Production method and equipment for reducing salt content and solid waste of p-methylphenol

A technology of p-cresol and production method, which is applied in chemical instruments and methods, preparation of organic compounds, water/sludge/sewage treatment, etc. Process flow, reduce unit consumption, and avoid the effect of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

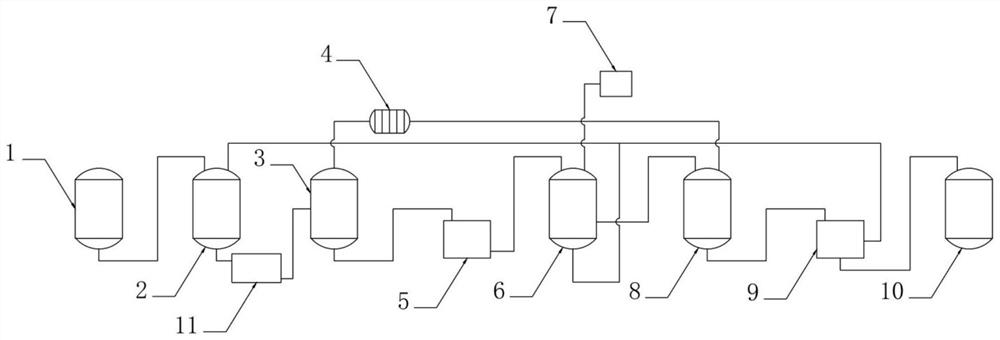

[0037] A production device for reducing the salt content and solid waste of p-cresol, comprising an alkali-dissolving tank 1, a digester 2, a flash tank 3, a scrubber 8 and a rectifying tank 10. The alkali-dissolving kettle 1 is connected with the digester 2; the digester 2 is connected with the trough 11; the trough 11 is connected with the flash tank 3; the top of the flash tank 3 is connected with the heat exchanger 4, The bottom of the flash tank 3 is connected with the centrifuge 5; the centrifuge 5 is connected with the acidifier 6; the acidifier 6 is connected with the neutralization section 7; the acidifier 6 is connected with the scrubber 8; the scrubber 8 is connected with phenol-water separator 9; said phenol-water separator 9 is connected with rectifying tank 10 and digester 2 respectively; said heat exchanger 4 is connected with scrubber 8; said acidifier 6 is connected with digester 2 .

Embodiment 2

[0039] In the equipment of embodiment 1, carry out the production of a batch of p-cresol, concrete process is as follows:

[0040](1) Digestion section: 500g of sodium p-toluenesulfonate as raw materials, 222g of sodium hydroxide, and an alkali melting temperature of 364°C. After the reaction, the molten sample and water are impregnated in the digester, the amount of impregnation water is 2500g, and the impregnation water is general production water; the impregnation temperature is controlled at 100°C to obtain a high-temperature solid-liquid mixture, which overflows to the digestion tank;

[0041] (2) Flashing section: the high-temperature mixture with a temperature of 363°C is transported to the flash tank through pipelines for flash evaporation, wherein the temperature of the flash tank is controlled at 50°C, and the water vapor after flashing is condensed to 45°C by a heat exchanger , the remaining solid-liquid mixture is pumped into the centrifuge section;

[0042] (3) C...

Embodiment 3

[0048] In the equipment of embodiment 1, carry out the production of a batch of p-cresol, concrete process is as follows:

[0049] (1) Digestion section: 500g of sodium p-toluenesulfonate as raw materials, 225g of sodium hydroxide, and an alkali melting temperature of 357°C. After the reaction, the molten sample and water were dipped in the digester, the amount of dipping water was 2600g, and the dipping water was the liquid separated from step (4) and step (6) in Example 2; the temperature of the dipping was controlled at 97°C to obtain The high-temperature solid-liquid mixture overflows to the digestion tank;

[0050] (2) Flashing section: the high-temperature mixture with a temperature of 363°C is transported to the flash tank through pipelines for flash evaporation, wherein the temperature of the flash tank is controlled at 52°C, and the water vapor after flashing is condensed to 46°C by a heat exchanger , the remaining solid-liquid mixture is pumped into the centrifuge s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap