Vacuum metering casting device

A vacuum and casting material technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of easy occurrence of pores, complicated devices, waste of time, etc., to prolong the service life, shorten the casting time, and simplify the casting. The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

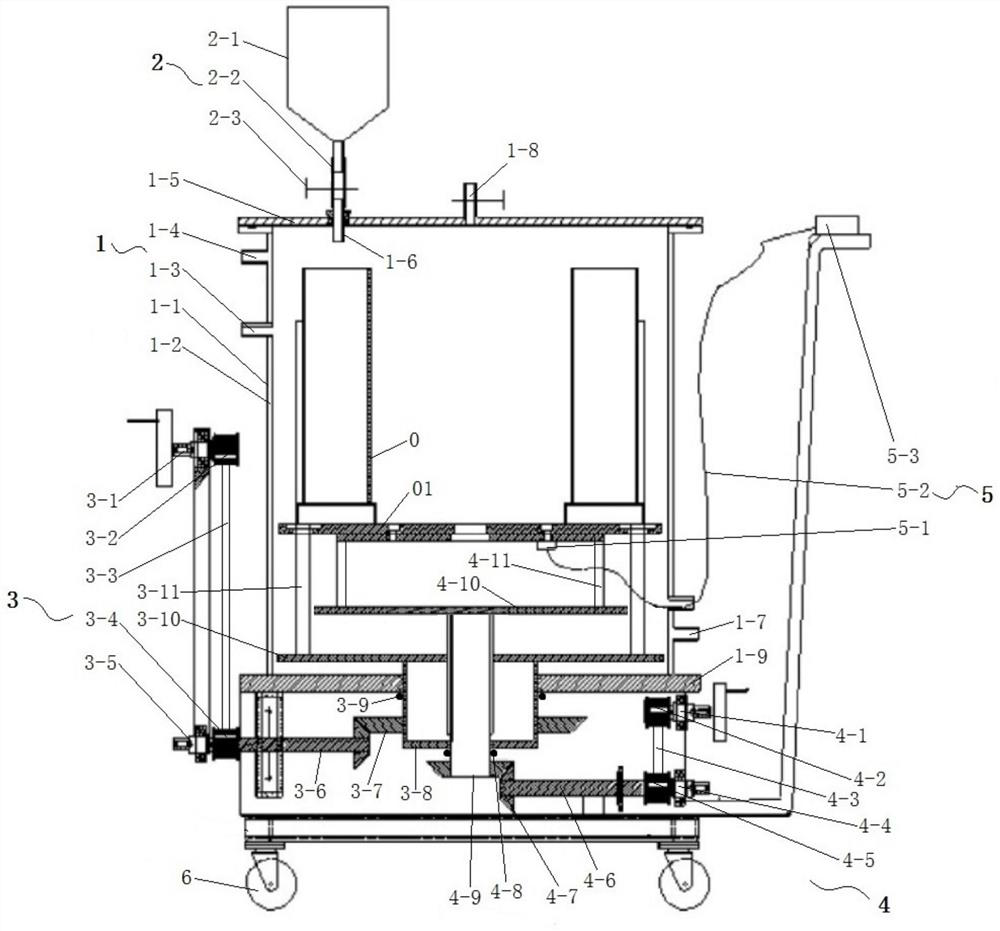

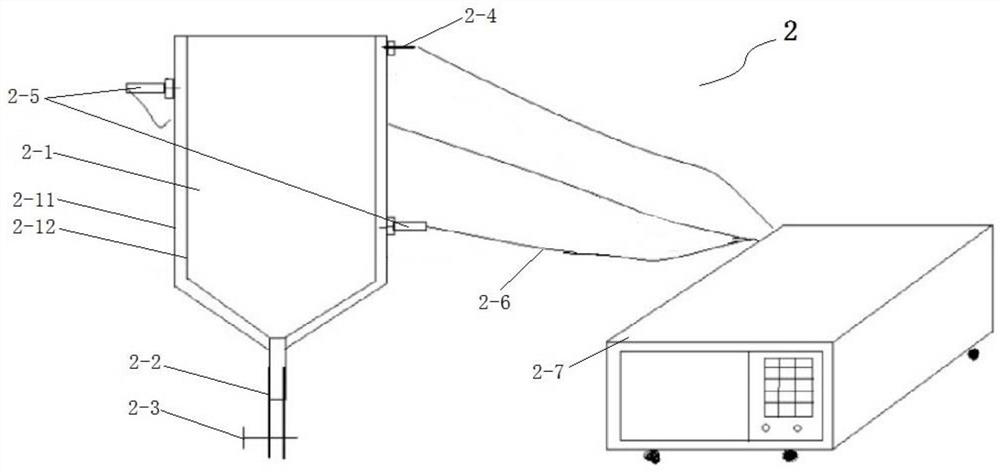

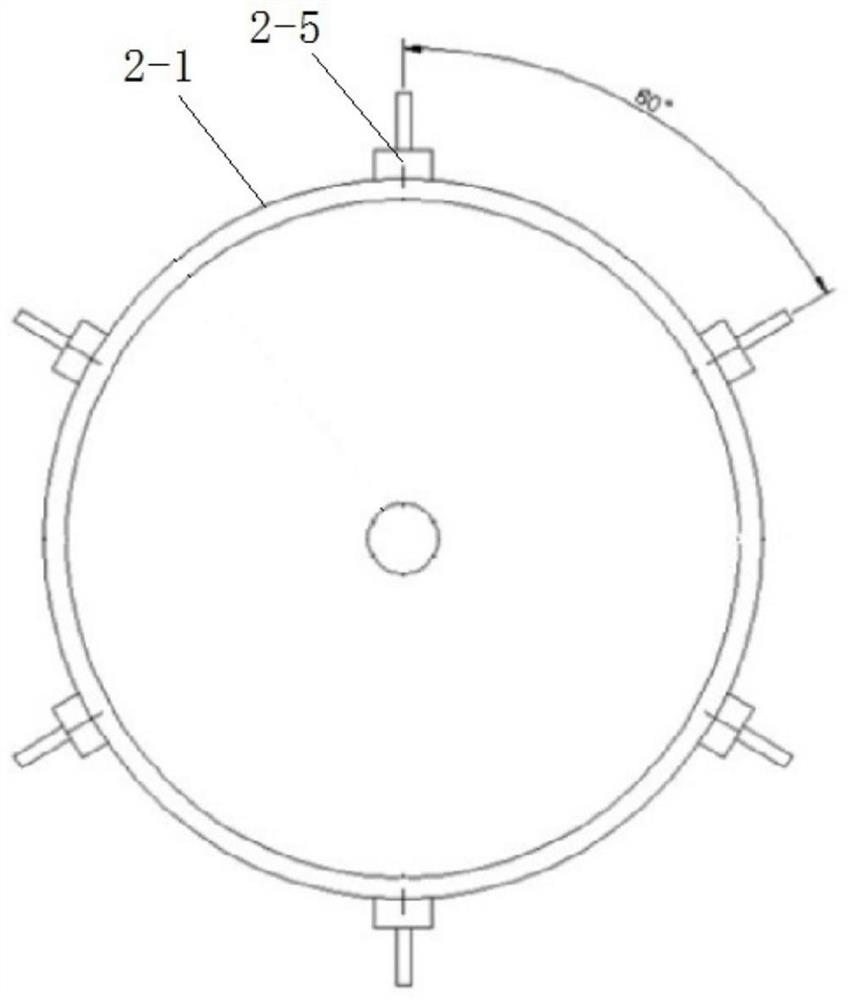

[0040] like Figure 1-4 As shown, this embodiment discloses a vacuum metering casting device, which includes a casting tank 1, the casting tank 1 is a cylinder with a sealed surrounding and a vacuum in the inner cavity, and the inner cavity of the casting tank 1 is provided with a space for placing the engine 0, The upper surface of the casting tank body 1 is provided with a casting port 1-6 communicating with its inner cavity, and also includes a casting mechanism 2; the casting mechanism 2 includes a casting hopper 2-1, a casting pipe 2-2, a casting valve 2-3, and a casting hopper 2 -1 is a cylindrical structure with openings at both ends, the casting tube 2-2 is coaxially arranged under the casting hopper 2-1, and the lower port of the casting hopper 2-1 coincides with the upper port of the casting tube 2-2, and the casting tube 2-2 It matches the structure of the casting port 1-6, and the casting pipe 2-2 communicates with the inner cavity of the casting tank body 1 throug...

Embodiment 2

[0080] This embodiment discloses the instructions for use of the vacuum metering casting device of embodiment 1, specifically as follows:

[0081] (1) Place the engine: place 8 Ф50×300mm engines evenly and sequentially on the carrier plate 01, align the engine ports 1-6 with the casting ports 1-6 of the tank cover 1-5, and each engine port is approximately located on a concentric circle;

[0082] (2) Adjust the distance between the upper end of the engine 0 and the tank cover 1-5: through the lifting drive mechanism 4, the distance between the upper end of the engine 0 and the tank cover 1-5 is 100mm, place the tank cover 1-5, and open the hot water circulation system (that is, through The cooperation of the hot water inlet 1-7 and the hot water outlet 1-4 circulates the hot water in the first interlayer 1-2);

[0083] (3) Place the casting hopper: place the connected casting hopper 2-1 at the casting port, close the casting valve 1-6, add propellant slurry to the casting hopp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com