Processing method of power axle

A processing method and technology for power shafts, which are applied in the directions of axles, wheels, transportation and packaging, can solve the problems of high scrap rate, high production cost, high force strength of power shaft bridges, etc., and achieve high processing accuracy, low cost, Solve the effect of high scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

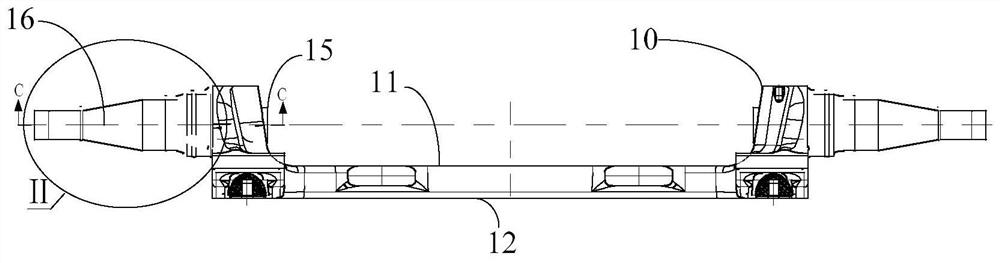

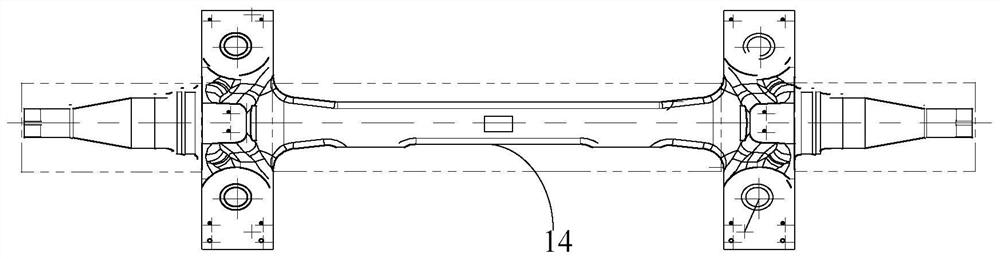

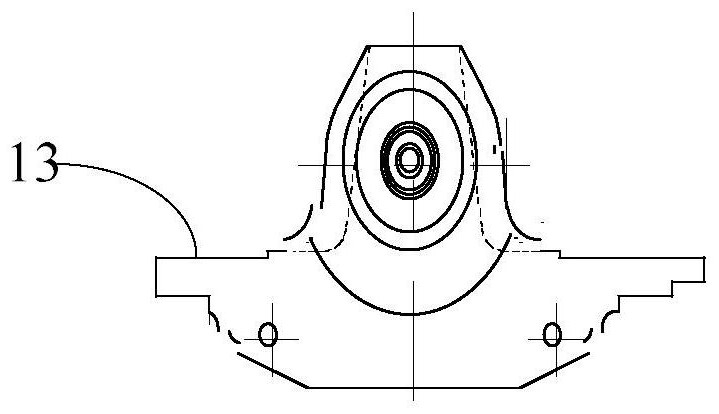

[0021] The present invention proposes a processing method of a power shaft bridge, referring to Figure 1 to Figure 5 The processing method of the power axle bridge includes: the power axle bridge includes a U-shaped seat body 10, the U-shaped seat body 10 includes an inner rim and a side surface 12 concave inward, and the inner rim includes an upper mounting surface 11 and the bottom surface 12; the two ends of the U-shaped seat body 10 are provided with a sink platform 13; the opposite surface of the inner file is provided with a middle boss 15; shaft 16; the central shaft 16 is located on the same central line; the center of the central shaft 16 is provided with a first through hole; the upper end surface of the sinking platform 13 is provided with a mounting hole; the two ends of the central shaft 16 are provided with thread.

[0022] The processing method of the power axle bridge comprises the following steps:

[0023] Casting-marking-rough milling bottom surface 12-rou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap