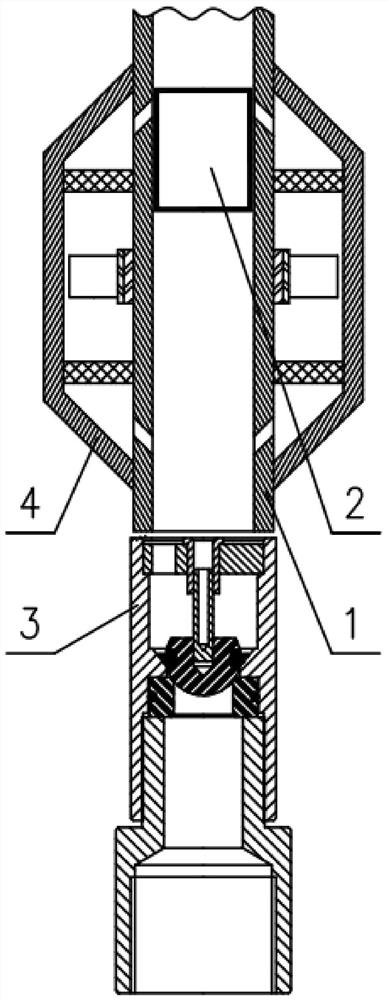

Tubing pump

An oil well pump and tube type technology, applied in the field of tube type oil well pump, can solve the problems of low pump efficiency and loss of oil and crude oil liquid in the tube type well well pump, and achieve the effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

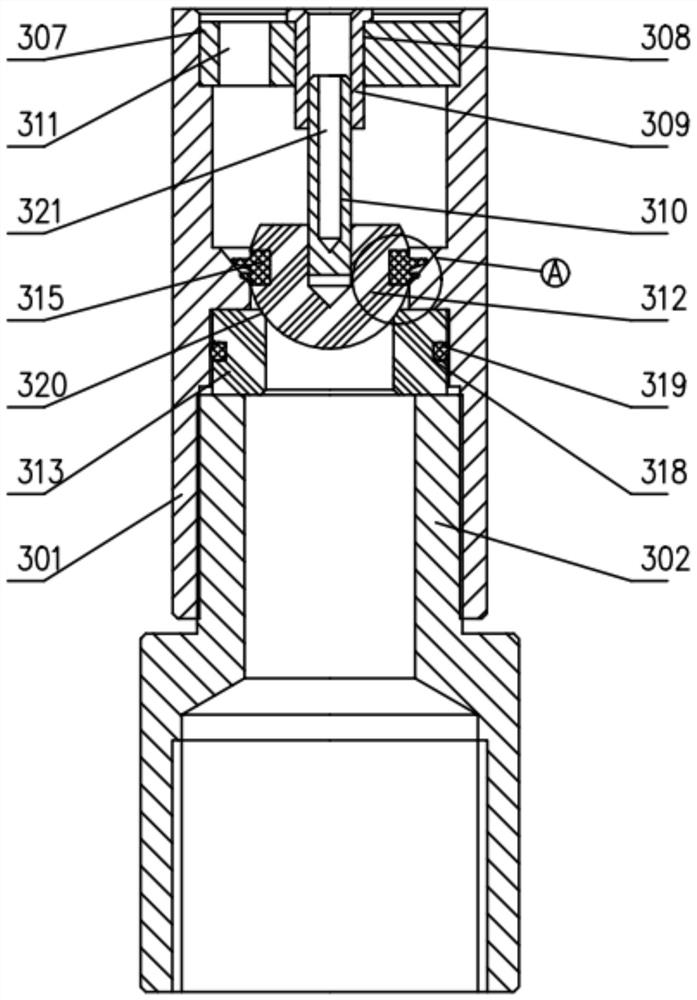

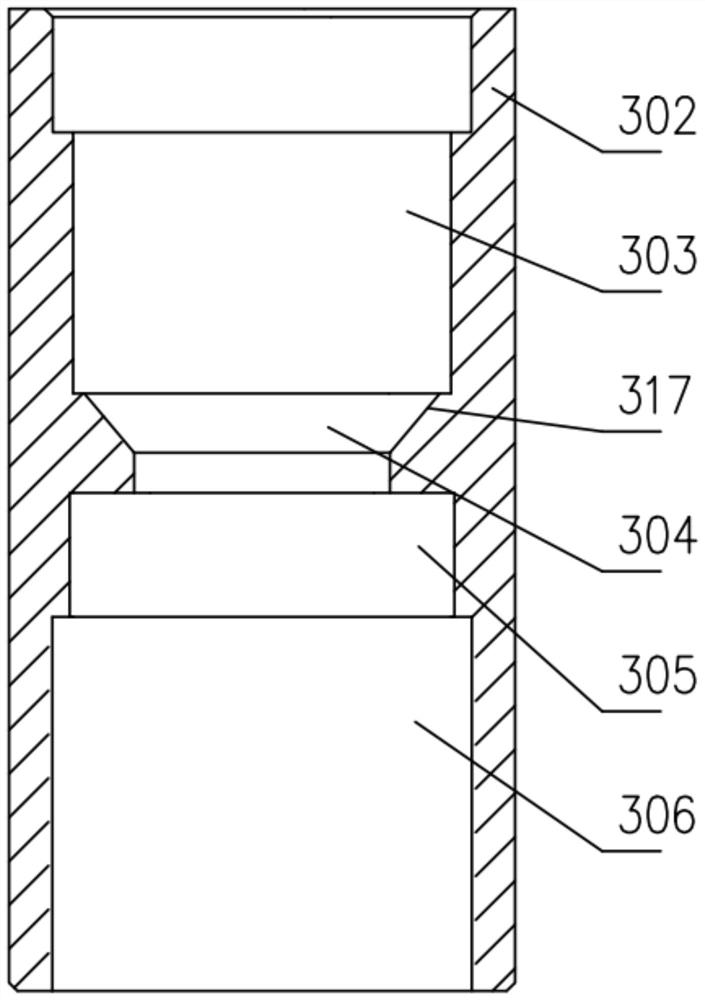

[0044] When the present invention is used, when the oil well pump is pressed down by the downstroke piston, due to the gravity falling of the crude oil and the downstroke pressure of the piston, a downward pressure is formed in the blind hole, which provides downward movement for the valve ball and closes the valve port. Power increases the closing speed of the valve ball; and because the positioning shaft at the upper end of the valve ball can only slide back and forth in the sleeve, the restricted valve ball can only open and close at the valve port up and down, the return time is short, and the return accuracy is high. Therefore, when the downstroke piston is pressed down, the valve ball returns to the closed position quickly and accurately. At this time, since the sealing sleeve is provided with an inner concave fillet with the same radian as the ball valve, a rigid seal of the ball valve is completed, and then through The diameter of the ball valve and the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com