Electric drive unit, hybrid module, and drive assembly for motor vehicle

An electric drive unit and motor vehicle technology, applied to the electric drive unit, can solve the problems of motor loss, insufficient cooling of the most heated area, insufficient cooling, etc., and achieve the effect of improving efficiency and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

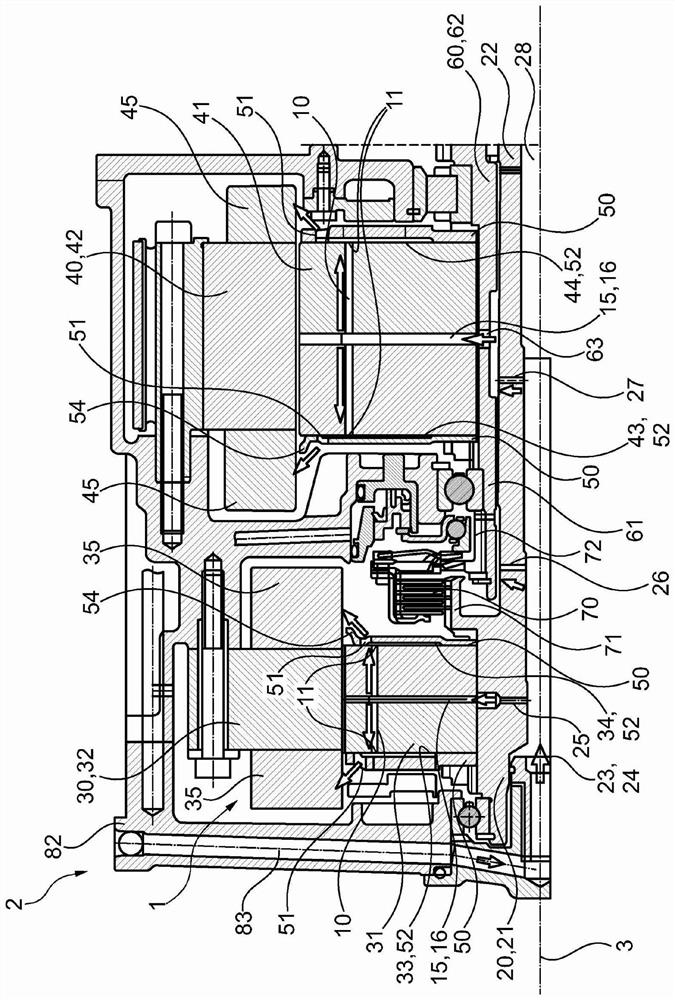

[0078] exist figure 1 A cutaway side view of a hybrid module 2 according to the invention is shown in .

[0079] The hybrid module 2 here comprises an electric drive unit 1 designed according to the invention, which has a drive shaft 20 and a first electric rotary machine 30 , the rotor 31 of which is fixedly connected to the drive shaft. 20 coupling. Furthermore, the hybrid module 2 includes a second rotary machine 40 , the rotor 41 of which is arranged in a rotationally fixed manner on the output shaft 60 , and a clutch arrangement 70 .

[0080] The driven shaft 60 is connected at its first axial end section 61 to the clutch device 70 and here forms an output side 72 of the clutch device 70 , wherein the input side 71 of the clutch device 70 is formed by the drive shaft 20 . The clutch device 70 is here arranged axially between the two electric rotary machines 30 , 40 .

[0081] The drive shaft 20 is designed as a hollow shaft and is radially surrounded in parts by a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com