Real-time monitoring device and method for surface salt settling volume

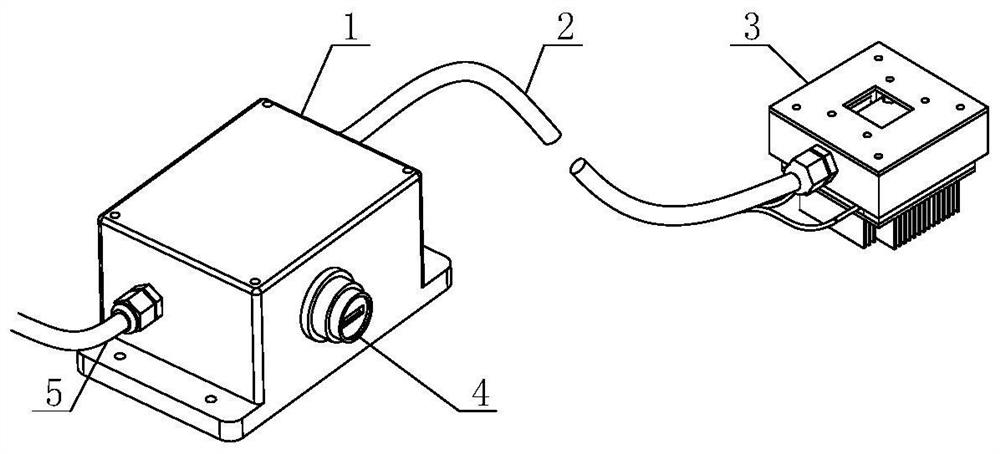

A technology of real-time monitoring and settlement, applied in the direction of material impedance, etc., can solve the problems of poor timeliness of measurement method results, and achieve the effects of shortening measurement time, ensuring timeliness, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

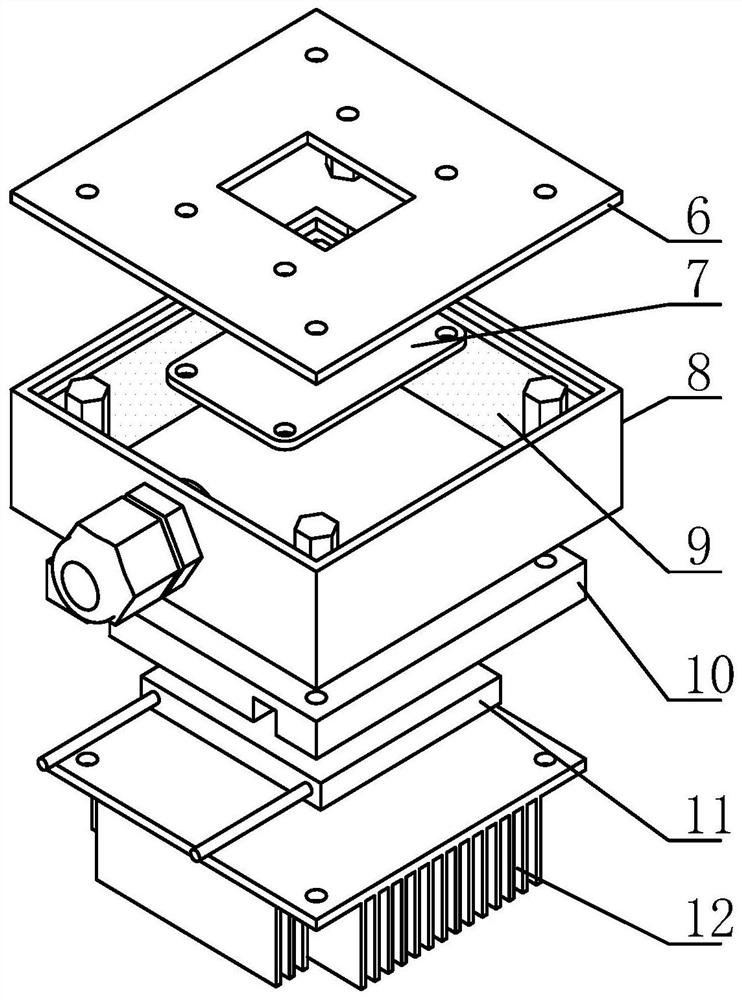

[0042] In this embodiment, the width of the fingers is 50 μm, and the distance between adjacent fingers is 50 μm.

