Pruning device for ultrahigh branches below power transmission line

A technology of pruning device and power transmission line, which is applied to electric pruning saws, botanical equipment and methods, agricultural machinery and implements, etc. Trimming efficiency, extended overhaul time, reduced job hazard effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

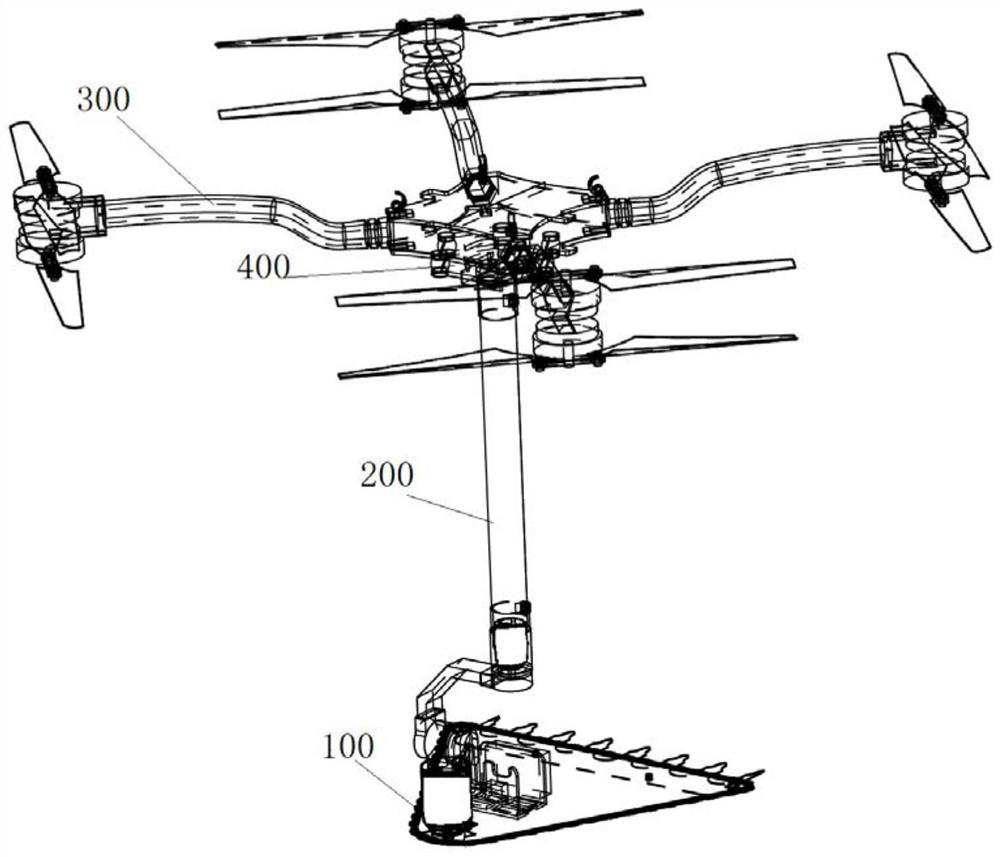

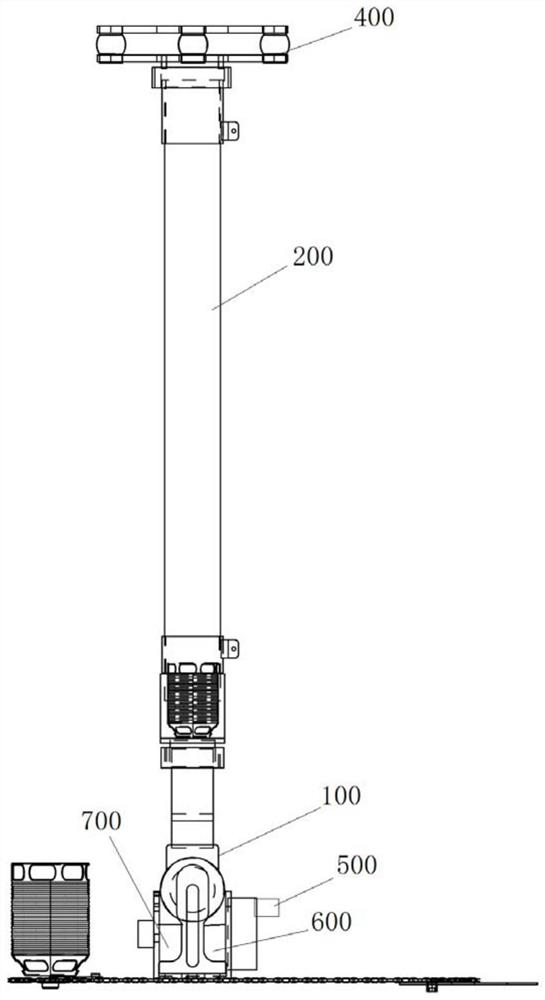

[0072] figure 1 shows a schematic diagram of a pruning device according to one embodiment of the invention; figure 2 A schematic diagram of a pruning device without a drone according to an embodiment of the present invention is shown.

