Tool enzyme separation device with high mixing efficiency

A technology of mixing efficiency and separation device, which is applied in the field of tool enzyme separation device, can solve the problems of low mixing efficiency and achieve the effect of improving mixing effect, improving relaxation efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

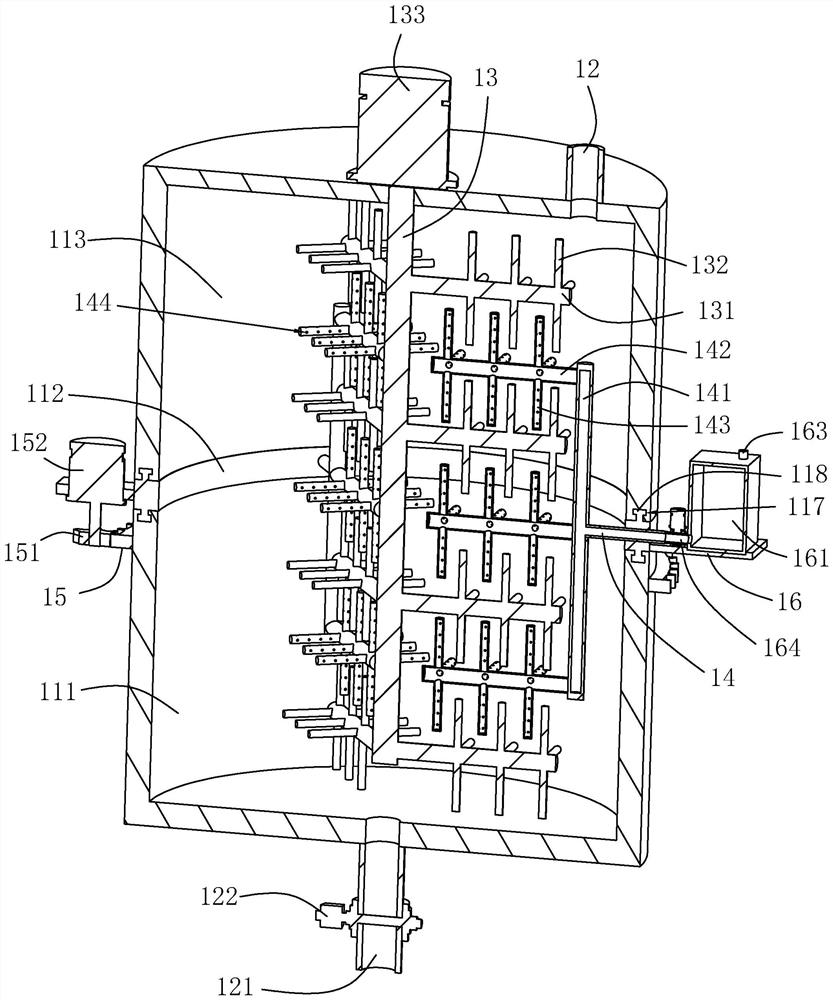

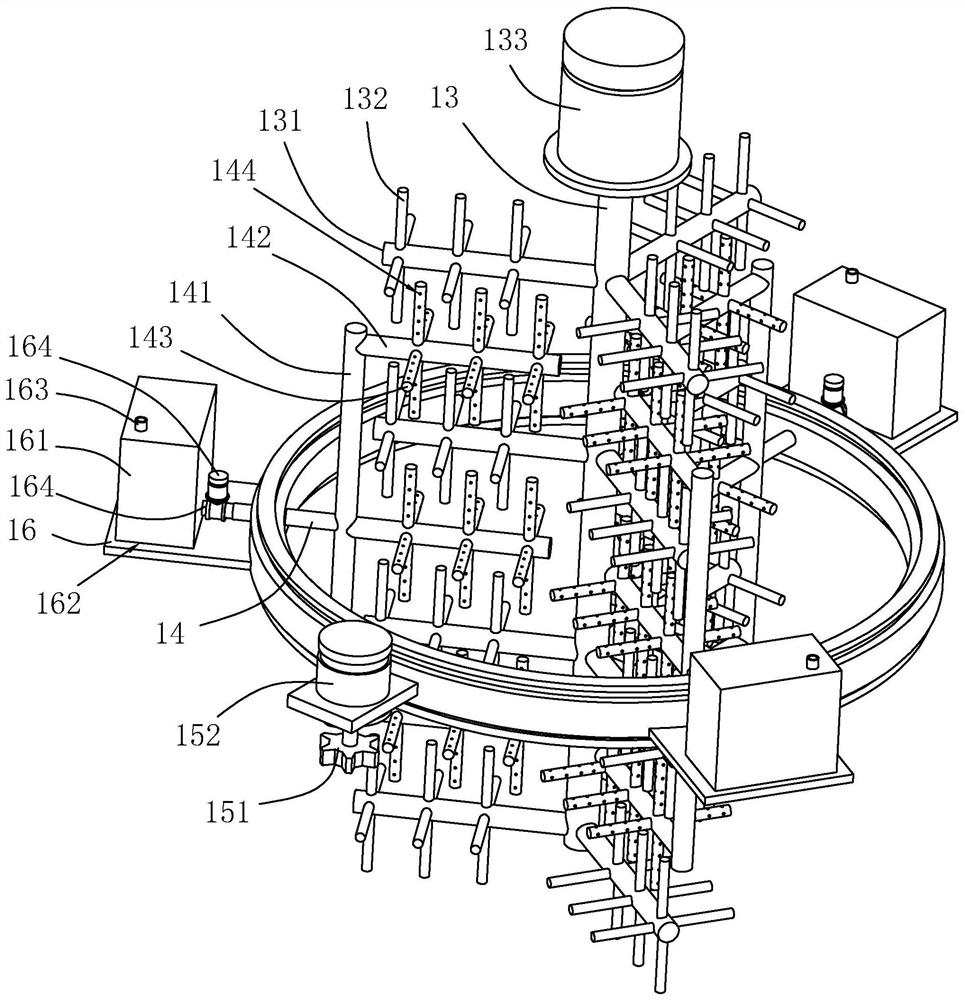

[0033] The following is attached Figure 1-3 The application is described in further detail.

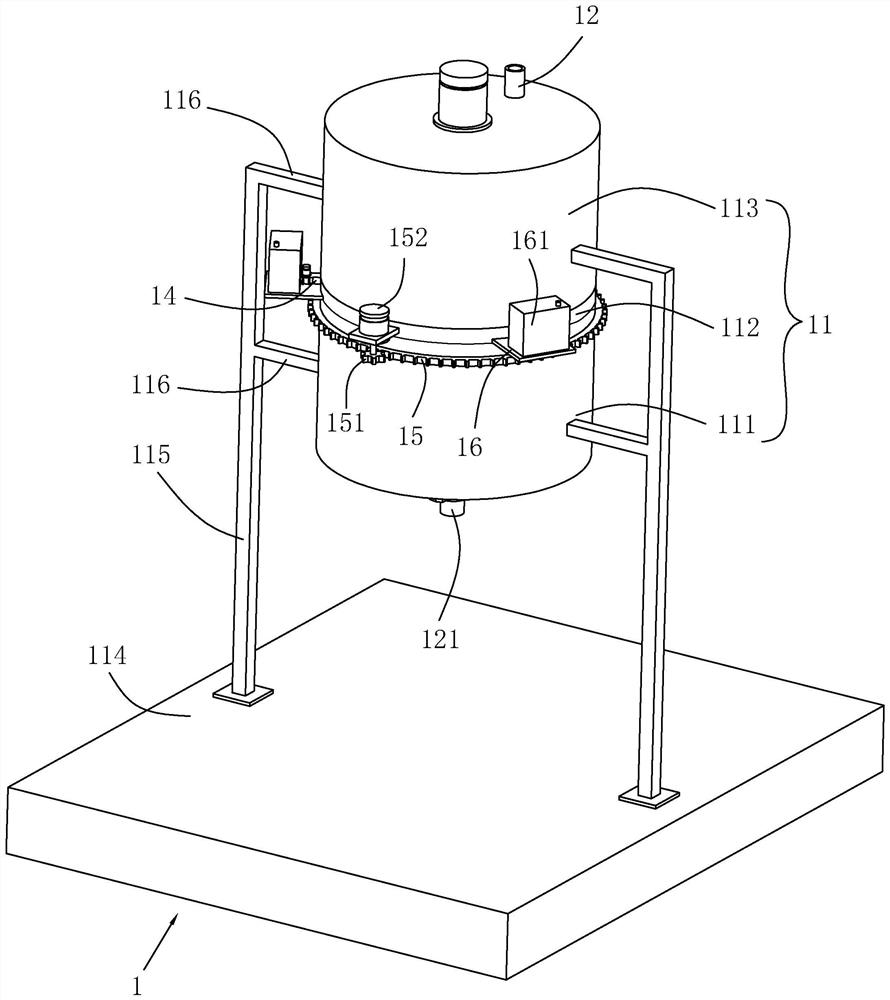

[0034] The embodiment of the present application discloses a tool enzyme separation device with high mixing efficiency. refer to figure 1 , a tool enzyme separation device with high mixing efficiency, comprising a frame body 1 and a box body 11 arranged on the frame body 1, the cross section of the box body 11 is circularly arranged, and the box body 11 includes a lower casing 111, an annular plate 112 and an upper casing 113, the frame body 1 includes a bottom plate 114, a vertical bar 115 fixedly arranged on the bottom plate 114 and located on both sides of the bottom plate 114, and a cross bar 116 perpendicular to the vertical bar 115 and arranged on the upper and lower parts of the vertical bar 115, The lower casing 111 is fixedly arranged on the lower crossbar 116, the upper casing 113 is fixedly arranged on the upper crossbar 116, the lower casing 111 and the upper casing 113...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com