New energy automobile battery wire harness production process

A new energy vehicle and production process technology, applied in the manufacture of wire harnesses, circuits, electrical components, etc., can solve problems that affect the progress of the production process and the quality of finished products, the efficiency of the wire harness detection part is general, and the detection function of the wire harness production process is single, etc., to achieve strengthening Comprehensiveness of testing, improvement of finished product quality, and the effect of optimizing production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

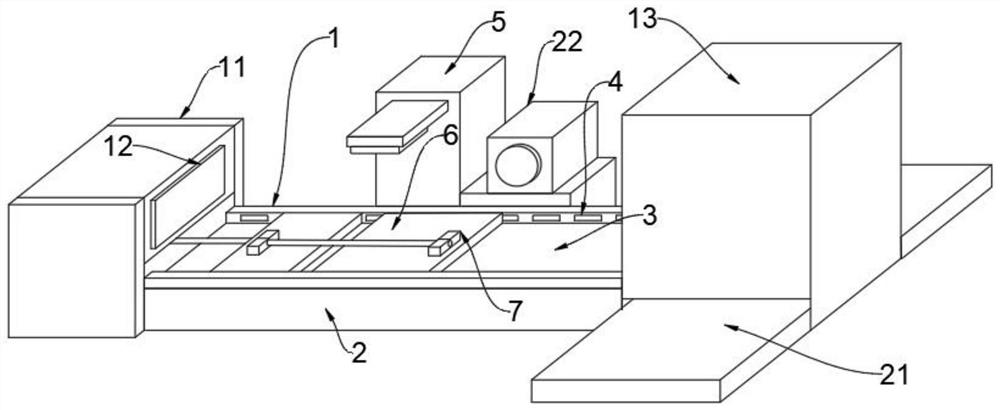

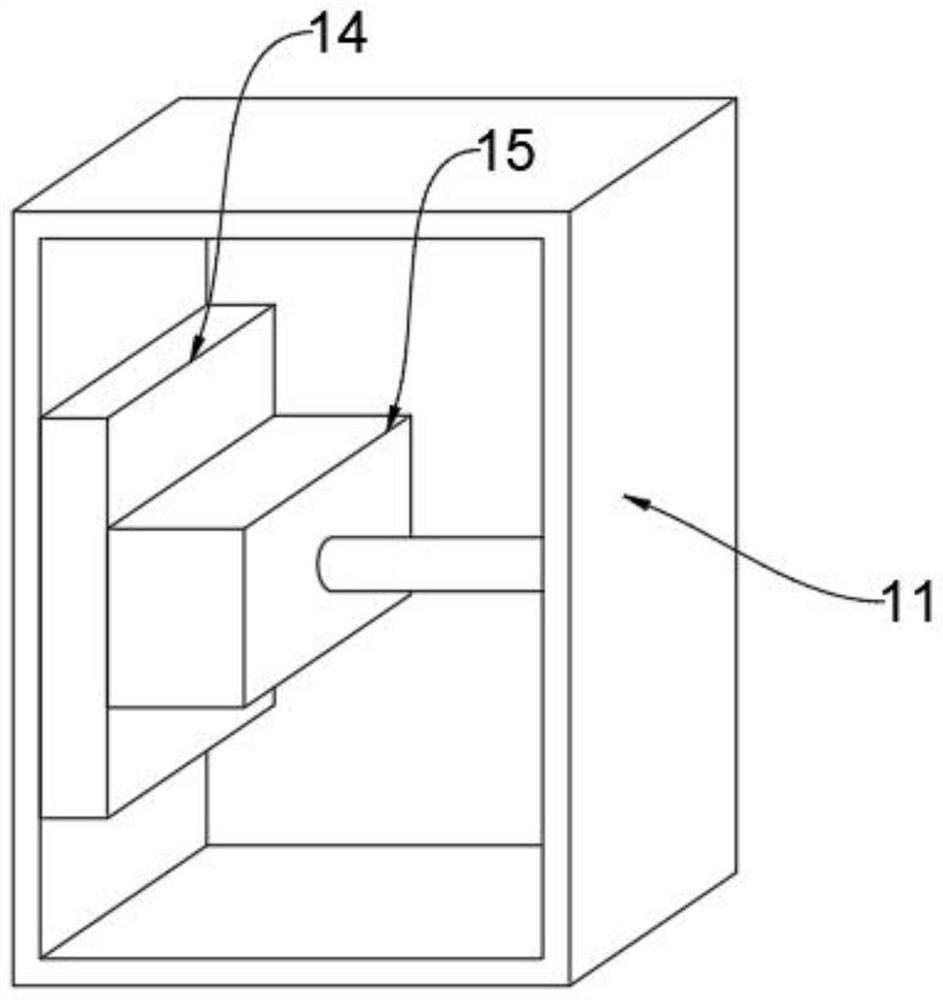

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

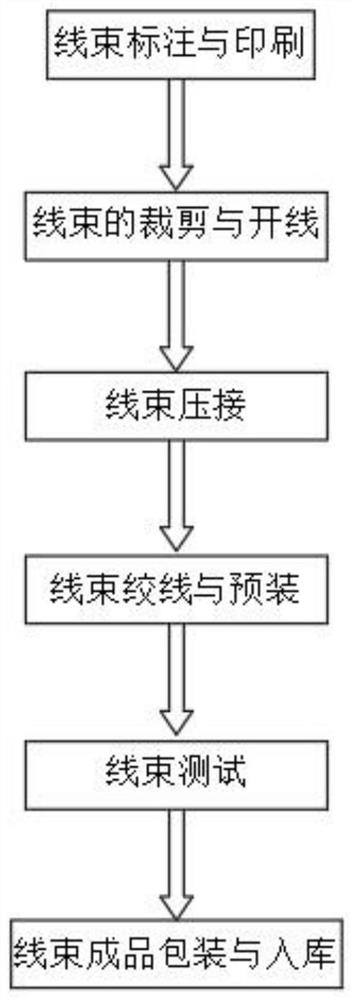

[0031] see Figure 1-5 , an embodiment provided by the present invention: a new energy vehicle battery wiring harness production process, comprising the following steps:

[0032] Step 1: Marking and printing of wire harness: Mark and print the wire body required for production, print different colors according to different wire types, and mark different wire diameters;

[0033] Step 2: Cutting and opening of the wire harness: According to the requirements of the drawings, cut and mark the size of the wire harness wires, and rely on the automatic cutting machine to cut the wires, strip the wires, and cut them into appropriate lengths, and install them as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com