Stress strain temperature measuring cable and manufacturing method thereof

A technology of stress-strain and temperature measurement, which is applied in the direction of fluid pressure measurement, measurement device, and measurement of fluid pressure using optical methods. The effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

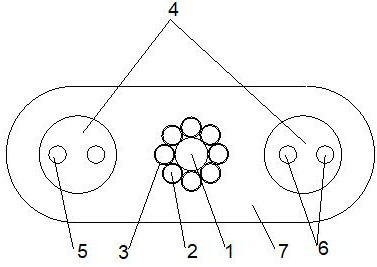

[0031] Stress and strain temperature measurement cable, including single-mode optical fiber 5, tight-wrapped optical fiber 1 and multi-mode optical fiber 6, single-mode optical fiber 5 and multi-mode optical fiber 6 are respectively provided with threaded loose sleeve steel pipe 4, and tight-wrapped optical fiber 1 is provided with G- FRP armor reinforcement 2, G-FRP armor reinforcement 2 are equipped with EVA3 on both sides, threaded loose sleeve steel pipe 4 and G-FRP armor reinforcement 2 is extruded with semi-conductive PE sheath 7.

[0032] Tight-wrapped fiber 1 is connected with G-FRP armor reinforcement 2 through EVA3, and semi-conductive PE sheath 7 is connected with G-FRP armor reinforcement 2 through EVA3. The outer diameter of the long, tight-packed optical fiber 1 is 0.45 mm.

[0033] The G-FRP armor reinforcement 2 is twisted on the periphery of the tight-packed optical fiber 1 in a unidirectional "S" shape. The outer diameter of the G-FRP armor reinforcement 2 is...

Embodiment 2

[0043] Stress and strain temperature measurement cable, including single-mode optical fiber 5, tight-wrapped optical fiber 1 and multi-mode optical fiber 6, single-mode optical fiber 5 and multi-mode optical fiber 6 are respectively provided with threaded loose sleeve steel pipe 4, and tight-wrapped optical fiber 1 is provided with G- FRP armor reinforcement 2, G-FRP armor reinforcement 2 are equipped with EVA3 on both sides, threaded loose sleeve steel pipe 4 and G-FRP armor reinforcement 2 is extruded with semi-conductive PE sheath 7.

[0044] Tight-wrapped fiber 1 is connected with G-FRP armor reinforcement 2 through EVA3, and semi-conductive PE sheath 7 is connected with G-FRP armor reinforcement 2 through EVA3. The outer diameter of the long, tight-packed optical fiber 1 is 0.4 mm.

[0045]The G-FRP armor reinforcement 2 is twisted in a unidirectional "S" on the periphery of the tight-packed optical fiber 1. The outer diameter of the G-FRP armor reinforcement 2 is 0.35mm,...

Embodiment 3

[0055] Stress and strain temperature measurement cable, including single-mode optical fiber 5, tight-wrapped optical fiber 1 and multi-mode optical fiber 6, single-mode optical fiber 5 and multi-mode optical fiber 6 are respectively provided with threaded loose sleeve steel pipe 4, and tight-wrapped optical fiber 1 is provided with G- FRP armor reinforcement 2, G-FRP armor reinforcement 2 are equipped with EVA3 on both sides, threaded loose sleeve steel pipe 4 and G-FRP armor reinforcement 2 is extruded with semi-conductive PE sheath 7.

[0056] Tight-wrapped fiber 1 is connected with G-FRP armor reinforcement 2 through EVA3, and semi-conductive PE sheath 7 is connected with G-FRP armor reinforcement 2 through EVA3. The outer diameter of the long, tight-packed optical fiber 1 is 0.5 mm.

[0057] The G-FRP armor reinforcement 2 is twisted in a unidirectional "S" on the periphery of the tight-packed optical fiber 1. The outer diameter of the G-FRP armor reinforcement 2 is 0.45mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com