Water-based sprinkling silk printing gloss oil ink and preparation method thereof

A water-based, fan-based technology, applied in ink, household utensils, applications, etc., can solve the problems of general adhesion, high human irritation, poor powder adhesion, etc., and achieve excellent powder performance, good flash, and adhesion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

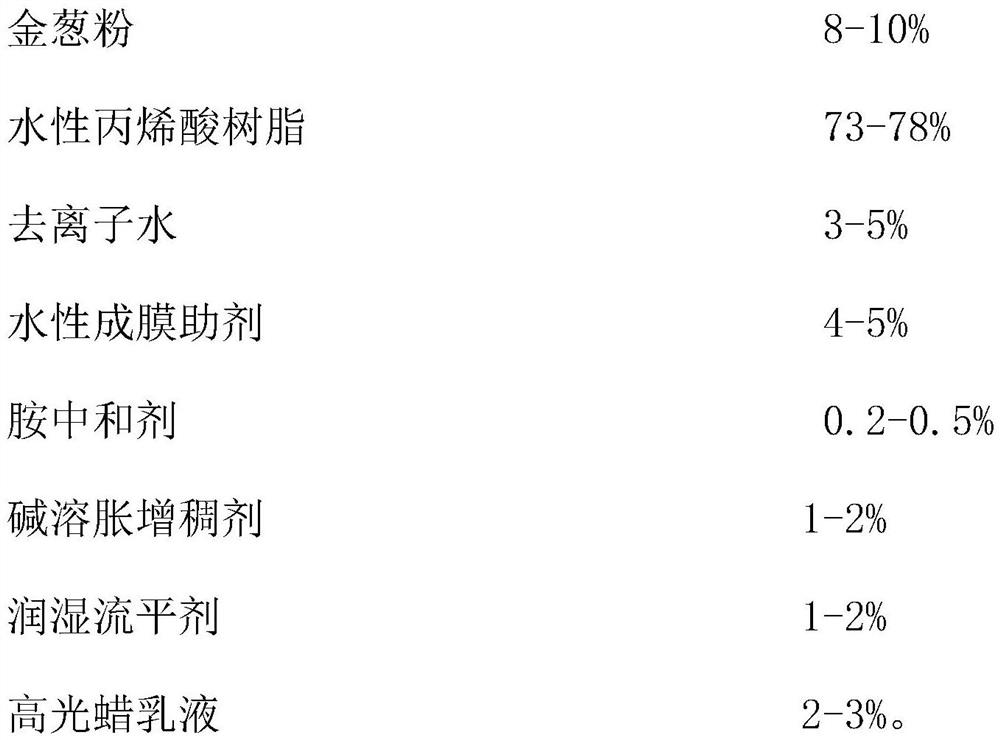

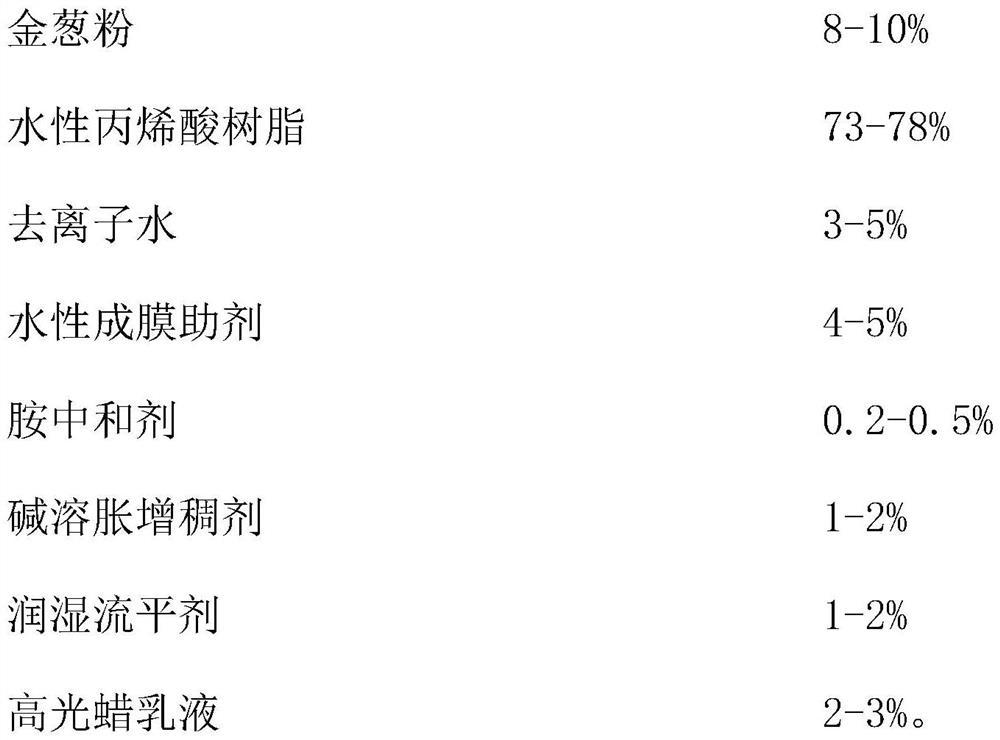

Method used

Image

Examples

Embodiment 1-3

[0027] A preparation method of water-based fan printing varnish ink, comprising the following steps:

[0028] (1) take each component by weight part of table 1;

[0029] (2) Mix the aqueous acrylic emulsion and deionized water evenly to form a solution;

