Reaction kettle for titanium dioxide processing

A reaction kettle and titanium dioxide technology, applied in grain processing, chemical/physical/physicochemical processes, chemical instruments and methods, etc., can solve problems such as low output efficiency and easy agglomeration of titanium dioxide raw materials, so as to avoid agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

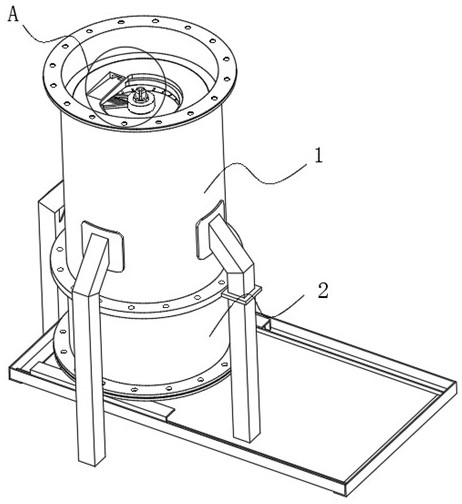

[0043] Embodiment: A reaction kettle for processing titanium dioxide, comprising: a tank body 1, a crushing assembly 2 and a reaction cylinder 3 are sequentially arranged in the tank body 1 from top to bottom, and the reaction cylinder 3 in this example can be combined with the actual processing method Corresponding internal changes are made, and other components, such as heating and stirring, are all existing common knowledge, and this example does not go into details, and is not shown in the illustration.

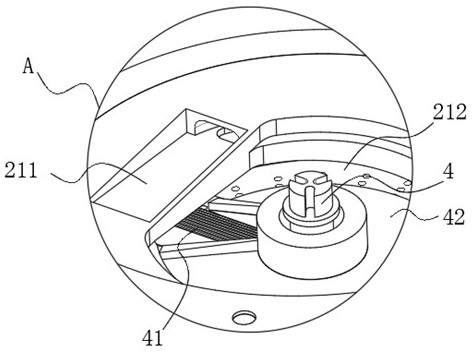

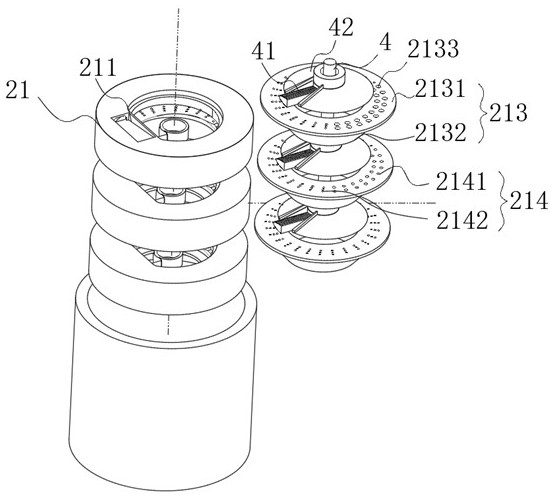

[0044] The crushing assembly 2 is composed of several grinding wheels 21, which are regularly distributed in the tank body 1 from top to bottom. The whole powder wheel 21 is an annular structure in which the middle part is provided with openings, and the connecting shaft 4 is vertically arranged at the middle part of the powder grinding wheel 21, and the outer end of the connecting shaft 4 is sequentially covered with three retaining rings 42 from top to bottom. The retai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com