Asphalt pouring device for building

A construction and asphalt technology, applied in the field of construction asphalt pouring devices, can solve the problems of inability to heat asphalt and difficult rotation of the screw rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

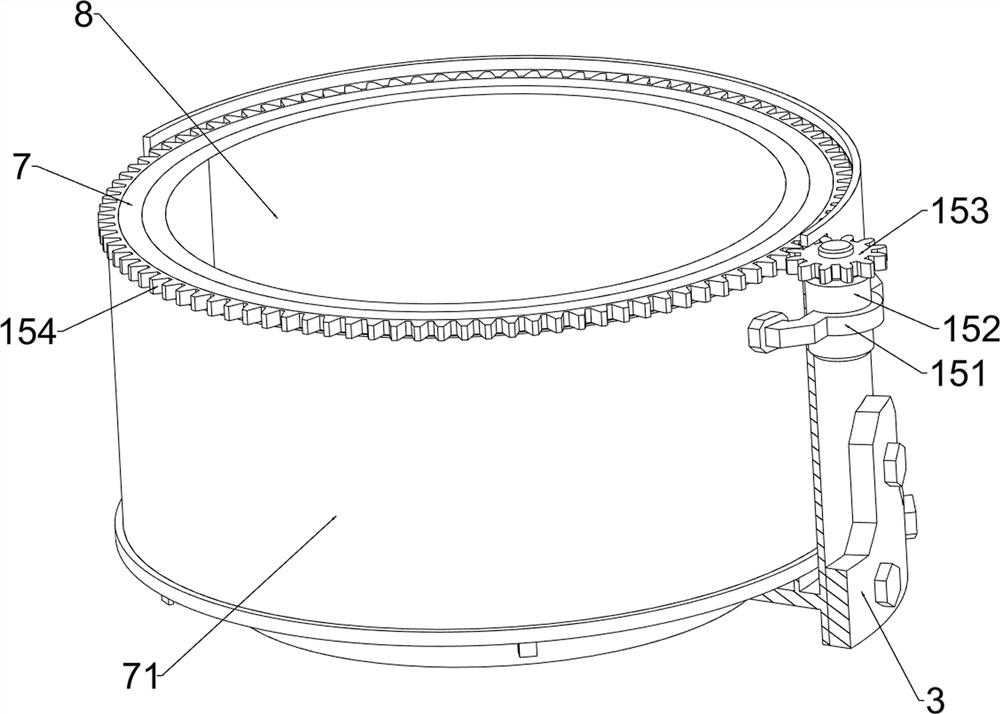

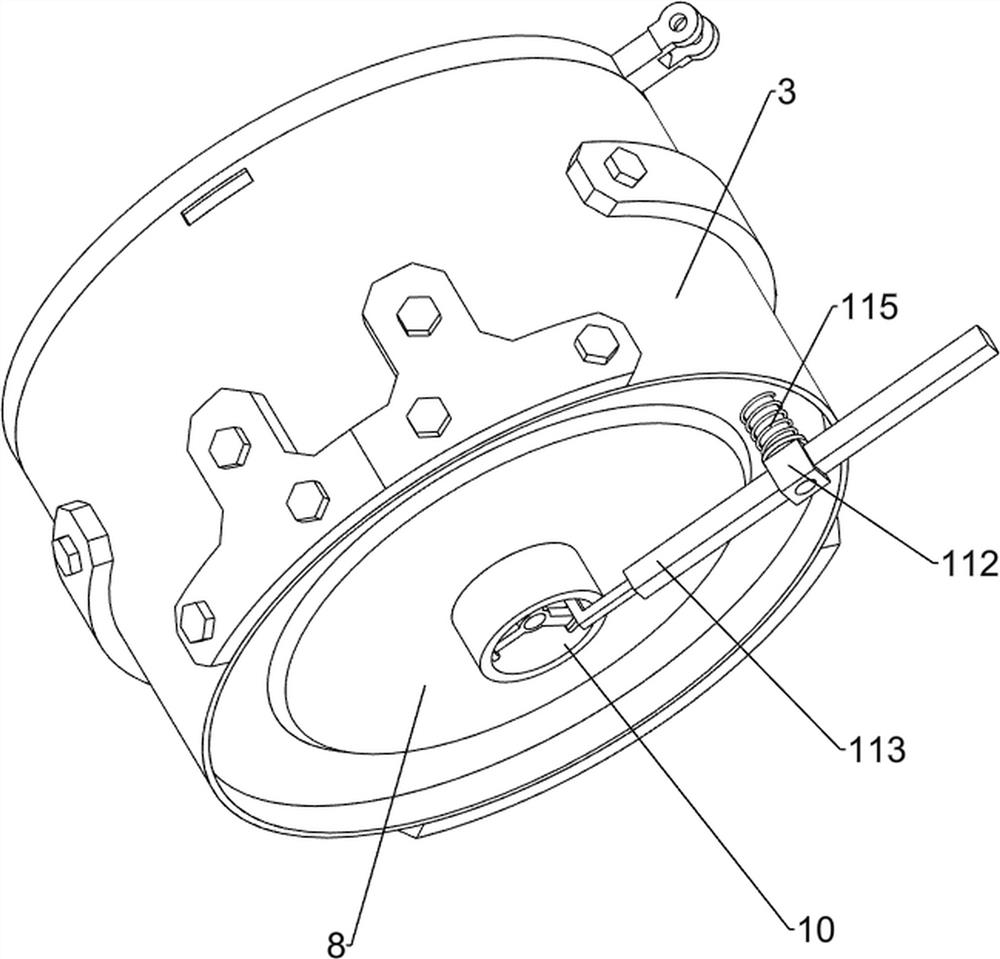

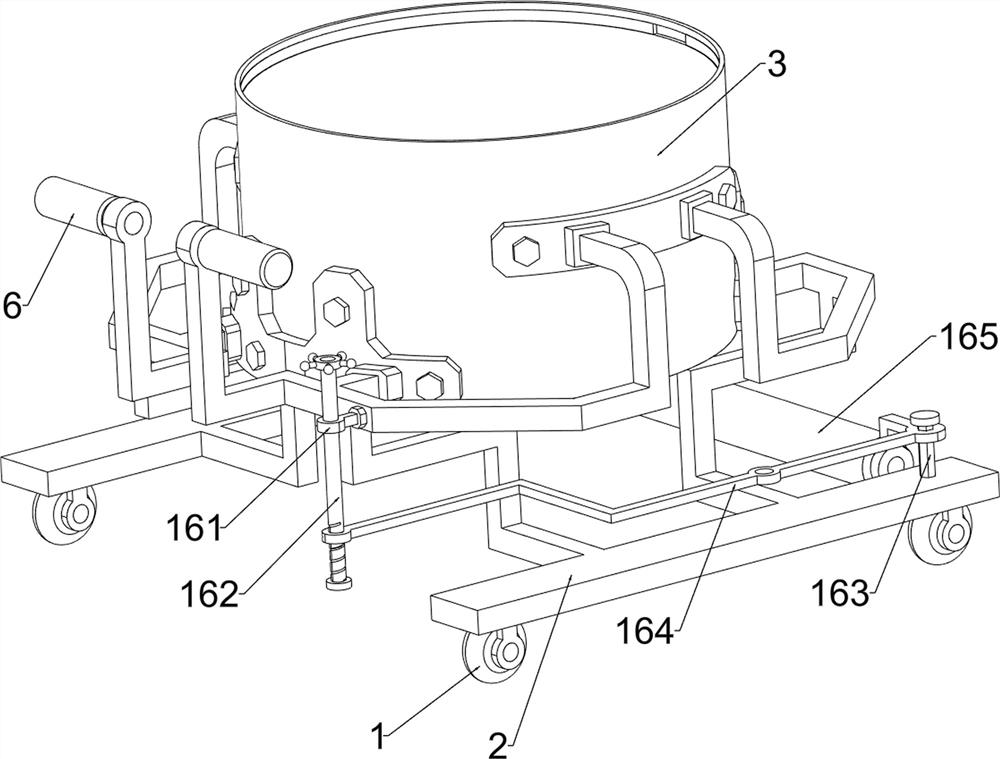

[0037] An asphalt pouring device for construction, such as Figure 1-6 As shown, it includes a roller 1, a connecting frame 2, a casing 3, a first fixed block 4, a flip cover 5, a handle 6, a turret 7, a heat conducting layer 71, a charging frame 8, a heating wire 9, a discharge pipe 10, The unloading mechanism 11 and the stirring mechanism 12, the four corners of the lower side of the connecting frame 2 are all rotatably provided with rollers 1, the upper part of the connecting frame 2 is connected with the shell 3 by means of bolt connection, and the right side of the upper part of the shell 3 is connected by means of a bolt connection. The first fixed block 4, the first fixed block 4 is provided with a flip cover 5 in a rotating cover, the shape of the flip cover 5 is circular, the flip cover 5 is engaged with the upper side of the shell 3, and the upper rear part of the connecting frame 2 is covered with two handles. The handle 6 and the inner casing 3 are rotatably provid...

Embodiment 2

[0042] On the basis of Example 1, such as figure 1 , Figure 7 and Figure 8 As shown, a filter mechanism 13 is also included, and the filter mechanism 13 includes an air outlet pipe 131, a rotating plate 132, a buckle 133 and activated carbon cotton 134; There is a rotating plate 132, and the lower part of the