All-solid-waste-based carbonated unfired lightweight aggregate and preparation method thereof

A carbonation and lightweight aggregate technology, applied in the field of solid waste resource utilization and building materials, can solve the problems of aggravated pollution and greenhouse effect, high production cost, high cost, etc., to reduce costs and solve low-value and low-volume utilization problems, effects of saving natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

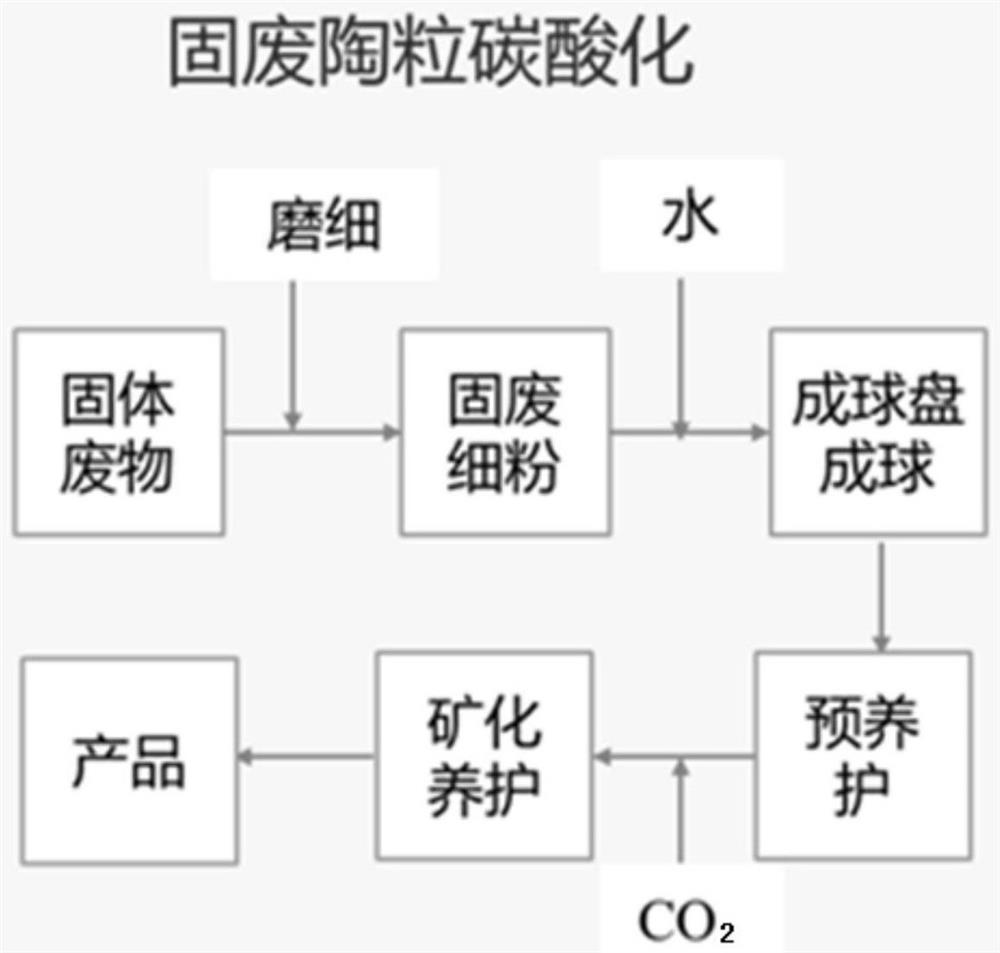

Method used

Image

Examples

Embodiment 1

[0047] In this example, blast furnace slag is selected for the active component type solid waste, fly ash is selected for the light filling type solid waste, and calcium carbide slag is selected for the alkali-activated solid waste;

[0048] Grind blast furnace slag, fly ash and carbide slag separately, and mix them in proportion to obtain mixed solid waste powder with a particle size of less than 100 μm. In the mixed solid waste powder, the weight ratio of blast furnace slag, fly ash and carbide slag is 1.5 :1:0.075;

[0049] Take the mixed solid waste powder and water with a mass ratio of 1:0.2, divide the mixed solid waste powder into the first part and the second part according to the mass ratio of 2:1, fully mix the first part of the mixed solid waste powder with water and place it in the Granulate in a ball pan (rotating speed of the ball plate is 30r / min, ball forming time is 30min); another spare water is used for granulation spray supplementation, until the first part...

Embodiment 2

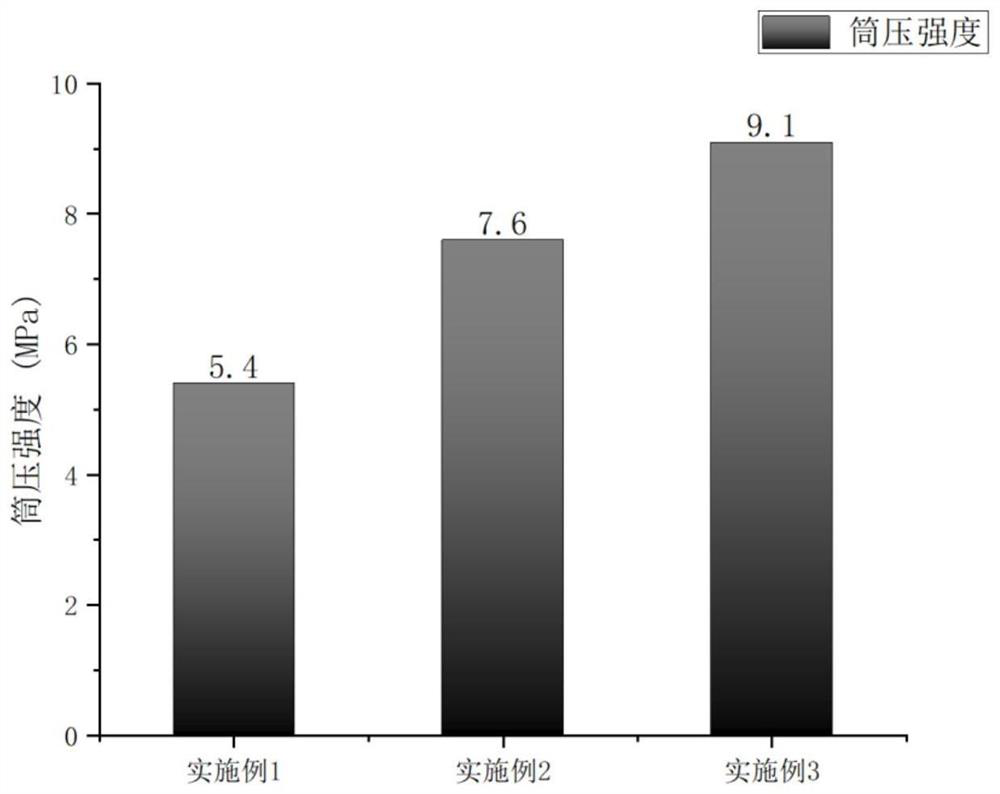

[0053] The preparation method of all solid waste-based carbonated burn-free lightweight aggregate in this example is the same as in Example 1. In the mixed solid waste powder, the weight ratio of blast furnace slag, fly ash and carbide slag is 1.5:1:0.125.

[0054] Such as figure 2 As shown, the cylinder compressive strength of the all-solid waste-based carbonated burn-free lightweight aggregate prepared in this example is 7.6 MPa.

Embodiment 3

[0056] The preparation method of all-solid waste-based carbonation non-burning lightweight aggregate in this embodiment is the same as that of Example 1, the only difference is that after mineralization curing, under the condition of replenishing water, 4 days of natural curing are carried out to obtain the described All solid waste-based carbonated non-burning light aggregate.

[0057] Such as figure 2 As shown, the cylinder compressive strength of the all-solid waste-based carbonated burn-free lightweight aggregate prepared in this example is 9.1 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap