Coal-pillar-free roof-cutting gob-side entry retaining inner roof supporting resistance calculation method

A roof support and resistance calculation technology, applied in calculation, earthwork drilling, design optimization/simulation, etc., can solve problems such as inaccurate results, and achieve the effect of reasonable calculation method and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

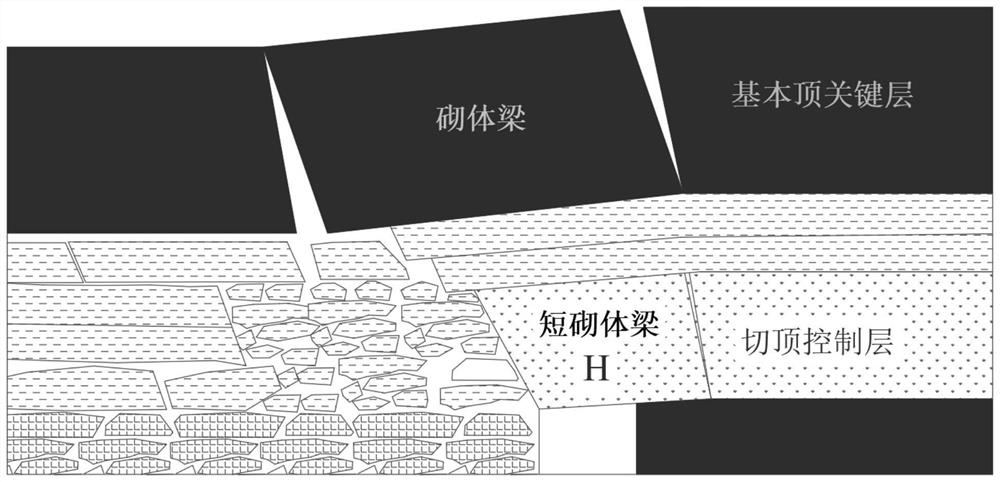

[0128] Project Overview

[0129] The 50107 working face of Dongdong Coal Mine adopts the method of retaining gob-side roadway without coal pillars, with a slope depth of 8.3m and an angle of 15°. The thickness of the direct roof is 2m, outside the range of the cut roof, the thickness of the weak rock layer is 3.3m, the thickness of the basic roof is 9m, the mining height is 3.4m, and the body force of the bedrock is 0.027MN / m 3 , the average body force of the load layer is 0.023MN / m 3 .

[0130] Determination of roof support resistance in roadway

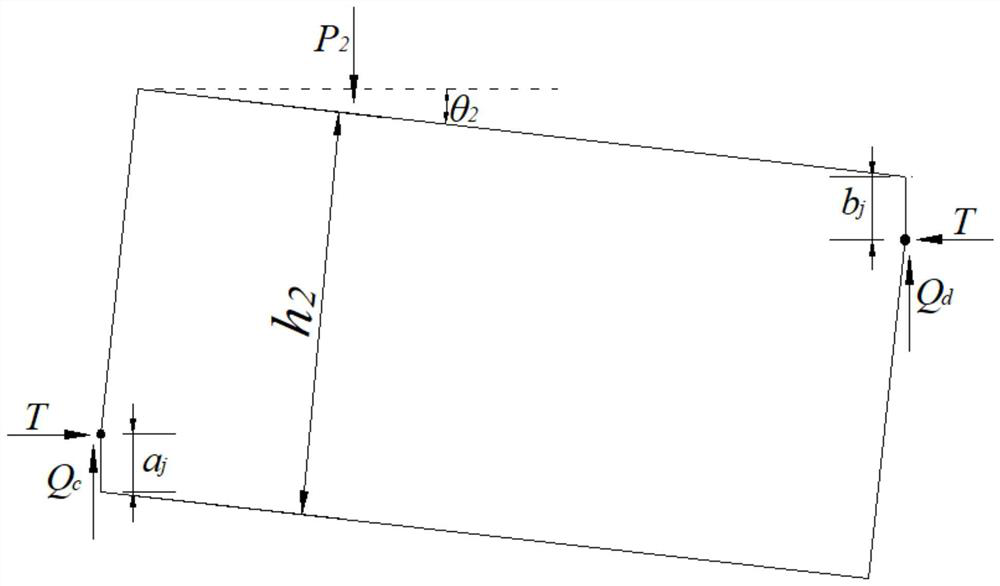

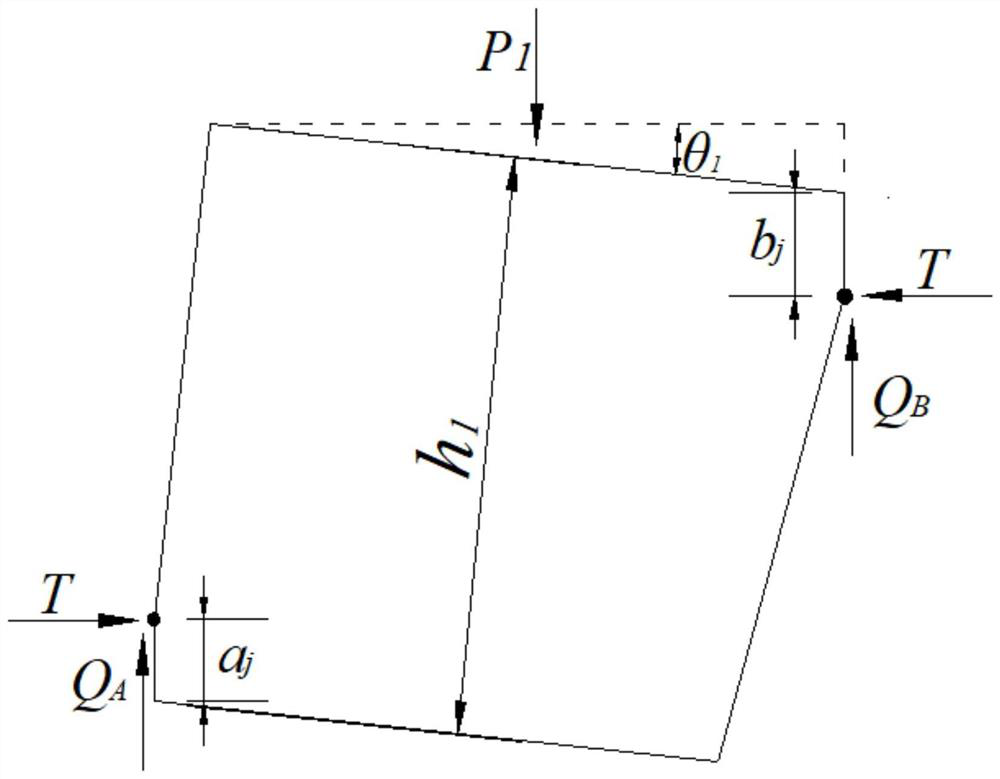

[0131] 1) According to the fracture structure characteristics of the top-cut control layer within the range of the top-cut height and the fracture structure outside the range of the top-cut height in the overlying rock of the Dongdong Coal Mine without coal pillars, the basic top is broken laterally to form a masonry beam Structure, the top cutting controls the breakage of the rock layer to form a short masonry structure, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com