Fabric dipping mangle roller and after-finishing device

A technology for rolling liquid and fabrics, which is applied in the processing of textile materials, the configuration of equipment for processing textile materials, and the processing of liquid/gas/vapor fabrics. Enhance the effect of impregnation and stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

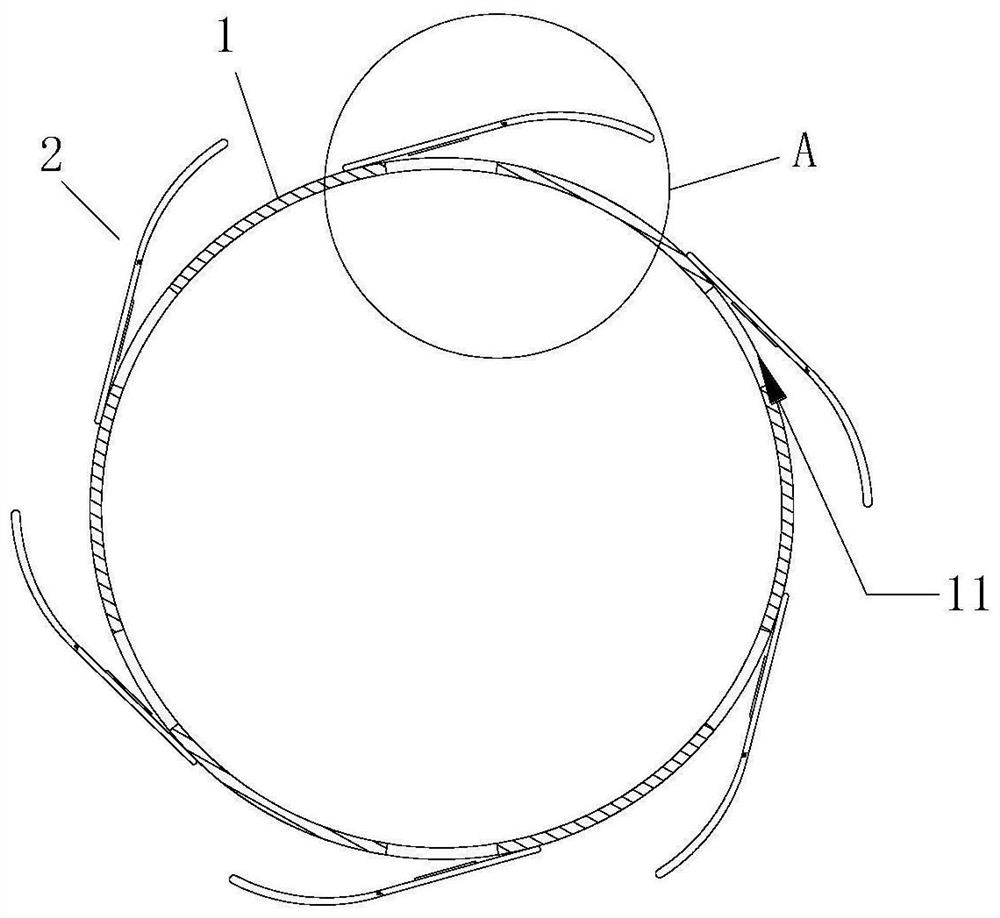

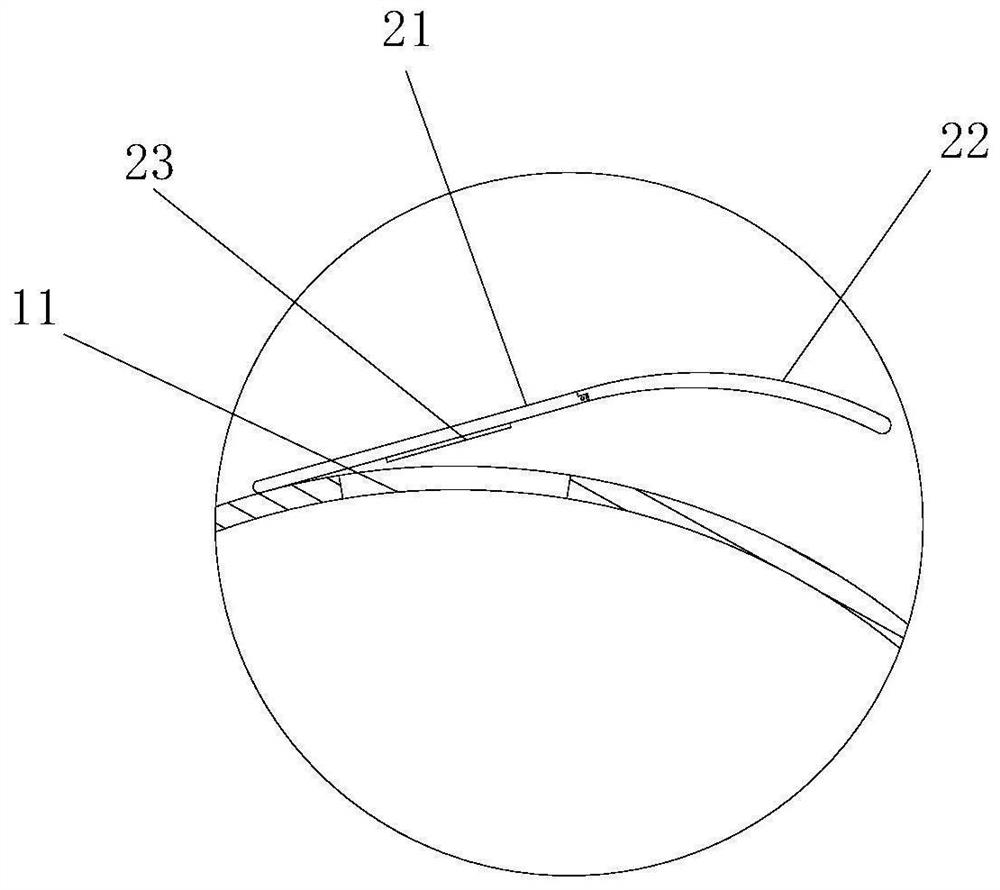

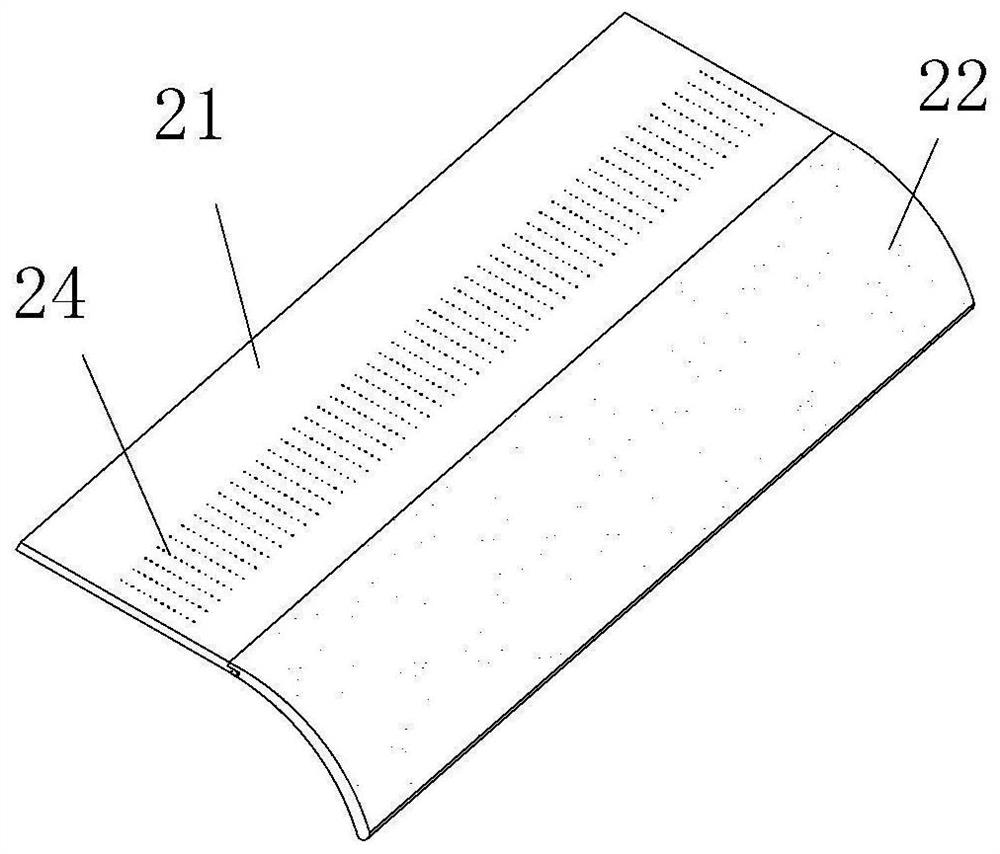

[0030] refer to Figure 1-2 , a fabric impregnated jipping roll, comprising a jipping roll 1, guide stirring plates 2 with openings arranged at equal intervals on the jipping roll 1, the guide stirring plate 2 and the jipping roll 1 The included angle is an acute angle (preferably less than 30°), and the guide stirring plate 2 includes a rotatable and self-resetting straight plate 21 and an arc-shaped plate 22, which facilitate non-rigid contact with the fabric during rotation and protect the fabric. Can play a stirring role.

[0031] In this embodiment, the rolling liquid roller 1 of the guiding stirring plate 2 is arranged tangentially, and the arc-shaped plate 22 is connected tangentially to the outer end side of the straight plate 21 .

[0032] In order to facilitate the collection of fluffy waste, the liquid squeezer 1 is hollow, and a through hole 21 is opened corresponding to the straight plate 21 . Because the angle between the straight plate 21 and the squeeze roll ...

Embodiment 2

[0039] Such as Figure 8 , in order to prevent the floating impurities washed into the inner side of the straight plate 22 from flowing out, a baffle plate attached to the surface of the squeeze roll 1 is fixed on the end side of the cardboard 21 .

Embodiment 3

[0041] refer to Figure 9 , a sorting device using the above-mentioned sorting rollers, comprising a sorting pool 3, at which two ends of the sorting pool 3 are provided with inlets and outlets for fabrics, and correspondingly provided with guide rollers 31 for guiding the fabrics in and out. The liquid rollers 1 are arranged at the same height and fit in the finishing tank 3, so that the rotation tracks of the adjacent liquid rollers 1 are attached or partially overlapped, and the fabric passes through the guide plate 2, and the adjacent liquid rollers The rotation direction of the roller 1 is opposite, and the guide mandrel 2 can interact to play the effect of extruding the fabric.

[0042] In addition, since the rotation directions of the adjacent squeeze rollers 1 are opposite, the stirring effect can be strengthened, so that the finishing liquid is mixed more evenly, and no additional stirring device is needed.

[0043] Of course, it should be noted that in this implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com