rotating plate 132 is connected with a buckle 133 by means of bolt connection. There is a slot on the outlet pipe 131, and the buckle 133 is engaged with the slot. The rotating plate 132 and the outlet pipe 131 are placed between There is activated carbon cotton 134.

[0043] The poisonous gas generated when the asphalt is heated will be discharged through the outlet pipe 131, and the activated carbon cotton 134 can filter and absorb the toxic gas generated when the asphalt is heated. The buckle 133 rotates counterclockwise to disengage the buckle 133 from the draw-in groove on the air outlet pipe 131. At this time, the operator can move the rotating plate 132 upward...

Embodiment 3

[0045] On the basis of Example 2, such as figure 1 and Figure 9 As shown, a transmission mechanism 14 is also included. The transmission mechanism 14 includes a second fixed block 141, a sliding frame 142, a rack 143 and a first spur gear 144, and the right part of the connecting frame 2 is connected with a second fixed block by means of bolts Block 141, the second fixed block 141 slides through a sliding frame 142, the sliding frame 142 is in contact with the lower pressing frame 113, the upper part of the sliding frame 142 is connected with a rack 143 by bolts, and the flip cover 5 and the first fixed block 4 A first spur gear 144 is sheathed at the rear of the joint, and the rack 143 meshes with the first spur gear 144 .

[0046] When the operator rotates clockwise to open the flip cover 5, the flip cover 5 will drive the first straight gear 144 to rotate clockwise, the first straight gear 144 will move the rack 143 downward, and the rack 143 will drive the sliding frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com