A high-efficiency cleaning device for internally threaded copper pipes

A cleaning device and internal thread technology, which is applied in the field of high-efficiency cleaning devices for internal thread copper pipes, can solve the problems of moisture in the inner wall of copper pipes, easy corrosion and oxidation, and copper shavings that cannot be washed away, so as to save space and avoid mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

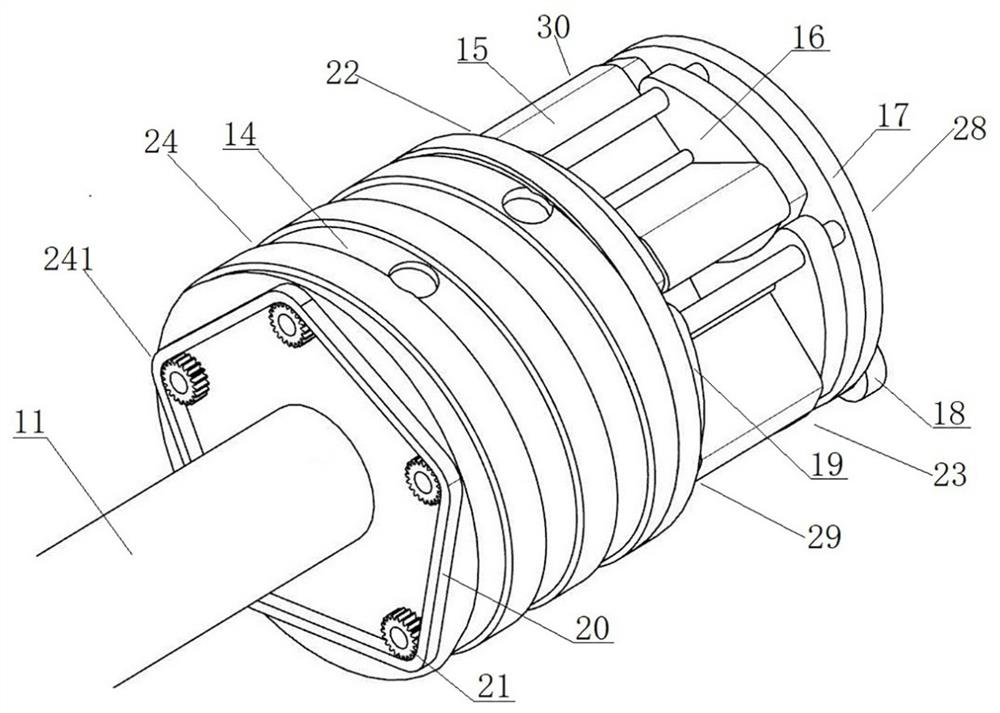

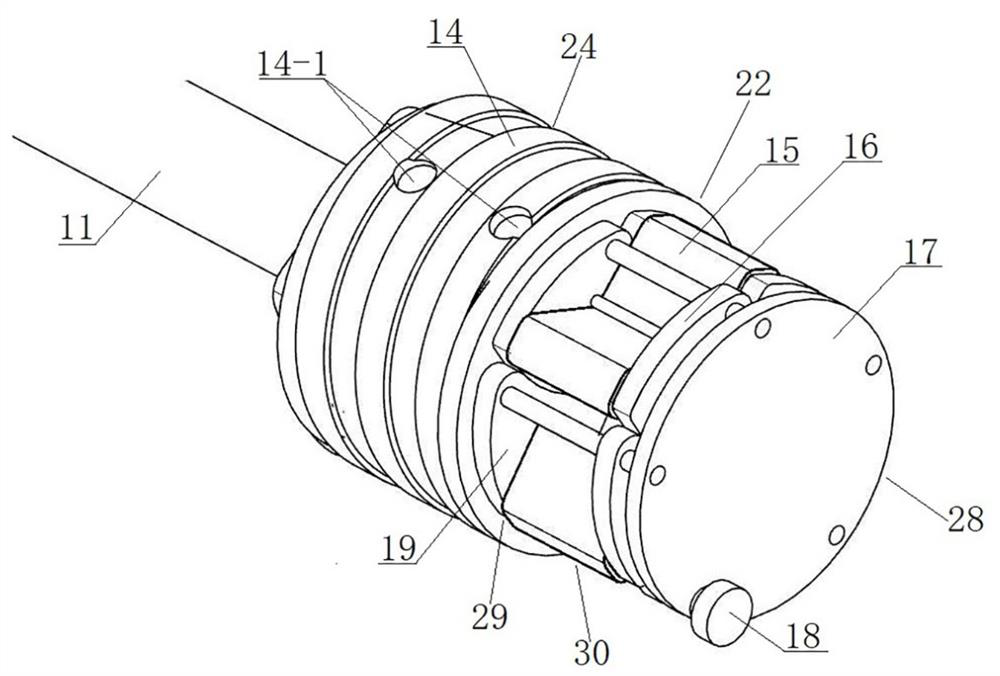

[0042] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

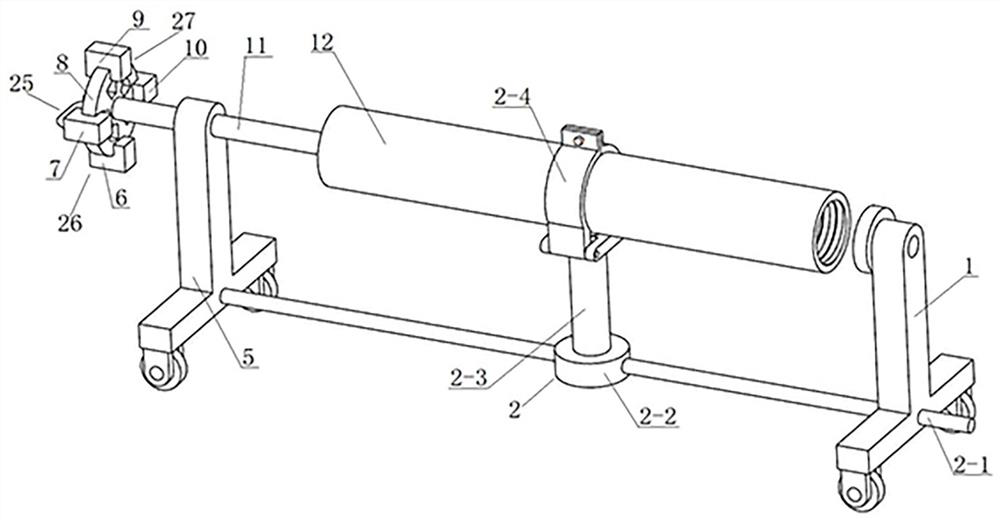

[0043] see figure 1 , a high-efficiency cleaning device for internally threaded copper pipes, comprising a supporting rotating base 2, a mobile frame 1 and a fixed frame 5 respectively arranged on both sides of the supporting rotating base 2, a cleaning system 22 arranged on the fixing frame 5, and a supporting rotating base 2 A copper pipe 12 is arranged on the upper level, and the moving frame 1 is detachably connected to one end of the copper pipe 12 , and the cleaning system 22 is movably arranged in the copper pipe 12 .

[0044]More preferably, the supporting rotating seat 2 includes a positioning seat 2-2, a rotating column 2-3 vertically arranged on the positioning seat 2-2, and the top of the rotating column 2-3 is provided with a fastening snap ring 2-4, copper The pipe 12 is clamped in the fastening snap rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com