Bolt assembling and disassembling device based on magnetic adsorption and using method thereof

A loading and unloading device, magnetic adsorption technology, applied in workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve problems such as difficult loading and unloading of bolts, bolt corrosion, nut and screw co-rotation, etc., to improve loading and unloading efficiency and easy operation. , Improve the effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

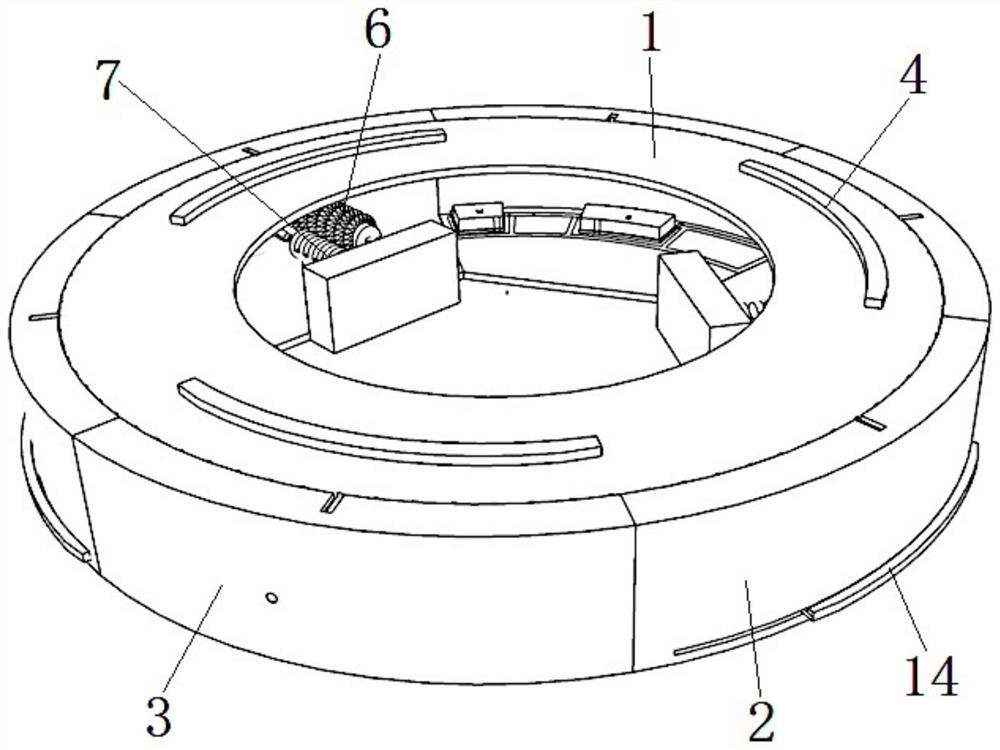

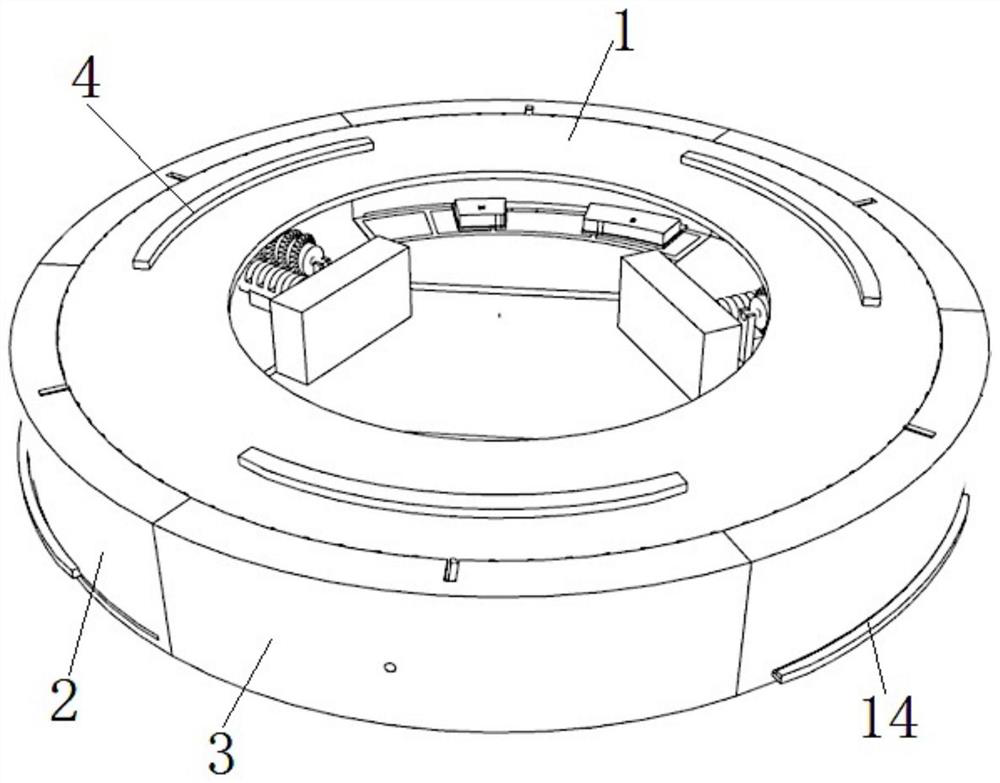

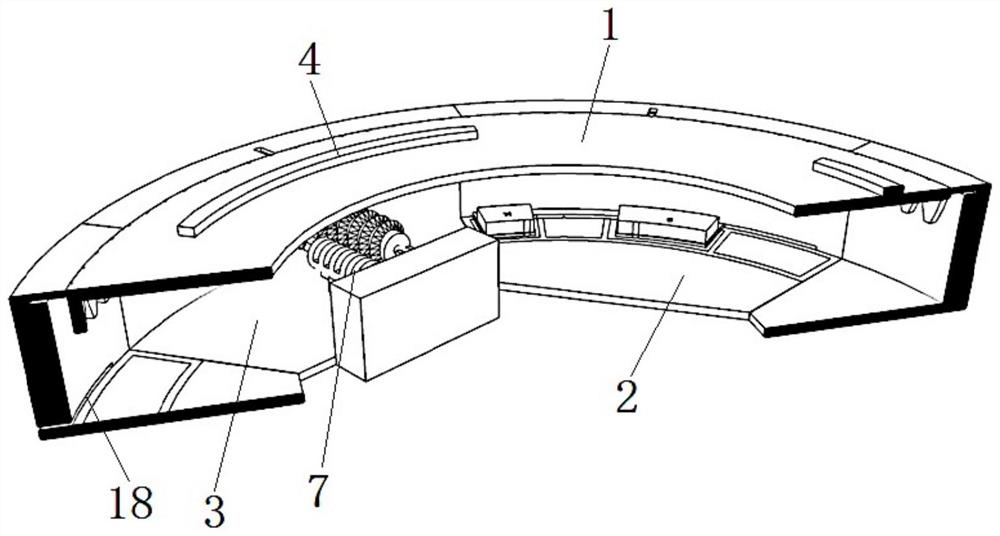

[0059] as attached Figure 1-9 As shown, this embodiment provides a bolt loading and unloading device based on magnetic adsorption, which includes an upper cover 1, three magnetic bases 2 and three fastening bases 3; the three magnetic bases 2 and three fastening bases 3 are distributed at intervals , and sequentially spliced to form an annular base; the annular base is sleeved outside the nuts of the bolts to be loaded and unloaded; each magnetic base 2 is provided with a magnetic structure, and the magnetic force structure is connected to the working surface of the bolts to be loaded and unloaded by magnetic force; each The fastening base 3 is provided with a fastening mechanism, and the fastening mechanism is arranged radially along the ring-shaped base; the output end of the fastening mechanism is set toward the center of the ring-shaped base, and is used to fix the nuts of the bolts to be loaded and unloaded; the upper cover 1 is rotated and set On the annular base, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com