Method and device for making film by casting mould

A solution-based film-making and mold-making technology, which is applied in the direction of coating, etc., can solve the problems of cast coatings being easily affected by the outside world, production efficiency reduction, uneven thickness, etc., achieve excellent optical properties and physical properties, improve production efficiency, and durability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

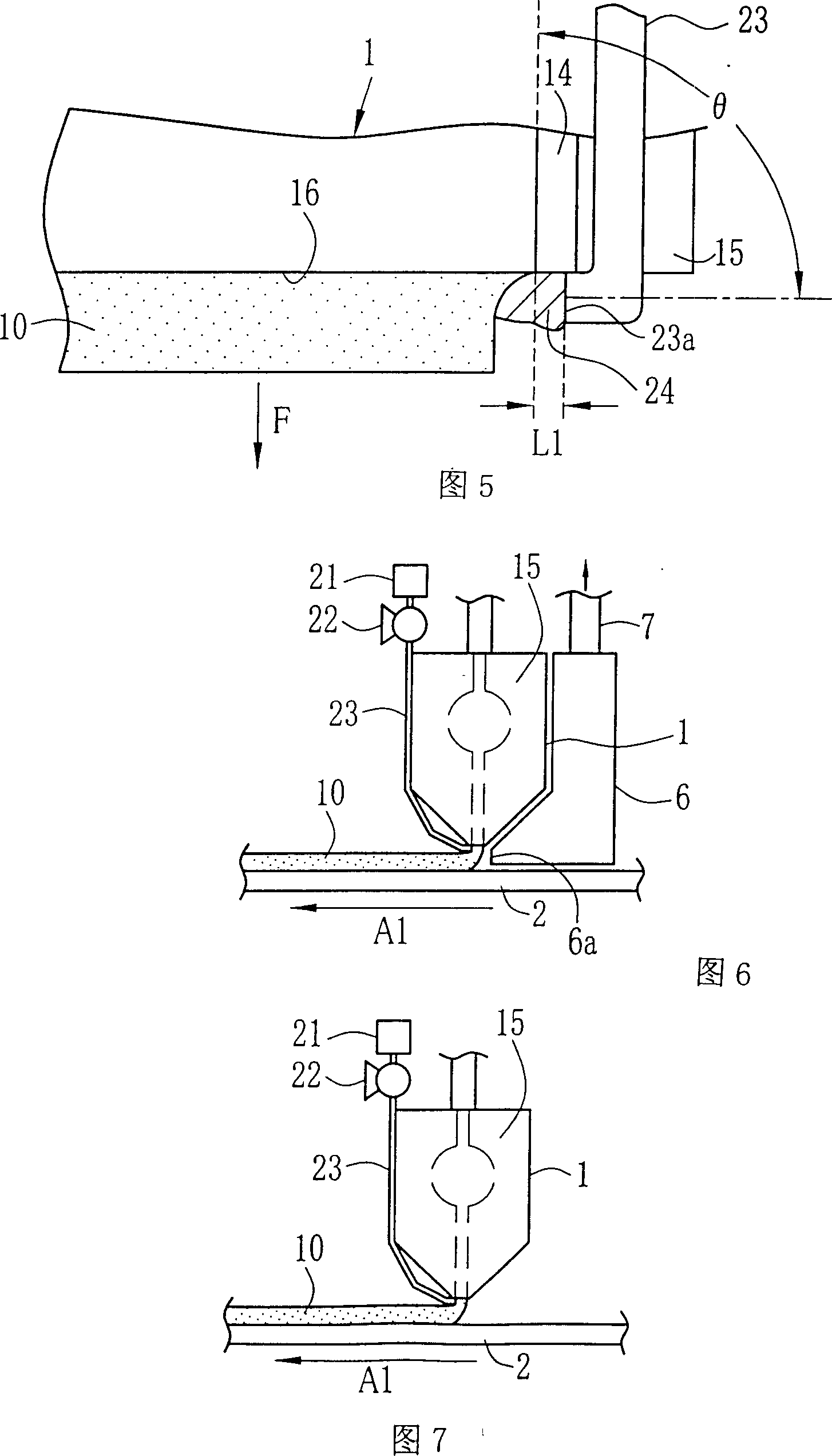

[0118] The monolayer continuous flow was performed under the following conditions. The conditions for supplying the solvent to the edge of the die cut are as follows.

[0119] 1) The flow rate is 0.2ml / min

[0120] 2) The inner diameter of the liquid supply nozzle is φ0.1 mm, the outer diameter is φ0.3 mm, and the discharge speed of the liquid supply nozzle is 42.5 cm / sec.

[0121] 3) The viscosity of the solvent is 0.5cp

[0122] 4) The surface tension of the solvent is 26dyn / cm

[0123] 5) The contact angle between the solvent and the front end of the liquid supply nozzle and the front end of the mold cutout is 30 degrees

[0124] 6) The distance L1 between the end of the continuous flowing paint and the front end of the liquid supply nozzle is 1.0mm

[0125] 7) The end of the flowing paint continues to be supplied from the die cutout along the horizontal direction

[0126] 8) Solvent composition Methylene chloride 60% by weight

[0127] Methanol 40% by weight

[0128...

Embodiment 2

[0131] The co-continuation flow is carried out under the following conditions. Conditions for supplying the solvent to the upper edge of the die cut are as follows.

[0132] 1) The flow rate is 0.2ml / min

[0133] 2) The inner diameter of the liquid supply nozzle is φ0.1mm, the outer diameter is φ0.3mm, and the discharge speed of the liquid supply nozzle is 42.5cm / s

[0134] 3) The viscosity of the solvent is 0.5cp

[0135] 4) The surface tension of the solvent is 26dyn / cm

[0136] 5) The contact angle between the solvent and the front end of the liquid supply nozzle and the front end of the mold cutout is 30 degrees

[0137] 6) The distance L1 between the end of the continuous flowing paint and the front end of the liquid supply nozzle is 1.0mm

[0138] 7) The end of the flowing paint continues to be supplied in the horizontal direction from the die cutout

[0139] 8) Solvent composition Methylene chloride 60% by weight

[0140] Methanol 40% by weight

[0141] 9) Nozzle...

Embodiment 3

[0144] The continuous flow of a single layer was carried out by the following paint formulation, and the conditions for supplying the solvent to the edge of the die cut were as follows.

[0145] 100 parts by weight of cellulose triacetate

[0146] 10 parts by weight of triphenyl phosphate

[0147] 5 parts by weight of biphenyl diphenyl phosphate

[0148] 315 parts by weight of methyl acetate

[0149] Methanol 60 parts by weight

[0150] 10 parts by weight of n-butanol

[0151] Swell the cellulose triacetate with a solvent for 30 minutes, then send the cellulose triethyl acetate solution out with a screw extruder, pass through the cooling zone, and keep at -70°C for 3 minutes. Cooling was performed using a refrigerant (Novac FC-77 or HFE-7100 manufactured by 3M Corporation) cooled to -80° C. with a refrigerator. The solution obtained by cooling was put into a stainless steel container, and stirred at 50° C. for 2 hours. Filtration was performed with filter paper (manufact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com