Pretreatment strengthening method of recycled aggregate and preparation method of recycled concrete

A technology of recycled concrete and recycled aggregate is applied in the preparation of recycled concrete and the field of pretreatment and strengthening of recycled aggregate. , the effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

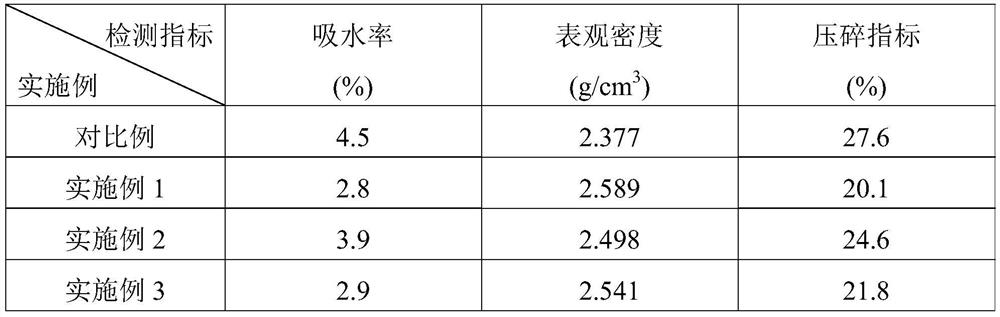

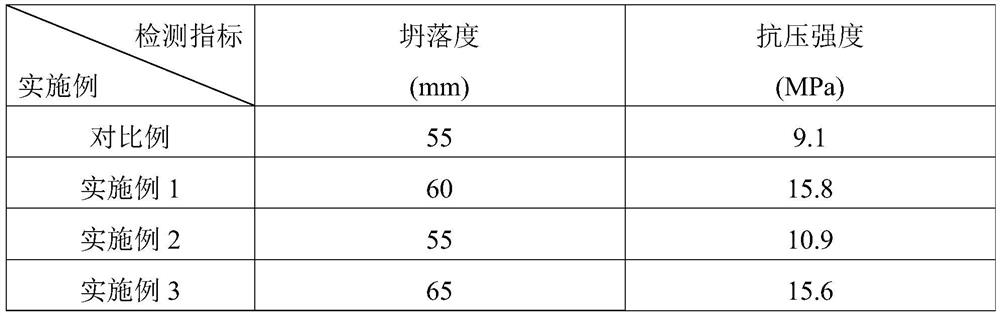

Embodiment 1

[0048] A pretreatment strengthening method for recycled aggregates, comprising the following steps:

[0049] 1) Classifying, crushing, sorting and screening waste concrete to obtain 50 kg of recycled aggregate with a particle size of (5-25) mm;

[0050] 2) Rinse the recycled aggregate with low-pressure water for 6 minutes, collect the washing liquid, and dry the rinsed recycled aggregate naturally at 18°C to obtain dry recycled aggregate;

[0051] 3) Ca(OH) 2 Add it into water and stir evenly, then add polyvinyl alcohol solution and stir to get Ca(OH) 2 An aggregate strengthening solution with a mass content of 10% and a polyvinyl alcohol content of 8%;

[0052] 4) Immerse 4kg of dry recycled aggregate in 40kg of aggregate strengthening solution for 12 hours, take it out and then dry it naturally at 18°C, and obtain strengthened recycled aggregate with a particle size of (5-25)mm after sieving.

Embodiment 2

[0054] The Ca(OH) of the aggregate strengthening solution used in this example 2 The mass content is 8%, the polyvinyl alcohol mass content is 8%, soaked for 6 hours, and then dried naturally at 25°C after taking it out, and the rest is the same as that of Example 1.

Embodiment 3

[0056] The Ca(OH) of the aggregate strengthening solution used in this example 2 The mass content is 12%, the polyvinyl alcohol mass content is 6%, soaked for 8 hours, and then dried naturally at 20°C after taking it out, and the rest is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com