Fabricated enclosing wall structure

A prefabricated and wall-mounted technology, applied in the direction of fences, building types, buildings, etc., can solve the problems of air bubbles or repair marks, color difference on the concrete surface, difficult process control, etc., so as to reduce surface cracks and reduce wet work. , the effect of improving the overall sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

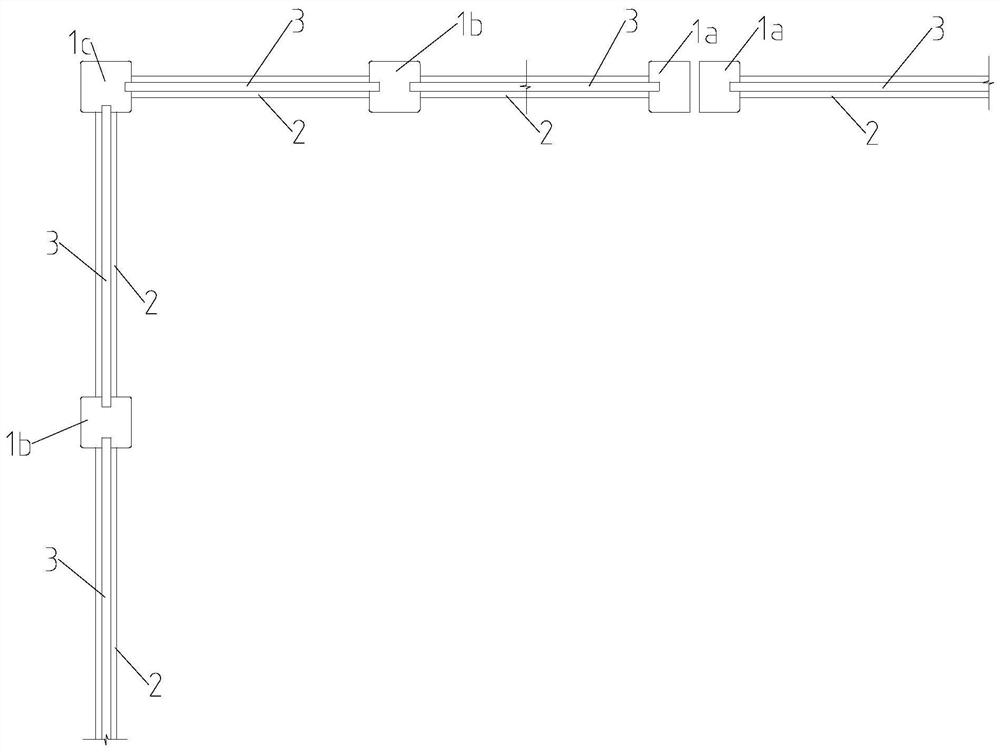

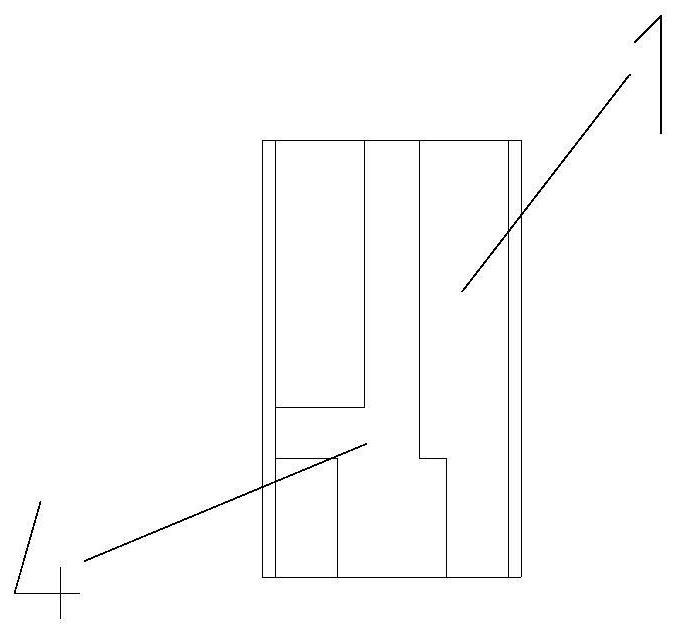

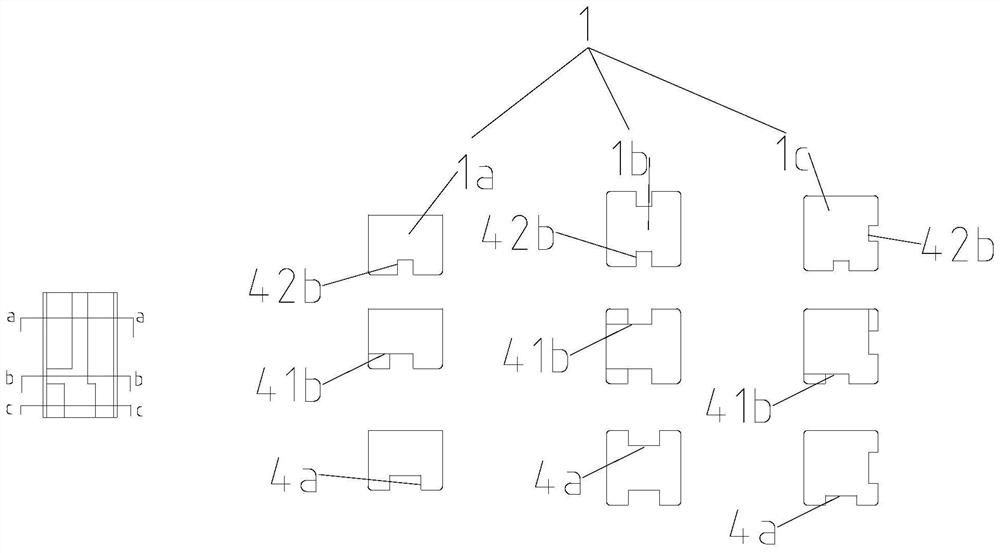

[0021] figure 1 It is a structural schematic diagram of an embodiment of the present invention, figure 2 It is a structural schematic diagram of the tenon and groove of the present invention, image 3 It is a cross-sectional structure schematic diagram of different cross-sectional positions of each base column in the present invention, Figure 4 It is a structural schematic diagram of the connection between the base column and the connecting beam and the coaming plate of the present invention, Figure 5 It is a schematic diagram of the cross-sectional structure of the connecting beam of the present invention, Figure 6 It is a schematic diagram of the cross-sectional structure of the coaming of the present invention. As shown in the figure, the assembled wall structure in this embodiment includes a base column 1, a connecting beam 2 and a coaming plate 3, and the lower end of the base column 1 is fixedly embedded in the foundation , the connecting beam 2 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com