[0030] (3) Add the amine neutralizer and water-based film-forming aid to the above solution, and turn on the high-speed mixer at a temperature of 25-35°C, with a stirring rate of 600 rpm; stir for 20 minutes until all are dissolved, and prepare a semi-finished product A;

[0031] (4) On the basis of semi-finished product A, slowly add wetting agent, alkali-swellable thickener, high-gloss wax, and glitter powder, turn on the high-speed mixer, stir at a speed of 800 rpm, and fully stir for 5 minutes to prepare the finished product.

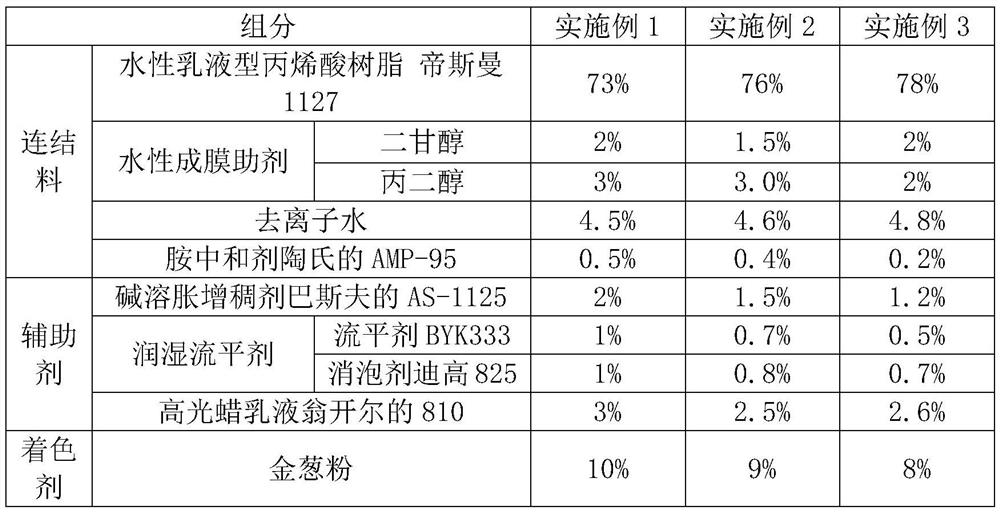

[0032] Table 1: The weight proportion of the aqueous vermicelli printing varnish ink of embodiment 1~3

[0033]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap