Auxiliary decision-making method for formulating purchasing strategy in productivity recovery stage

A recovery stage and auxiliary decision-making technology, applied in the direction of complex mathematical operations, instruments, technology management, etc., to achieve the effect of reducing delivery risk, high reliability of the method, and ensuring effective implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to better understand the present invention, we will further elaborate the present invention below in conjunction with specific examples.

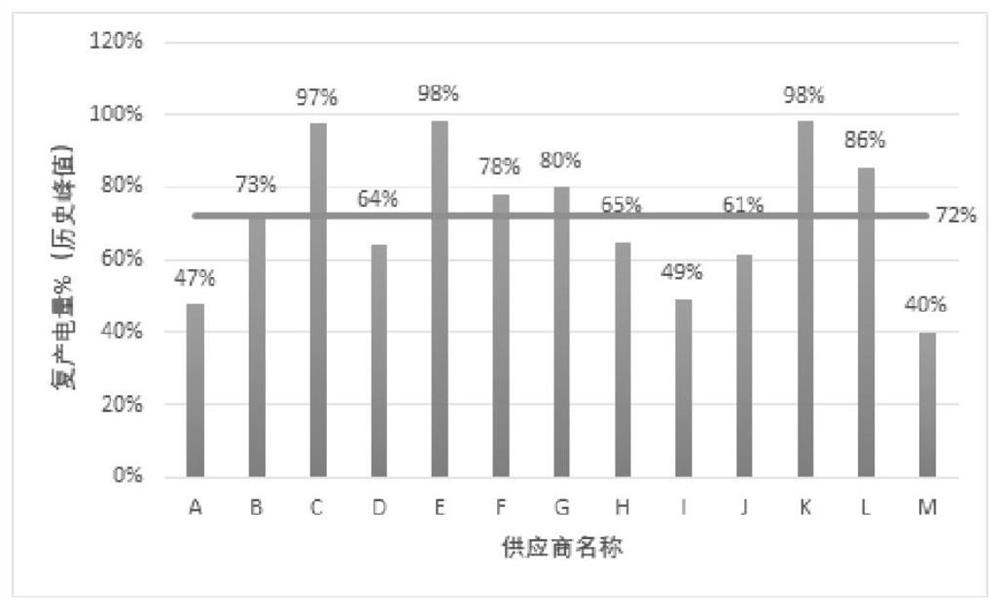

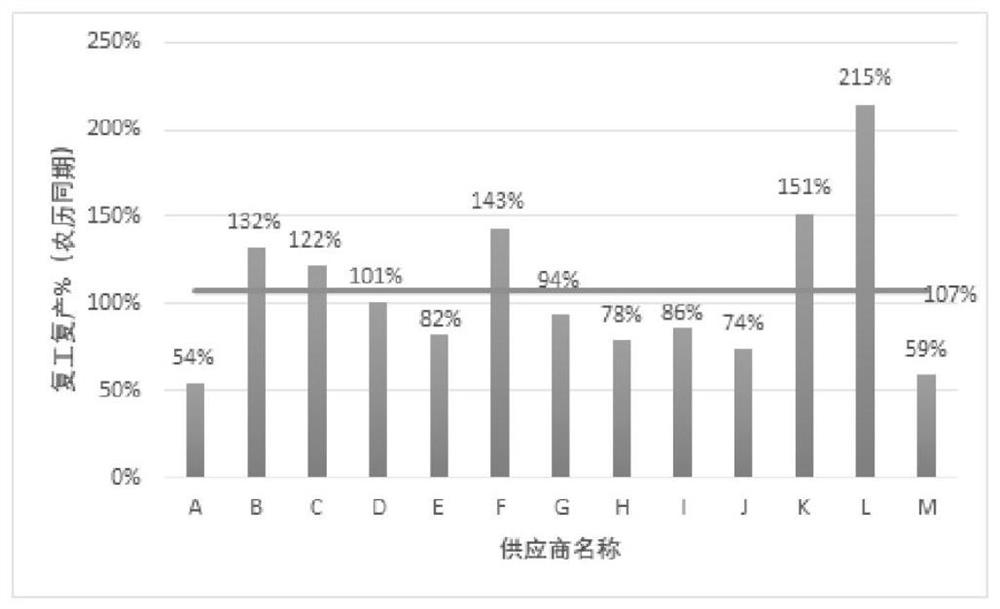

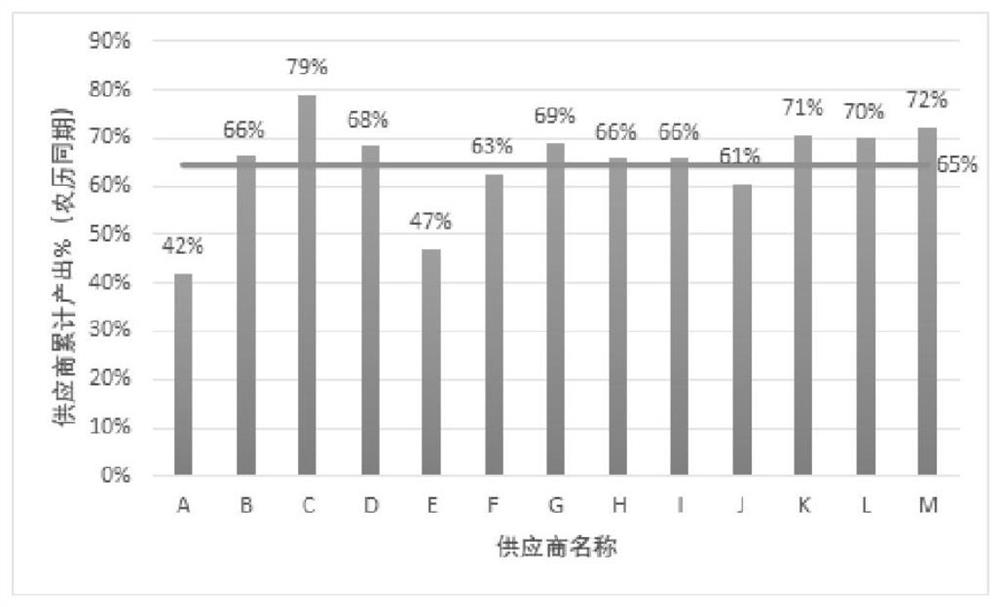

[0075] Take 13 suppliers of a material in Jiangsu Province as an example. It is in suspension from February 3, 2020 to February 9, 2020. Production will gradually resume from February 10, 2020. In order to predict the recovery of production capacity after the resumption of production, the power company analyzed its electricity consumption data of the previous year (Lunar calendar year).

[0076] Preferably, in this embodiment, a clustering algorithm is used to calculate the basic electricity consumption, including the following steps:

[0077] J1: Select the historical daily electricity consumption data of the supplier to be analyzed as the total sample size, randomly select k samples of the daily electricity consumption data as the initial clustering center point, and divide each sample into the nearest cluster according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com