Machining apparatus

一种加工装置、工作台的技术,应用在研磨装置、磨削驱动装置、金属加工设备等方向,能够解决卡盘工作台磨削加工不恒定等问题,达到抑制厚度偏差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, a processing apparatus according to an embodiment of the present invention will be described in detail with reference to the drawings.

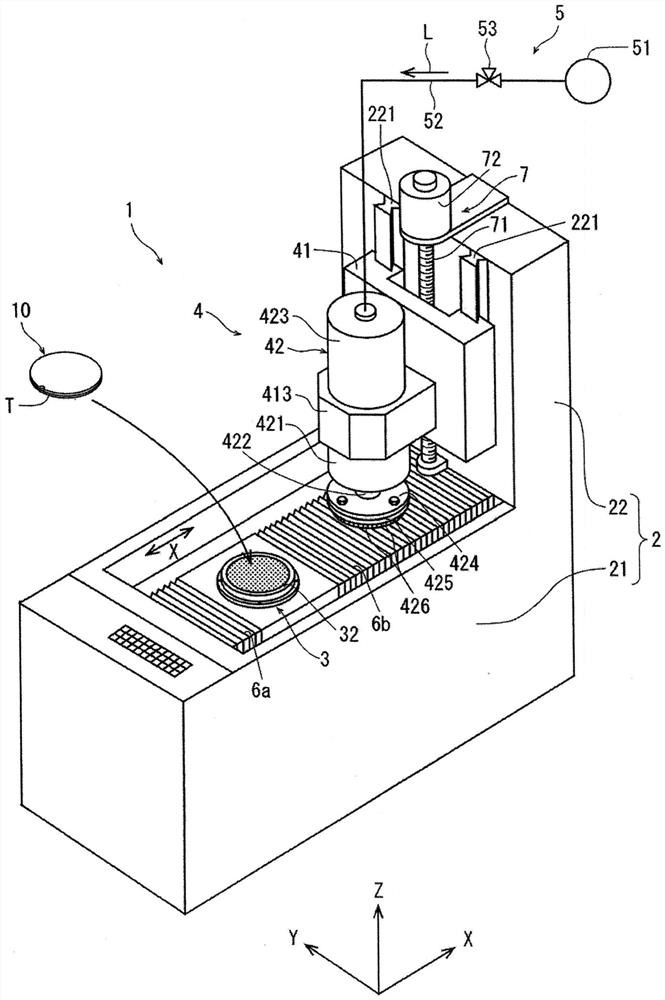

[0022] figure 1 An overall perspective view of a grinding device 1 as a processing device according to the present embodiment is shown. figure 1 The shown grinding device 1 has: a chuck table mechanism 3 as a holding unit for sucking and holding a plate-shaped semiconductor wafer (hereinafter simply referred to as a wafer) 10 as a workpiece of this embodiment; The grinding unit 4 grinds the wafer 10 held by the chuck table mechanism 3 ; and the processing liquid supply unit 5 supplies the processing liquid to the wafer 10 .

[0023] The grinding device 1 has a device housing 2 . The device case 2 has a substantially rectangular parallelepiped main body 21 and an upstanding wall 22 provided at the rear end of the main body 21 and vertically erected.

