Aqueous coating agent composition

A technology of coating agent and composition, which is applied in the field of water-based emulsion-type coating agent composition, and can solve the problems of uniform coating property of coating agent, non-adhesive water repellency, insufficient lubricity and adhesiveness, etc. , to achieve the effects of excellent adhesion, low coefficient of friction and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

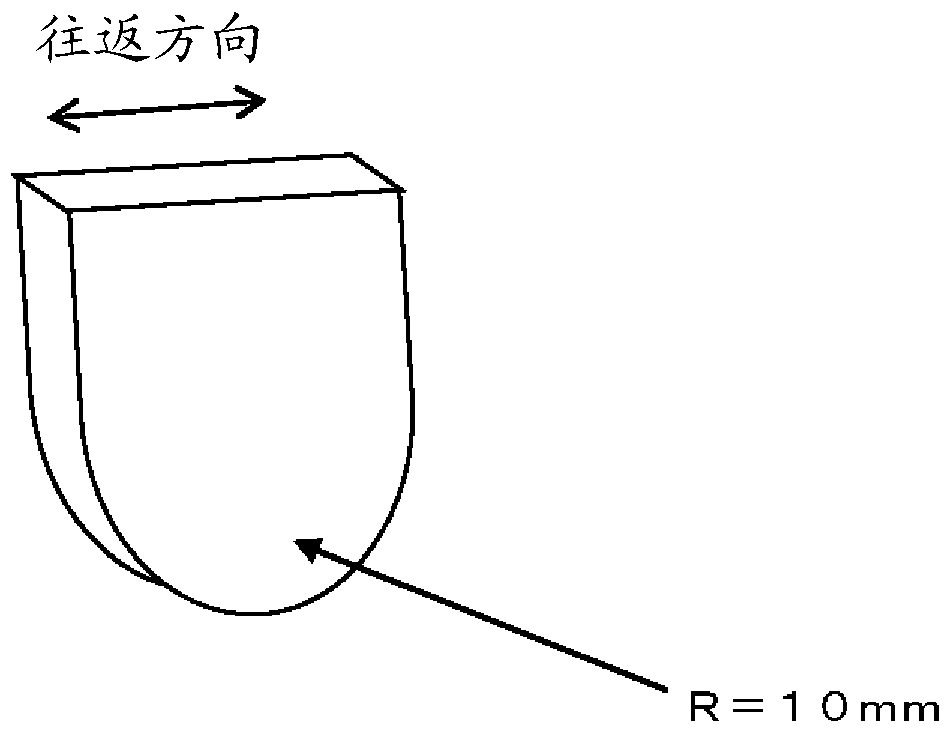

Image

Examples

Embodiment 1~15

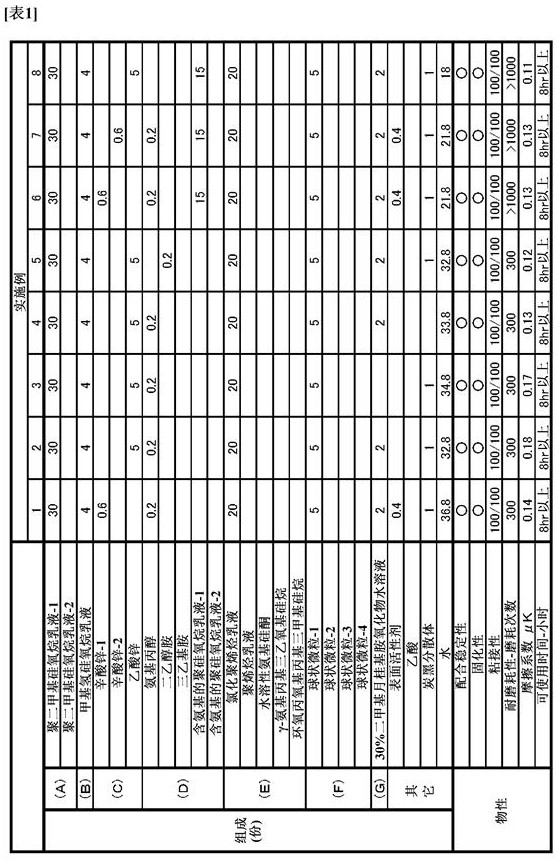

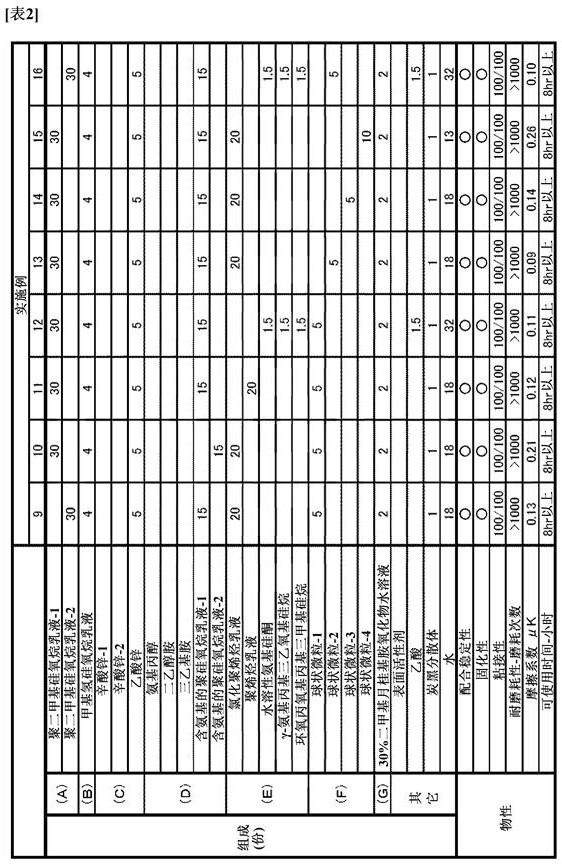

[0107] Examples 1 to 15 and Comparative Examples 1 to 7

[0108] As shown in Table 1 to Table 3 to form each component of the fitting shown in Table, the aqueous coating composition was prepared. Incidentally, in Examples and Example 6, not directly add zinc octylate, but premixed with the surfactant added 1 embodiment. Further, in addition to the particularly stated, an emulsion with water as a dispersion medium.

[0109] Details of each component in the table below.

[0110]

[0111] · Polydimethylsiloxane emulsion -1

[0112] Ratio of 50% at the end of 1,400,000mPa · s viscosity containing a hydroxy terminated polydimethylsiloxane emulsion polymerization of

[0113] · Polydimethylsiloxane emulsion -2

[0114] At a ratio of 50% 10,000,000mPa · s viscosity containing terminal hydroxyl terminated polydimethylsiloxane emulsion mechanical emulsification

[0115]

[0116] Methyl hydrogen siloxane emulsion

[0117] Containing a ratio of 30% of the average formula: (CH 3 ) 3 SiO (CH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com