Assembled type green building and construction method thereof

A green building and prefabricated technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of insufficiency of building insulation, large energy consumption, etc., and achieve the effects of improving thermal insulation effect, improving practicability, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

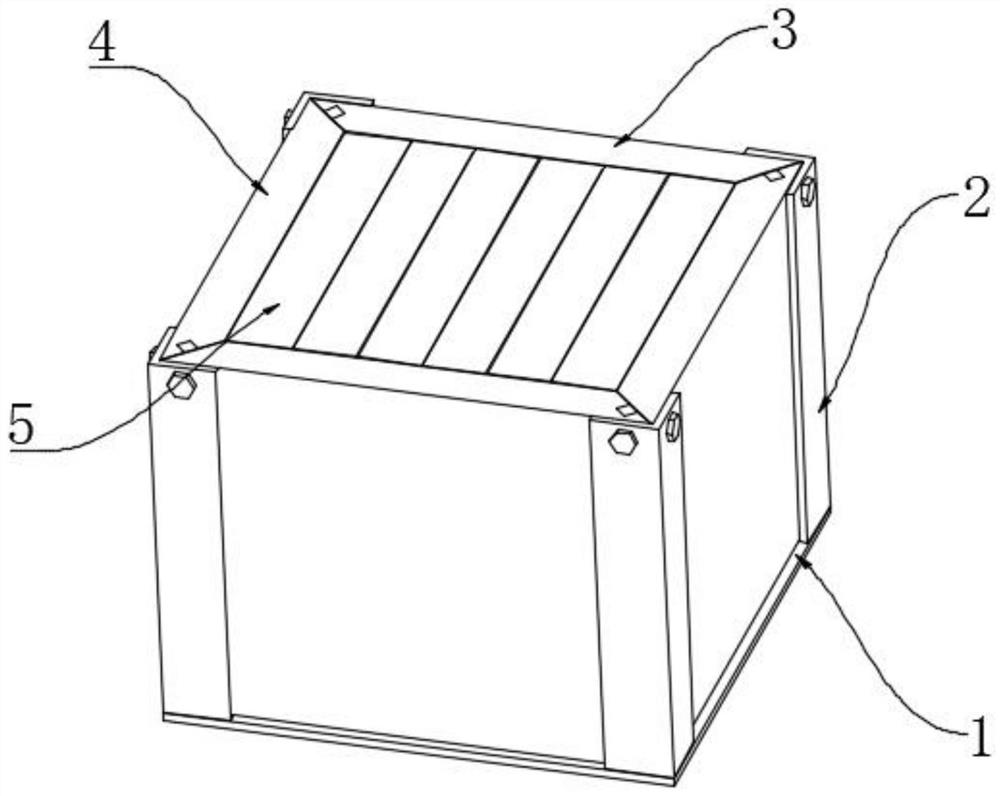

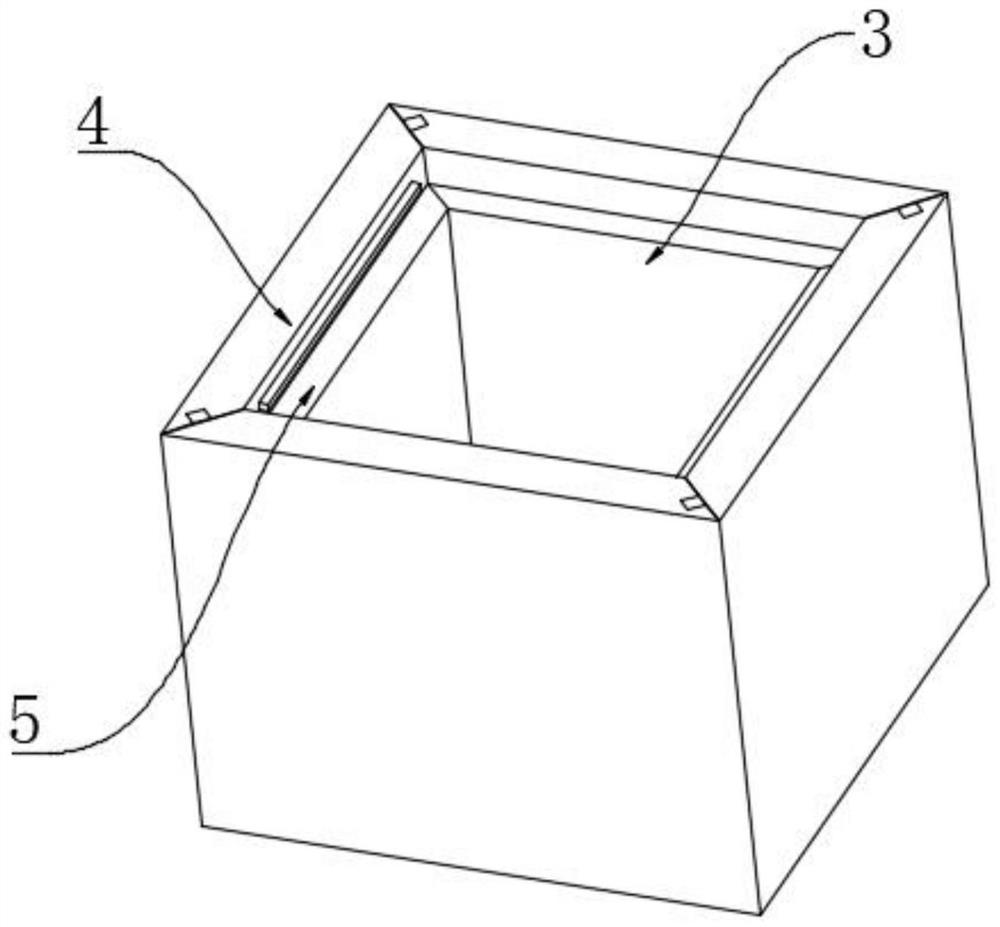

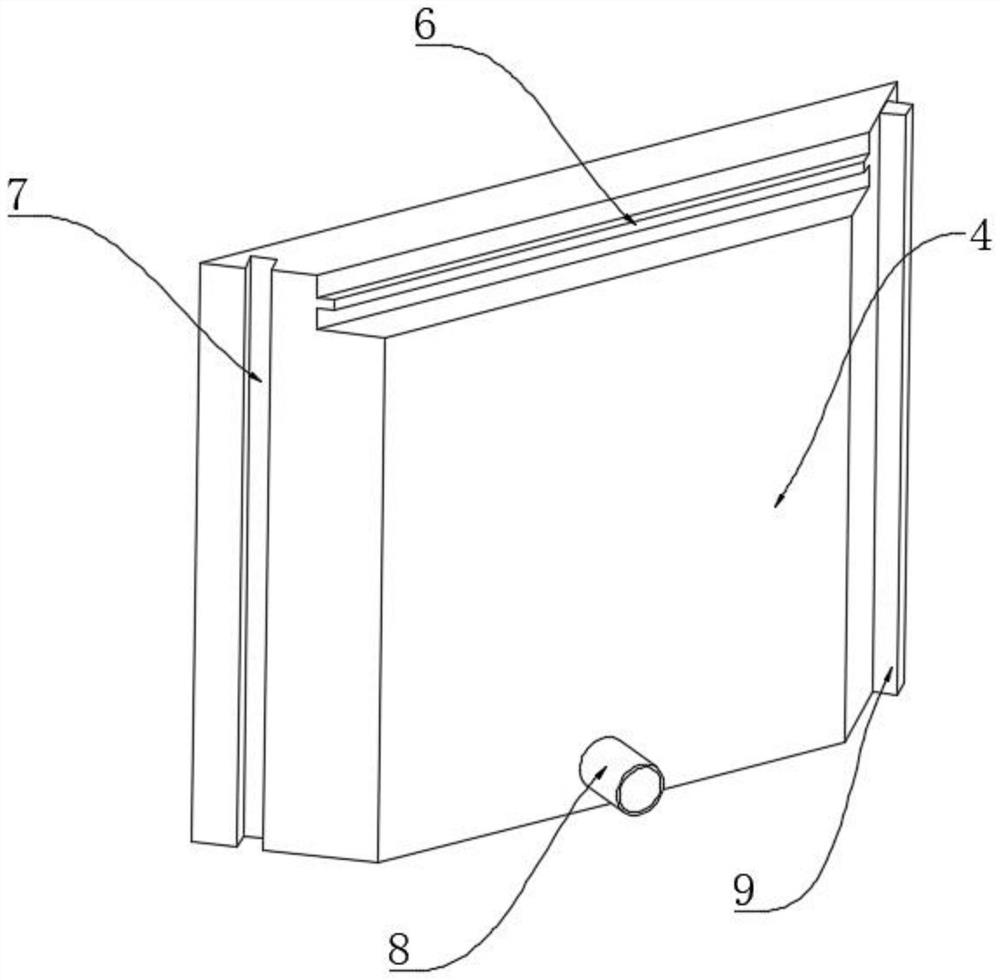

[0037] A prefabricated green building, such as Figure 1-7As shown, it includes a building foundation 1, a first wall panel 3, a second wall panel 4, and a closed top panel 5; the top outer wall of the building foundation 1 is fixedly connected with evenly distributed support limit plates 2; The outer wall of one side of the two wall panels 4 is respectively slidably connected to the inner wall of one side of the support limiting plate 2; The outer wall of the other side of the plate 4 is fixedly connected to the limiting link 9; the inner wall of the top end of the second wall plate 4 is fixedly connected with a limit rod 6; the outer wall of the bottom end of the closed top plate 5 is fixedly connected to the inner wall of the top end of the first wall plate 3; The inner wall is processed with a built-in groove 14; the inner wall of one side of the built-in groove 14 is slidably connected to the outer wall around the limit rod 6; the inner walls of the first wall panel 3 and...

Embodiment 2

[0042] A construction method for a prefabricated green building specifically includes the following steps:

[0043] S1: Select an address and make building foundation 1;

[0044] S2: Fix the support limit plate 2 on the building foundation 1;

[0045] S3: Slide the first wall panel 3 and the second wall panel 4 into the support limit plate 2 by the crane, and ensure that the limit link 9 on the first wall panel 3 is placed on the limit of the second wall panel 4 In the position connecting groove 7, the limit link 9 on the second wall panel 4 is placed in the position limit connecting groove 7 on the first wall panel 3;

[0046] S4: set bolts on the support limit plate 2 to fix the first wall plate 3 and the second wall plate 4;

[0047] S5: use a crane to place the closed top plate 5 on the top of the first wall plate 3 and the second wall plate 4, and ensure that the built-in groove 14 on the closed top plate 5 is placed on the limit rod 6 of the second wall plate 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com