Welding process quality online analysis system and method based on cloud server

A welding process and cloud server technology, which is applied in the direction of material analysis, analysis of materials, and instruments by electromagnetic means, can solve the problems of inability to effectively monitor welding quality and low speed of welding process information collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

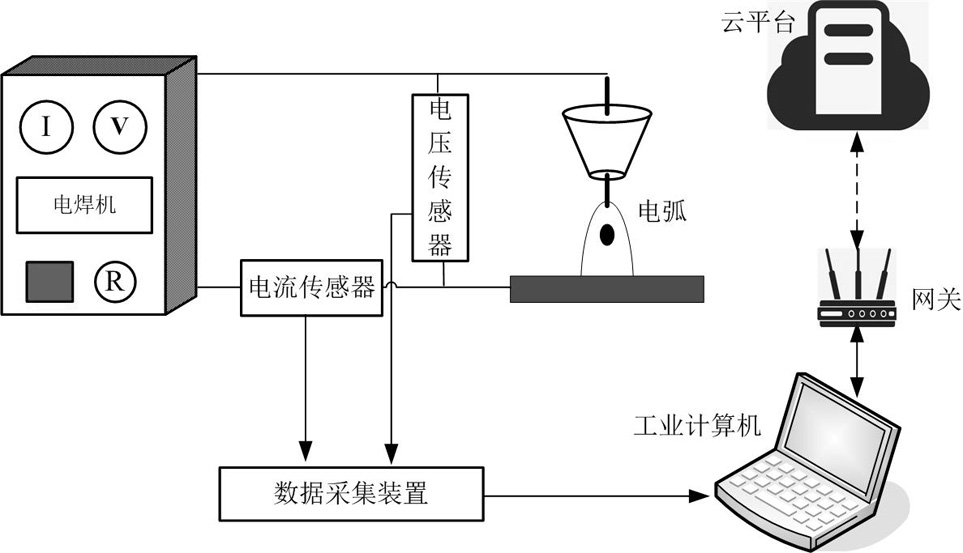

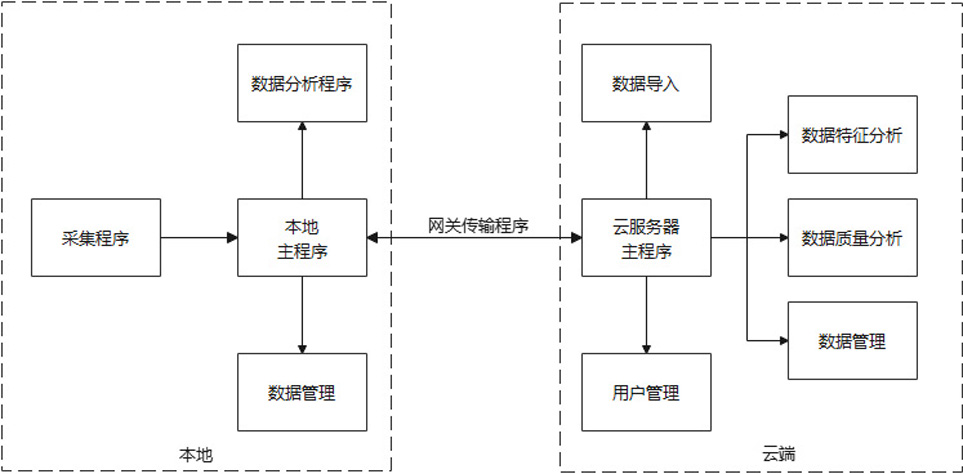

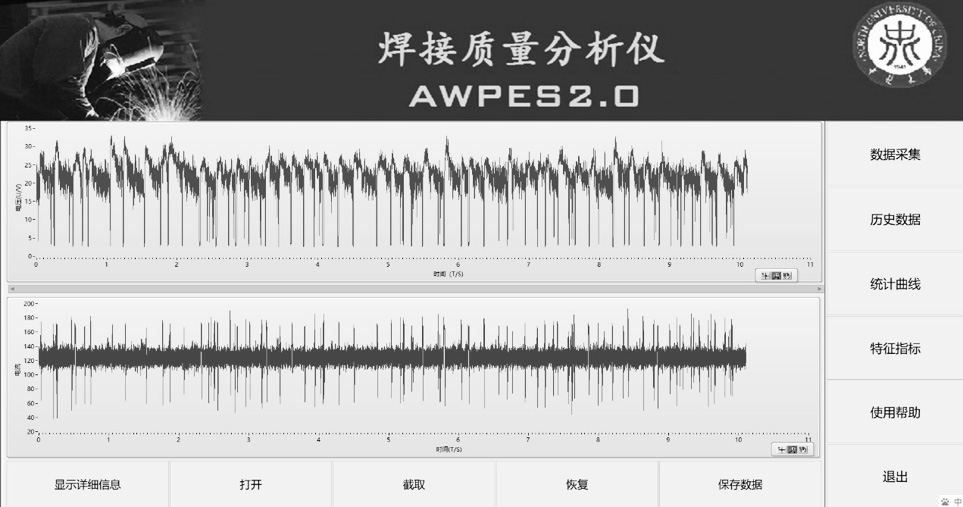

[0065] Embodiment 1: In this example, the user uses the local end system to analyze the quality of the welding process. see figure 1 As shown, the current sensor and voltage sensor are connected to the electric welding machine, the sensors are connected to the data acquisition device, the acquisition device is connected to the computer for communication, and the computer communicates wirelessly with the cloud platform through the gateway. Power on all hardware and start the system, put the whole system in standby state. The welding operation is performed, and the system starts to collect current and voltage signals during the welding process. The collected data is sent to the computer by the data acquisition device, such as image 3 As shown, the computer stores and displays the collected data; such as Figure 4 As shown, the software further analyzes the collected data to obtain the characteristic indicators of the welding process.

Embodiment 2

[0066] Embodiment 2: In this example, the user uses the cloud system to analyze the quality of the welding process. First connect the acquisition device to the welding machine, see figure 1 shown. Start the system and put the whole system in standby state. The system starts to collect and perform welding operations at the same time, and collects current and voltage signals during the welding process. The data collected by the data acquisition device is sent to the computer, and the computer uploads to the designated cloud server through the gateway. After the cloud server receives the data, it calculates the characteristic indicators of the welding process, such as Figure 5 , the statistical analysis results are displayed graphically as Figure 6 , users can view the analysis results through multiple terminals.

Embodiment 3

[0067] Embodiment 3: This example uses the system of the present invention to analyze the welding process quality of argon tungsten arc welding. Such as Figure 7 As shown, the user collects the welding process voltage and current information of argon tungsten arc welding in real time, and uploads the data to the cloud platform. If the argon arc welding data is within the standard signal range, it is judged that the welding quality is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com