Achromatic holographic optical device and manufacturing method thereof

A technology of optical devices and manufacturing methods, applied in optical components, optical components, optics, etc., can solve the problems of large lens size, etc., and achieve the effects of reducing materials, increasing shrinkage, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

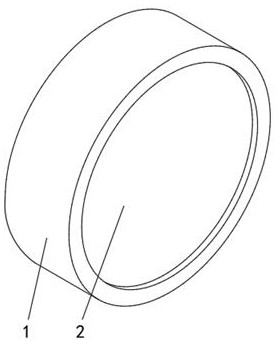

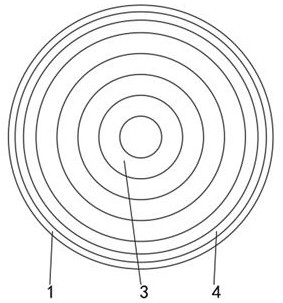

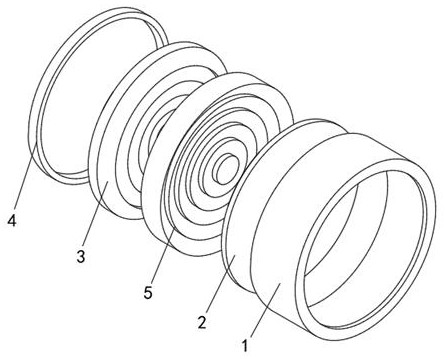

[0029] Such as Figure 1-4 As shown, the embodiment of the present invention provides an achromatic holographic optical device, including a single-sided convex lens 2, a double-sided convex lens 3, and a double-sided concave lens 5. The end faces of the single-sided convex lens 2 and the double-sided convex lens 3 are provided with stepped annular arc surfaces, and each The arc radius of the cross-sectional profile of the arc-shaped surface is consistent. This setting can reduce the axial size of the component, so that the component can be manufactured with less material, reduce the quality, and reduce the material cost. Both ends of the double-sided concave lens 5 are provided with stepped rings arc surface, and the arc radius of each arc surface section profile is consistent, which is consistent with the above-mentioned effect. The single-sided convex lens 2, the double-sided concave lens 5 and the double-sided convex lens 3 are stacked in sequence, so that the stacked parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com