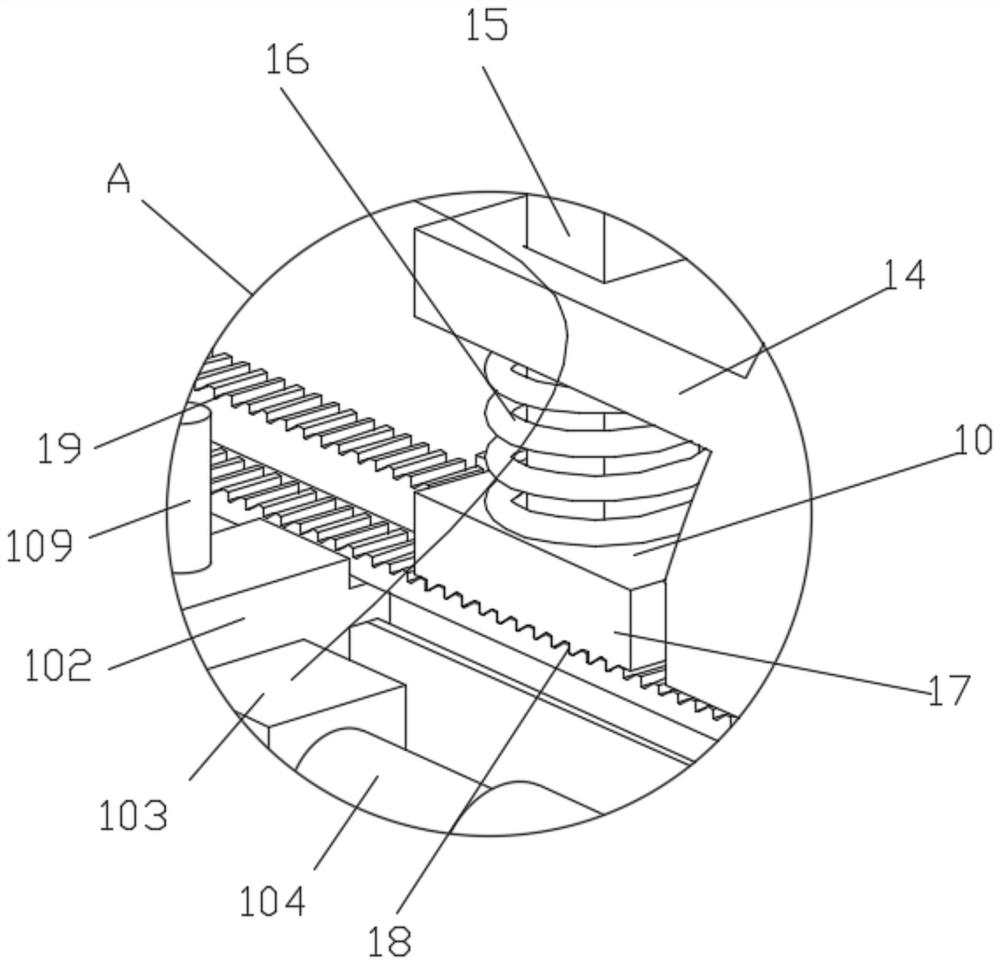

[0027] Referring to the figure, a rubber bark tensile strength testing device includes a first clamping head 101, a second clamping head 102, a linear slide rail 2, a hoop 1, a tension detector 103 and a telescopic rod 104, and the linear slide The rail 2 is fixed on the rubber tree through the hoop 1, the first clamping head 101 and the second clamping head 102 are both slidably connected with the linear slide rail 2, and one end of the telescopic rod 104 is connected to the first The clamping head 101 is fixedly connected, and the other end is provided with the tension detector 103 , and the other end of the tension detector 103 is connected with the second clamping head 102 . First utilize cutter to cut off the rubber bark in the circumferential direction of the rubber tree, then cut off the rubber bark downwards along the direction of the rubber tree trunk from the cut mark, part of the rubber tree bark is peeled off from the trunk, and then utilize the device of the presen...

Embodiment 2

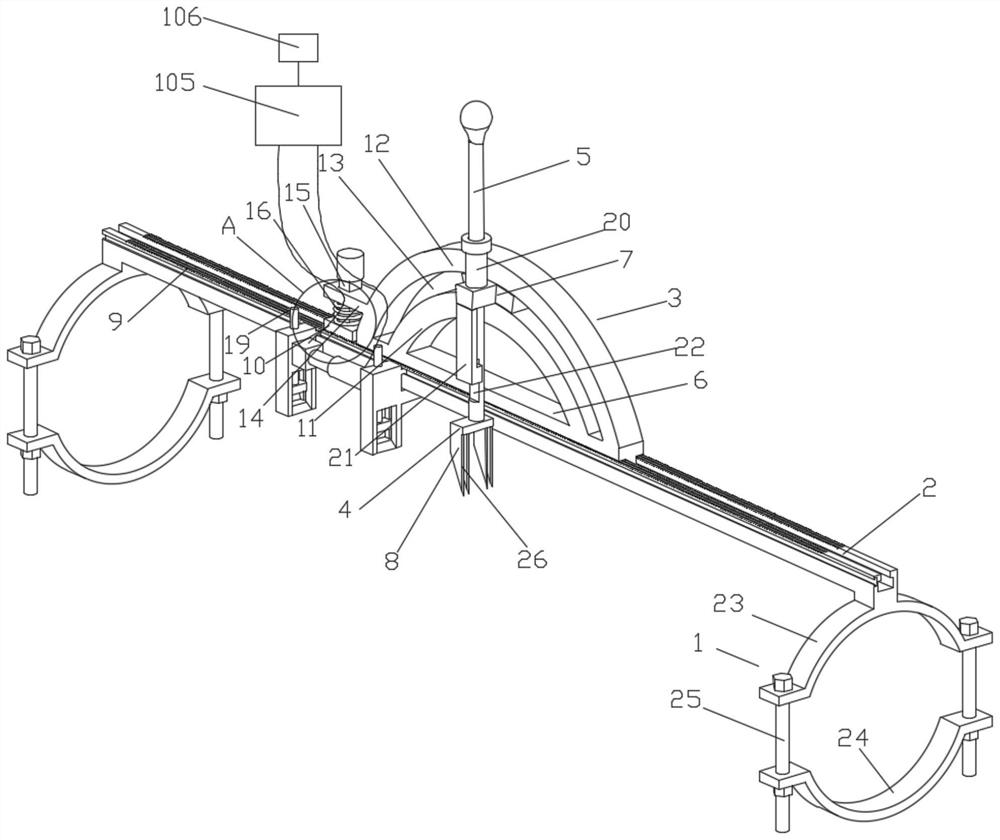

[0031] see Figure 2-5, The difference between this embodiment and Embodiment 1 is that it also includes an arc-shaped slide rail 3, a cutting knife 4 and a handle 5, the linear slide rail is provided with a first slider 6, and the first slider 6 is provided with There is the arc slide rail 3, the second slide block 7 is slidingly connected with the arc slide rail 3, the second slide block 7 is connected with the handle 5, and the lower end of the handle 5 is provided with the Described cutting knife 4, described cutting knife 4 is provided with the cutting part 8 that is used to cut into rubber bark, and the circle center of described second slide block 7 movement track is positioned at the middle of described cutting part 8, and described linear slide rail 2 is provided with There are several tooth grooves 9 , and the first slider 6 is provided with a non-return tooth block 10 that cooperates with the tooth grooves 9 .

[0032] Two hoops 1 are fixed at different height posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com