Insulating film for transformer coil and preparation method of insulating film

A technology of transformer coils and insulating films, applied in the field of transformers, can solve the problems of the strength of insulating resin layers, poor corrosion resistance, working temperature difference, inability to meet the high power output of transformers, etc., and achieves good corrosion resistance, good weather resistance, and high ceramic hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

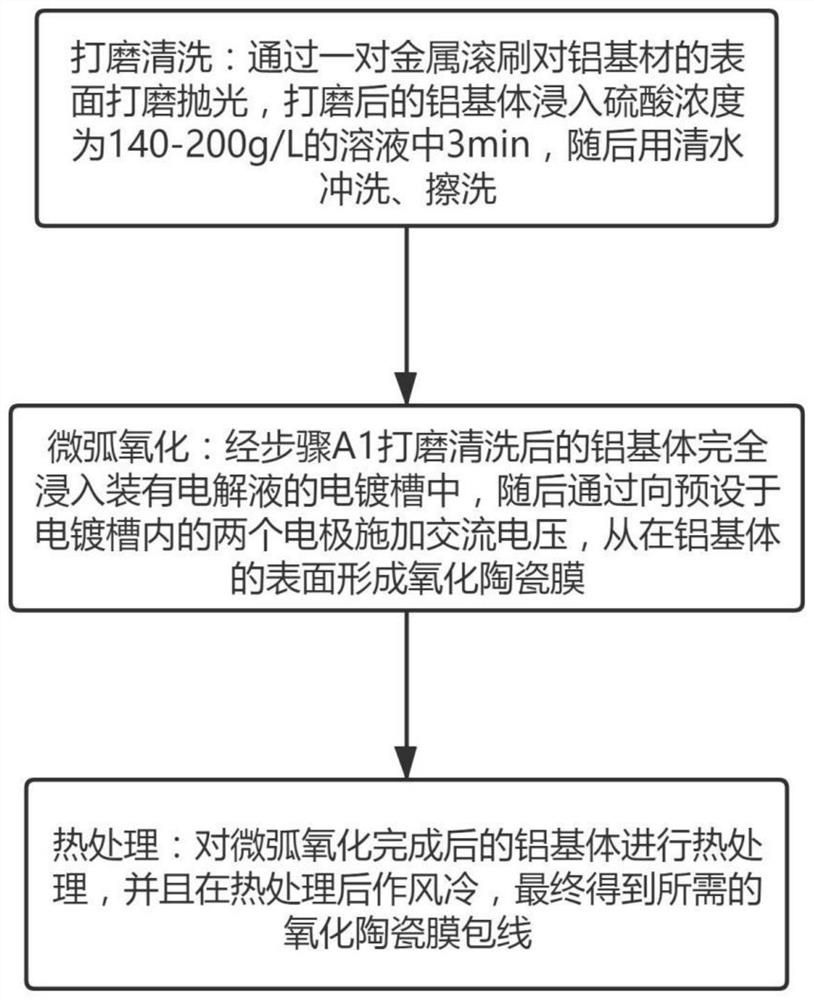

[0057] This embodiment 1 provides the first method for preparing an insulating film of a transformer coil, comprising the following steps:

[0058] Step S0, grinding and cleaning: Grinding and polishing the surface of the aluminum substrate with a pair of metal roller brushes, immersing the polished aluminum substrate in a solution with a sulfuric acid concentration of 140-200g / L for 3 minutes, and then rinsing and scrubbing with clean water to clean the surface In addition, the surface of the ground and polished aluminum substrate is smooth and flat.

[0059] Step S1, micro-arc oxidation: the polished and cleaned aluminum substrate in step S0 is completely immersed in an electroplating tank filled with electrolyte.

[0060] Step S2, by applying an AC voltage to the two electrodes preset in the electroplating tank, making them alternately serve as anodes and cathodes, so that an alumina ceramic layer is formed on the surface of the aluminum substrate immersed in the electrolyt...

Embodiment 2

[0069] This embodiment 2 is to detect the hardness, friction coefficient, breakdown voltage, corrosion resistance and heat transfer coefficient of the insulation film of the transformer coil prepared in embodiment 1; also detect the traditional resin transformer with only an insulating resin layer on the surface of the transformer coil The weight, operating temperature, and energy efficiency of the transformer whose surface is the insulating film of the transformer coil prepared in Example 1 are shown in Table 1 and Table 2.

[0070] It can be seen from Table 1 that the hardness, friction coefficient, breakdown voltage, corrosion resistance and heat transfer coefficient of the insulation film of the transformer coil prepared in Example 1 are excellent, and can meet the requirements of the high power output of the transformer, such as strength, corrosion resistance, and workability. temperature difference requirements;

[0071] As can be seen from Table 2, the weight, operating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com