Safety control method and safety control system for battery vibration test

A technology for safety control and vibration testing, applied in general control systems, control/regulation systems, vibration testing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

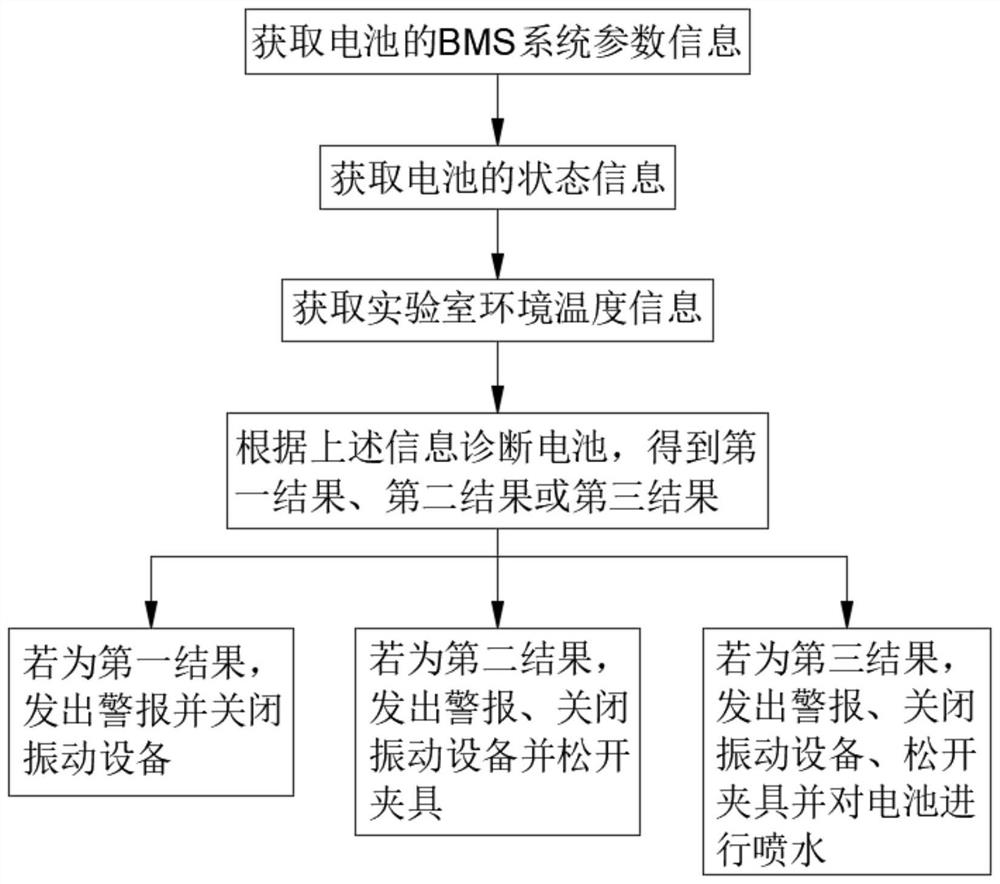

[0049] like figure 1 As shown, this embodiment provides a safety control method for a battery vibration test. The vibration test is performed on the battery by using a vibration device. The vibration device includes at least one clamp for clamping the battery. The safety control method includes the following steps:

[0050] S110. Acquire parameter information of the BMS system of the battery; the parameter information includes a thermal runaway signal, a maximum voltage and a minimum voltage, a total voltage, all cell temperatures and all cell voltages.

[0051] Among them, the BMS system of the battery can monitor the status of the battery in real time, including the voltage of the battery and the voltage and temperature of all cells. The BMS system can also monitor whether the battery has thermal runaway, and will report a thermal runaway signal when the battery has thermal runaway.

[0052] S120. Acquire status information of the battery; the status information includes the...

Embodiment 2

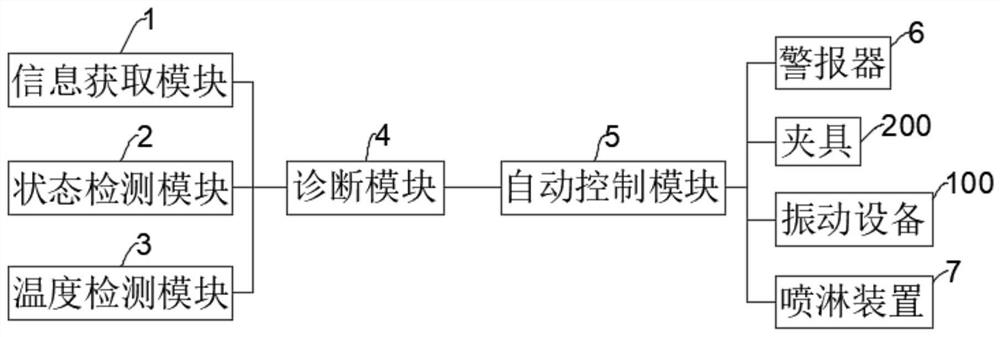

[0066] like figure 2 As shown, this embodiment provides a safety control system for battery vibration test, and the system can execute the safety control method for battery vibration test described in the above-mentioned embodiments; The device 100 includes at least one clamp 200 for holding the battery, and the safety control system includes an information acquisition module 1, a state detection module 2, a temperature detection module 3, a diagnosis module 4, an automatic control module 5, an alarm 6 and a spray device 7 , the information acquisition module 1 is used to acquire the parameter information of the BMS system of the battery; the parameter information includes the thermal runaway signal, the maximum voltage and the minimum voltage, the total voltage, the temperature of all cells and the voltage of all cells; the state detection module 2 is used to acquire the battery The status information includes the temperature of the battery and whether the battery produces s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com