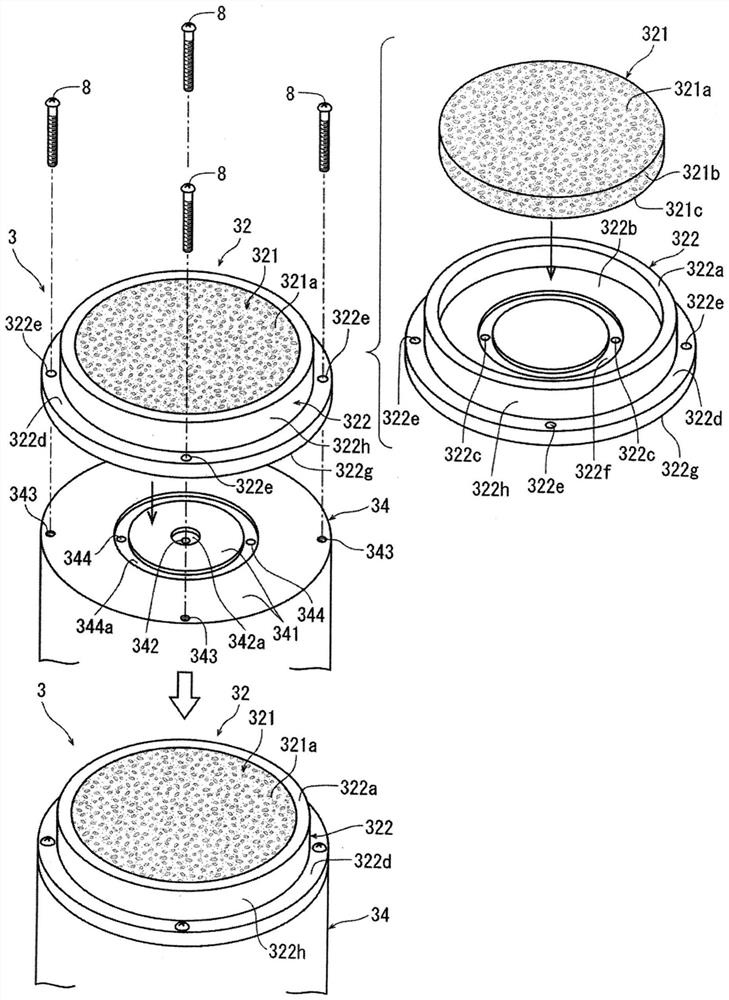

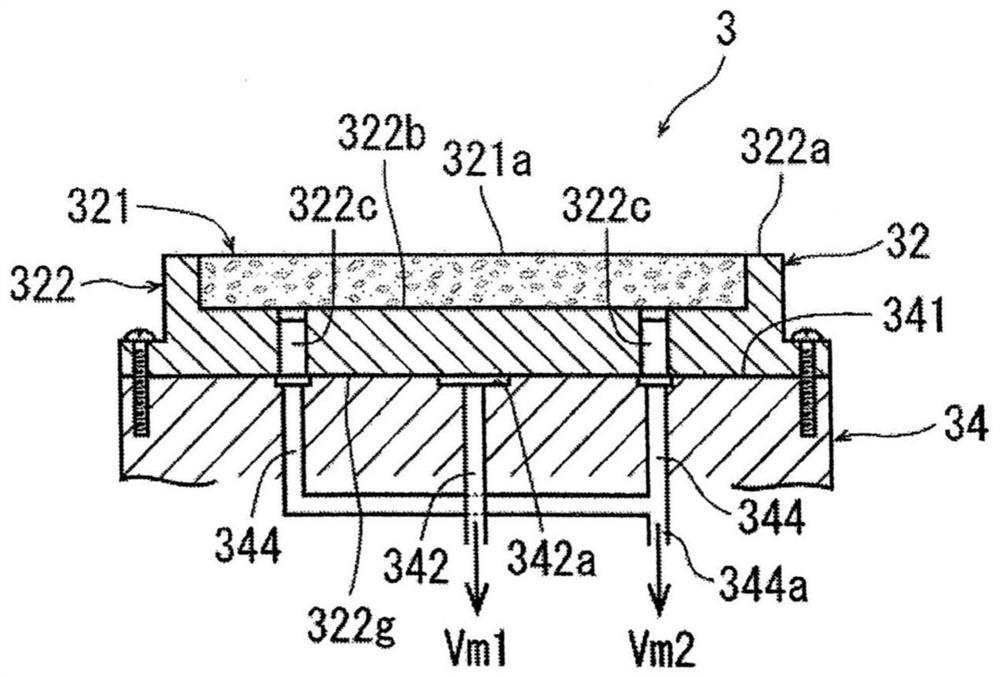

[0024] The chuck table mechanism 3 is disposed on the main body portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com