A nanometer metal substrate, a preparation method thereof, and a preparation method of a circuit board containing the substrate

A nano-metal and circuit board technology, applied in the direction of circuit substrate materials, chemical instruments and methods, printed circuits, etc., can solve the problems of increased processing costs, residual stress, broken through holes, etc., to improve hardness and flame retardancy, Excellent dimensional stability and the effect of increasing surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

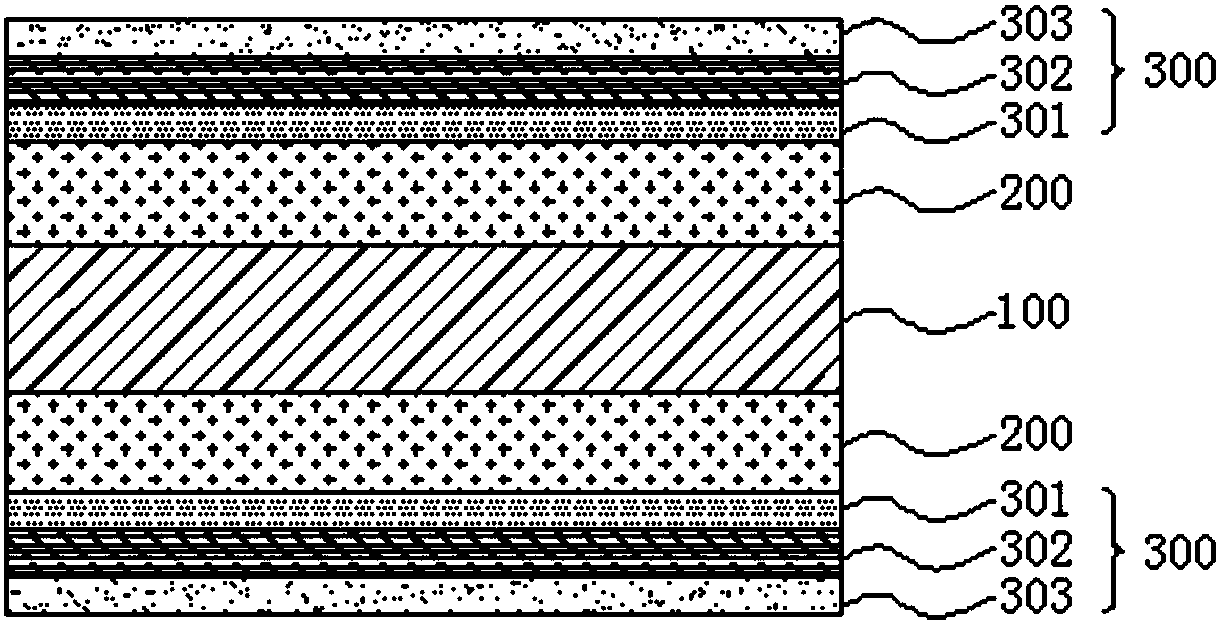

[0053] Embodiment: a kind of nanometer metal substrate, as figure 1 As shown, it includes a low thermal expansion coefficient polyimide layer 100, a roughened polyimide layer 200 formed on both sides of the low thermal expansion coefficient polyimide layer 100, and a roughened polyimide layer 200 formed on the roughened polyimide layer 200. The ultra-thin nano-metal layer 300 on the other side, the roughened polyimide layer 200 is between the low thermal expansion coefficient polyimide layer 100 and the ultra-thin nano-metal layer 300;

[0054] The ultra-thin nano-metal layer 300 includes a silver metal layer 301, a copper metal layer 302 formed on either side of the silver metal layer 301 and a nickel metal layer 303 formed on the other side of the copper metal layer 302, the silver metal layer Layer 301 is between the roughened polyimide layer 200 and the copper metal layer 302, and the copper metal layer 302 is between the silver metal layer 301 and the nickel metal layer 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com