Automatic plastic cover UV screen printing device and screen printing method thereof

A screen printing device and plastic cover technology, applied in printing devices, screen printing, screen printing machines, etc., can solve the problems of high price, narrow use range, low work efficiency, etc., and achieve simple material management and reasonable structure design , Silk screen printing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

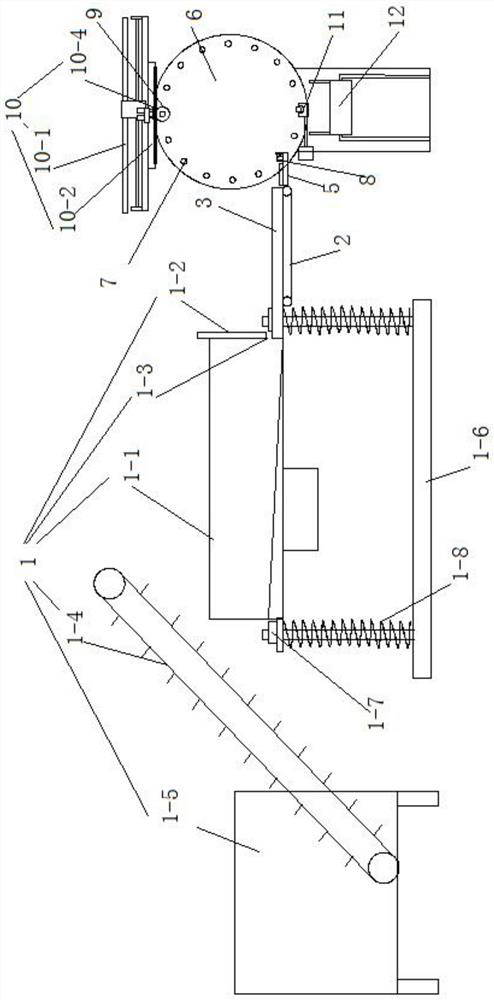

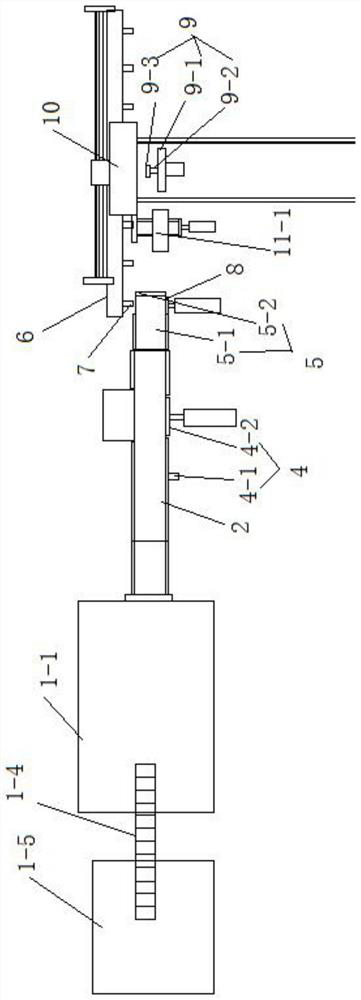

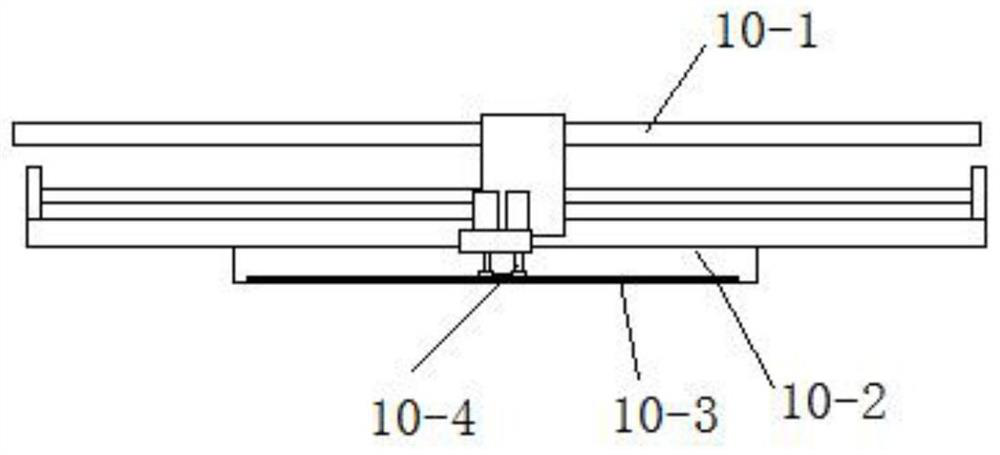

[0028] See attached picture.

[0029]An automatic UV screen printing device for plastic caps, including a feeding station, a cap arranging station, a silk screen printing station, and a discharging station arranged in sequence. The feeding station includes a vibration device for laying down and rolling the bottle cap The discharge assembly 1, the discharge end of the vibration discharge assembly 1 corresponds to the cover row station, the cover discharge station includes a feed cycle conveyor belt 2, and baffles 3 are provided on both sides of the feed cycle conveyor belt 2, The middle side of the material circulation conveyor belt 2 is erected with a cap kick assembly 4 for removing the opening of the bottle cap in the wrong direction, and a blanking table 5 is provided on the screen printing station corresponding to the end of the discharge end of the feed circulation conveyor belt 2. One side of the blanking table 5 is provided with a turntable 6, and fixed shafts 7 for fix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap