Preparation method of hollow fiber membrane based on PTFE

A fiber membrane and hollow technology, which is applied in the field of PTFE-based hollow fiber membrane preparation, can solve the problems of uneven fiber membrane strength, lower production quality of the device, and easy wrinkling of the device during winding, so as to avoid uneven incision and good tension degree, not easy to clean the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

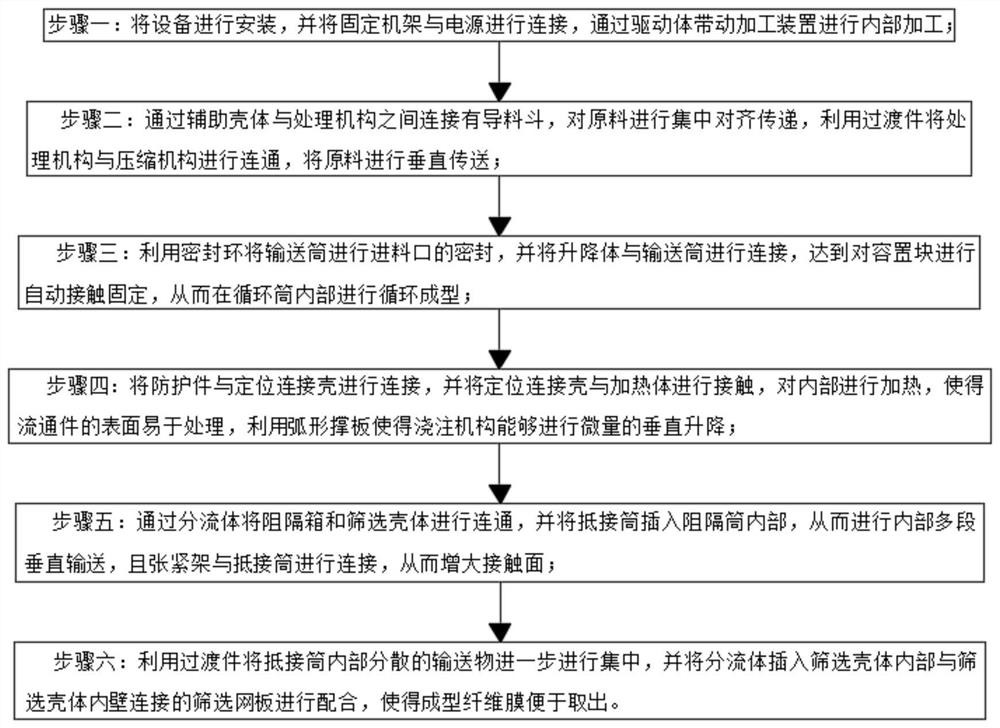

[0039] see Figure 1-5, the present invention provides a technical solution: a method for preparing hollow fiber membranes based on PTFE, comprising a fixed frame 2, a controller 1 is fixedly connected to the middle position of the top outer wall on the right side of the fixed frame 2, and the top of the fixed frame 2 The middle position on the right is provided with a driving body 3, and the top of the fixed frame 2 is fixedly connected with a blocking frame 4 at both sides of the driving body 3, and a processing device 5 is arranged at the middle position on the left side of the top of the fixed frame 2. The top is communicated with feed pipe 6.

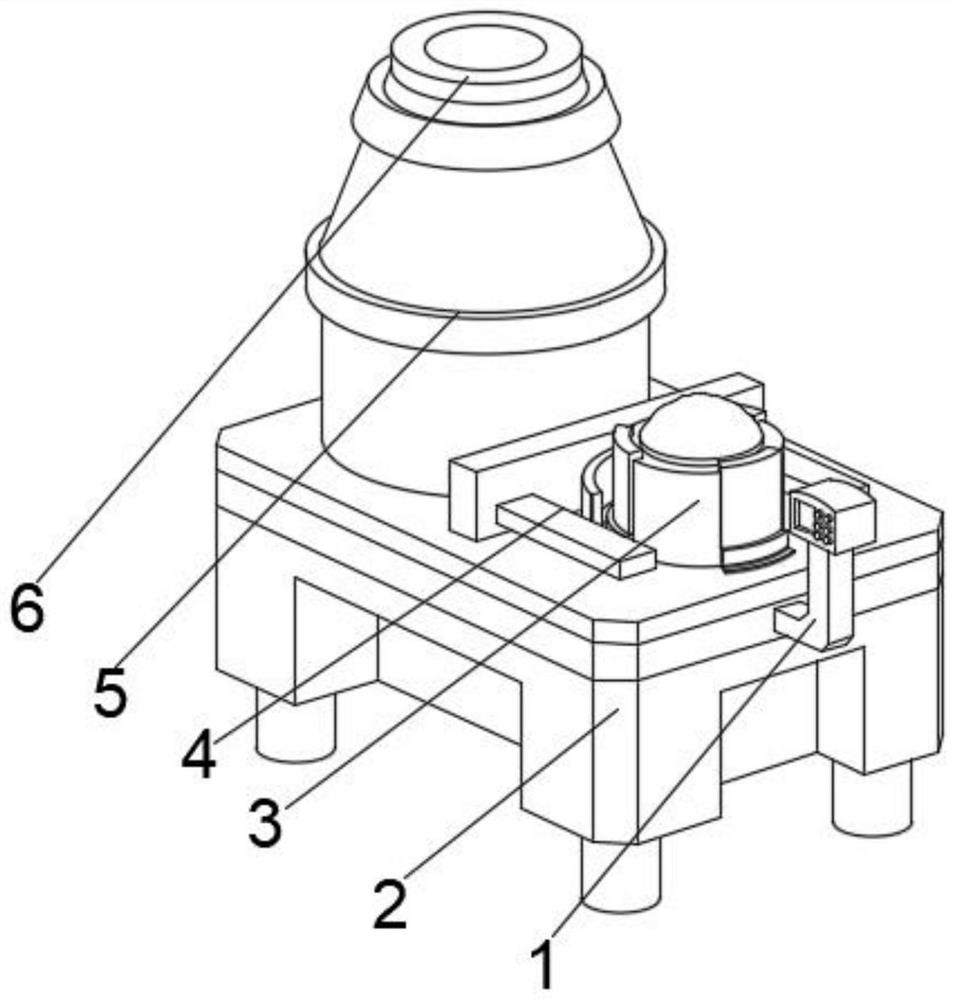

[0040] Wherein, the processing device 5 includes an isolation cylinder 51, a compression mechanism 52 is arranged at the middle position of the inner cavity bottom of the isolation cylinder 51, a transition piece 53 is arranged on the top of the compression mechanism 52, and a processing mechanism 54 is fixedly connected to the top...

Embodiment 2

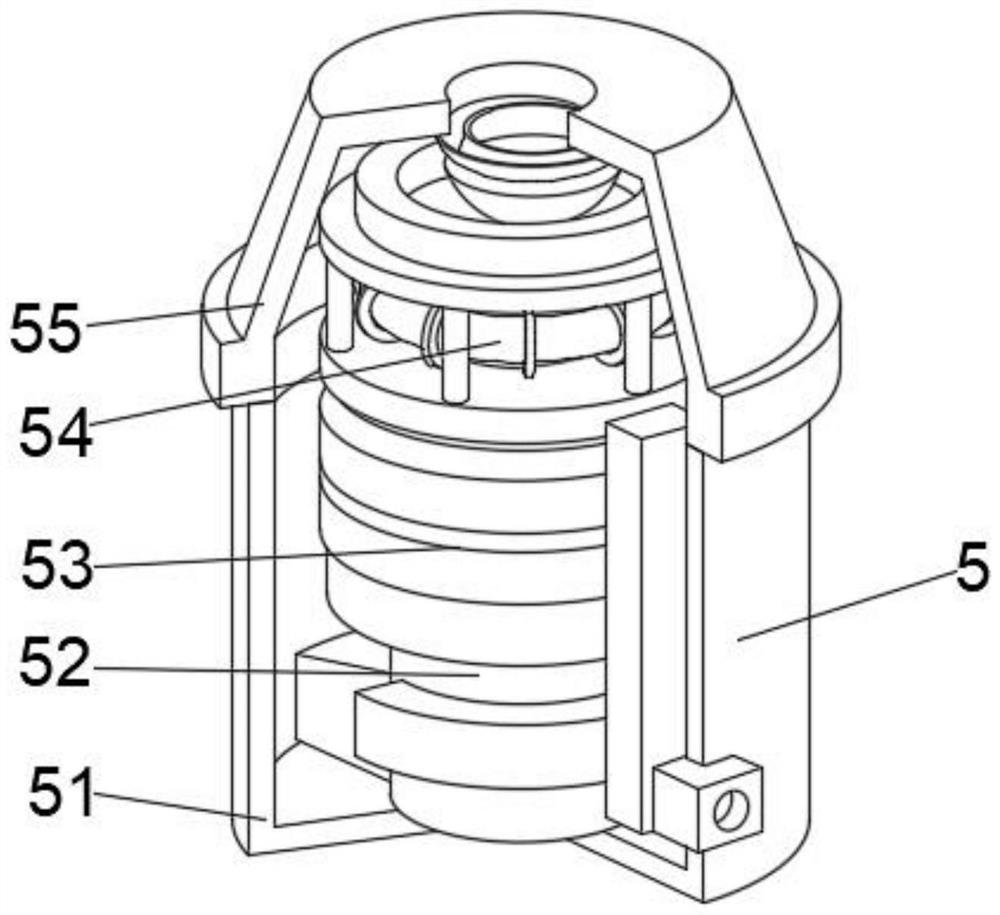

[0045] see Figure 1-5 , On the basis of Embodiment 1, the present invention provides a technical solution: a method for preparing hollow fiber membranes based on PTFE, step 1: install the equipment, and connect the fixed frame 2 to the power supply, and pass The driving body 3 drives the processing device 5 to perform internal processing;

[0046] Step 2: Through the guide hopper connected between the auxiliary housing 55 and the processing mechanism 54, the raw materials are collectively aligned and delivered, and the transition piece 53 is used to communicate the processing mechanism 54 with the compression mechanism 52, and the raw materials are conveyed vertically;

[0047] Step 3: Use the sealing ring 522 to seal the feeding port of the conveying cylinder 521, and connect the lifting body 523 to the conveying cylinder 521, so as to automatically contact and fix the accommodating block 524, thereby performing cycle molding inside the circulation cylinder 525 ;

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com