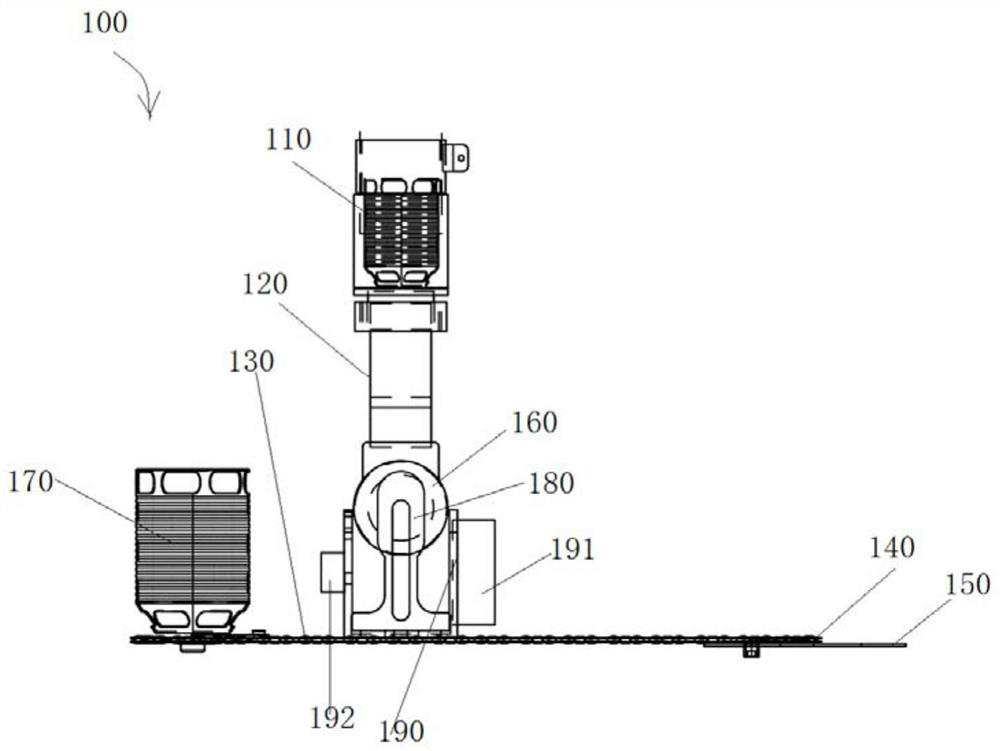

[0073] Such as figure 1 and figure 2 As shown, the present embodiment provides a pruning device for super-high branches below the power transmission line. The shearing device includes an unmanned aerial vehicle 300, a support rod 200, and a tree-cutting mechanism 100 arranged in sequence from top to bottom. The tree-cutting mechanism 100 includes :

[0074] The first power source 110 is arranged at the lower end of the support rod 200;

[0075] L-shaped connecting plate 120, one end of the L-shaped connecting plate 120 is connected to the rotating shaft of the first power source 110, and the other end of the L-shaped connecting plate 120 is fixedly connected to the second power source 160;

[0076] The tree felling plate assembly 130 inc...

Embodiment 2

[0084] Figure 3a Shows a front view of a tree felling mechanism according to an embodiment of the present invention; Figure 3b Shows the left side view of the felling mechanism according to one embodiment of the present invention; Figure 4 A schematic diagram of a felling board assembly according to one embodiment of the invention is shown.

[0085] Such as Figure 3a , Figure 3b and Figure 4 Shown, on the basis of embodiment 1, felling tree upper plate 131 and felling tree lower plate 132 are polygonal, a driving gear 133 is set at one corner of the polygon, and driven gear 134 is set at other corners of the polygon.

[0086] The driving gear 133 is set at one corner of the polygon, and the driven gear 134 is set at the other corners of the polygon, which can ensure that the working side of the chain saw 140 is located outside the felling board assembly 130, so that the chain saw 140 can cut super high branches.

[0087] In the present embodiment, the upper board 131 ...

Embodiment 3

[0102] Figure 5 A schematic diagram showing a felling board assembly for removing the upper board for felling trees according to an embodiment of the present invention.

[0103] Such as Figure 5 As shown, on the basis of Embodiment 2, a fixed rod 135 is provided between the upper board 131 and the lower board 132 for cutting down trees, the driven gear 134 is covered on the fixed rod 135, and the driven gear 134 and the fixed rod 135 pass through Bearing connection.

[0104] Only the third power source 170 is used to connect the tree-cutting upper plate 131 and the tree-cutting lower plate 132, which may easily cause the falling of the tree-cutting lower plate 132. By setting the fixing rod 135, the tree-cutting upper plate 131 and the tree-cutting lower plate 132 are reinforced. The connection between them improves the working stability of the felling board assembly 130.

[0105] Further, the felling board assembly 130 also includes a U-shaped bar groove 136, which is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com