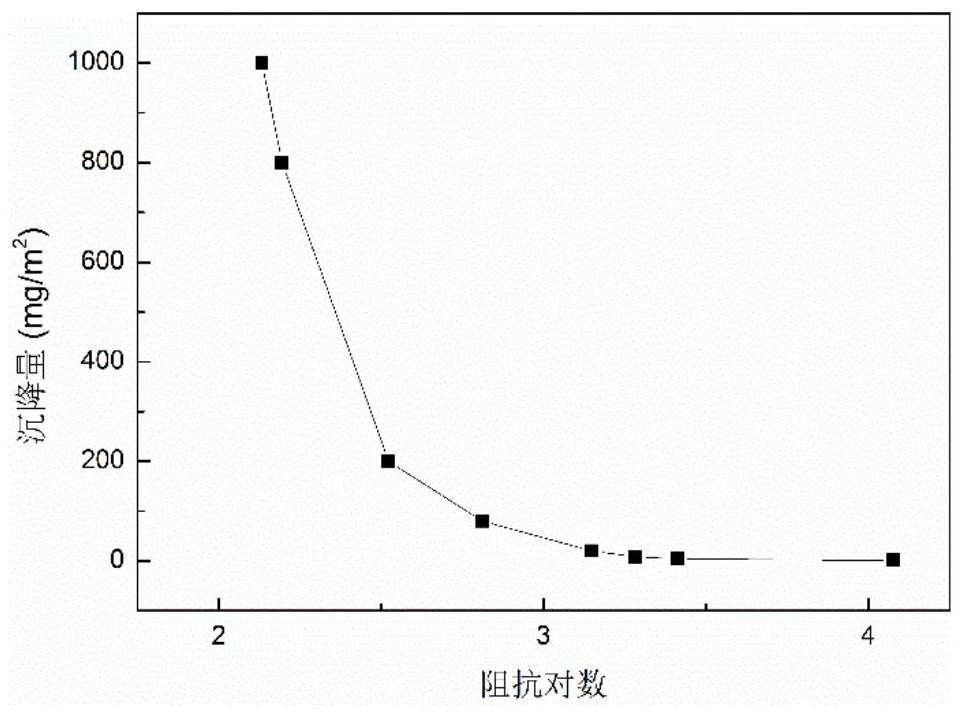

[0043] The first step is to draw the relationship curve between the amount of salt precipitation and the impedance value; the precipitation on the surface of the interdigitated electrode 7 of the monitoring probe 3 is 1mg / m 2 NaCl, and put the probe in an environment with a relative humidity of 80%. After placing it for 10 minutes, the salt deposited on the surface of the interdigital electrode 7 absorbs moisture to form a liquid film. The host 1 of the monitoring device generates a 10kHz fixed-frequency AC excitation signal through the transmission wire. 2. Pass to the interdigital electrode 7 of the monitoring probe 3, and analyze the received feedback signal to obtain the impedance value of the liquid film on the interdigital electrode 7 surface; change the NaCl settlement on the interdigital electrode 7 surface of the monitoring probe 3 to 4 , 8, 20, 80, 200,...

Embodiment 2

[0047] In this embodiment, the drawing of the corresponding relationship between the salt deposition amount and the measured impedance value in the first step is shown in Embodiment 1.

[0048] In the second step, the monitoring equipment is placed in the marine atmosphere environment for 7 days, and continuous measurement is performed. The impedance monitoring frequency of the equipment is 1 hour, and the power of the cooling plate 11 is controlled during the measurement. When the relative humidity measured by the temperature and humidity sensor is stable at 80 %, measure the impedance value of the liquid film on the surface of the interdigital electrode 7, and obtain the surface salt deposition amount according to the relationship curve between the salt deposition amount and the impedance value, and finally measure the surface salt deposition amount as Figure 4 shown.

[0049] In addition, if it is to be used for a long time in an environment with relatively high salt depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com