Automated insect rearing system and container

A technology for containers and insects, applied in the field of automatic insect rearing systems and containers, which can solve the problems of biodiversity loss and achieve the effect of increasing growth, reproduction and growth improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

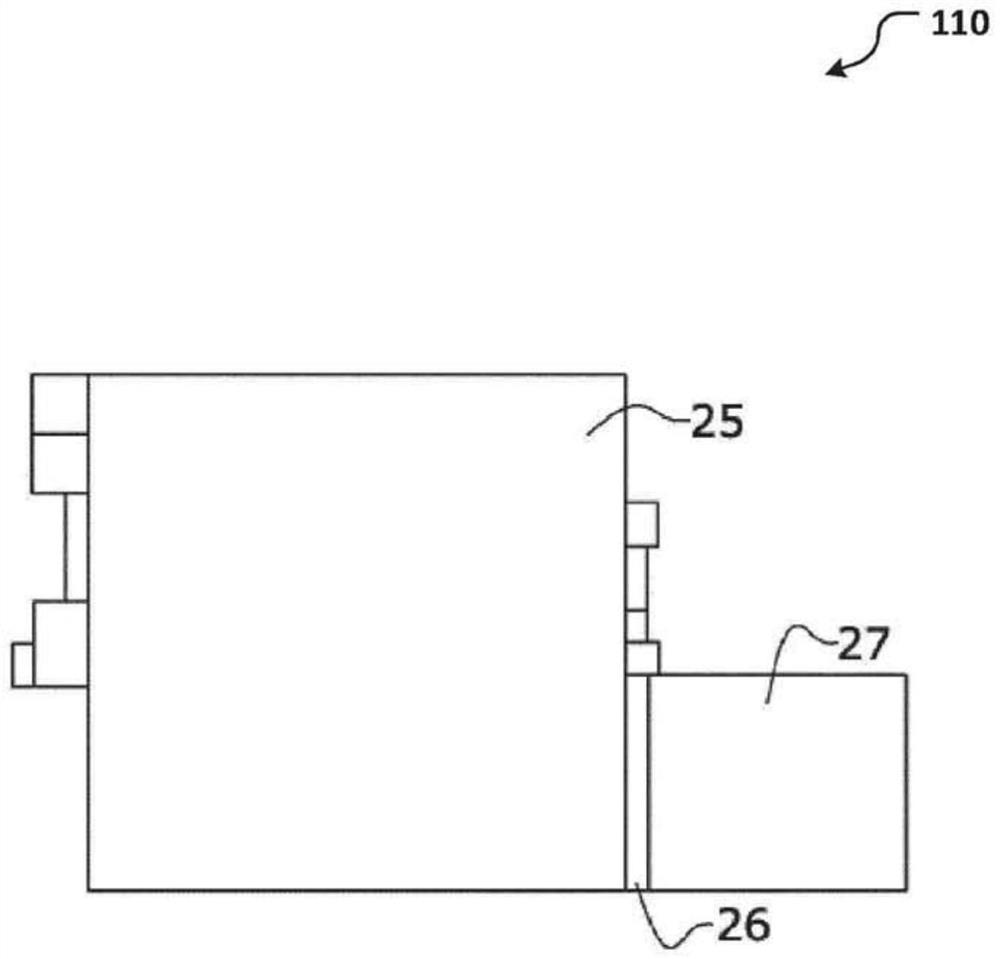

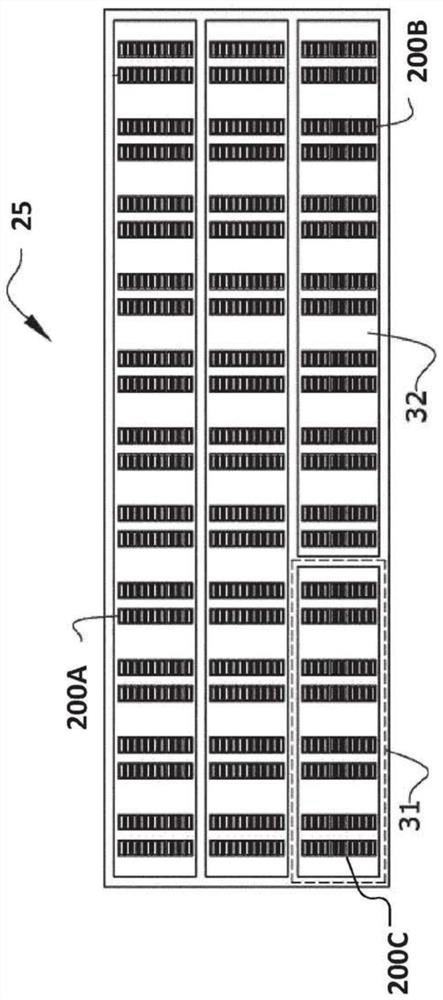

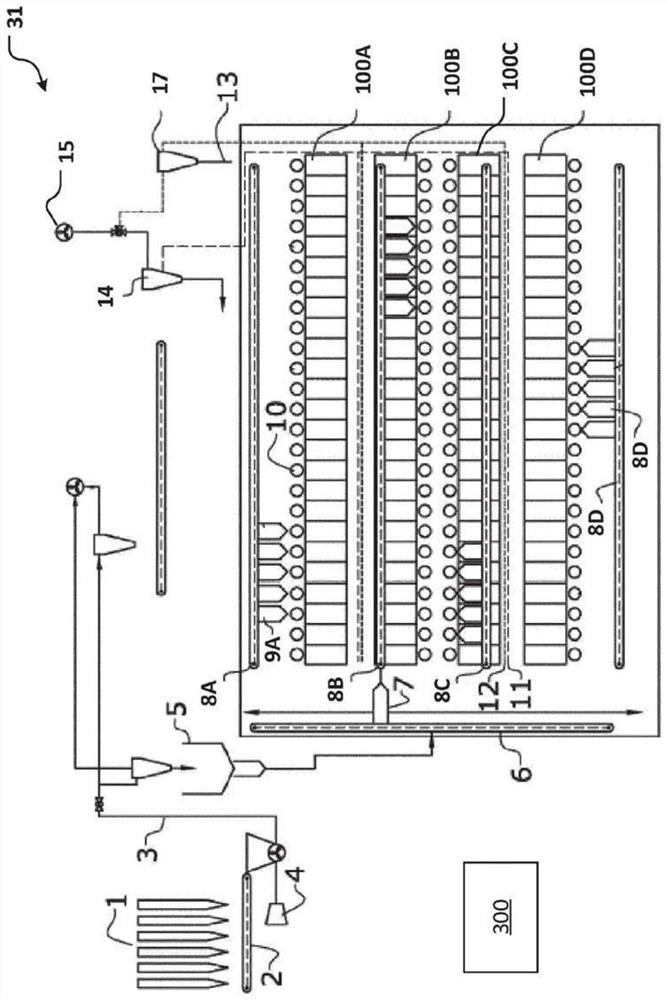

[0057] The present disclosure provides an automated insect rearing facility for insect reproduction and growth. In at least one example, the insects farmed in the provided facility are of the order Coleoptera (eg, beetles), such as Tenebrio molitor beetles (commonly known as flour worm beetles). In other examples, the provided facilities can be used to rear other suitable insects, such as flies. Insects are reared in rearing modules containing multiple tray groups. The provided facility includes components in communication with a control unit that directs and controls said components according to predetermined instructions and / or in response to feedback from a number of different sensors. Sensors may include light sensors, humidity sensors, temperature sensors, weight sensors, moisture sensors, motion sensors, and / or video sensors, among other suitable sensors. Thus, the components can perform various facility operations autonomously via instructions from the control unit wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com