T-beam expansion joint integral post-pouring cross beam construction method

A construction method and technology of expansion joints, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as difficulty in controlling the line shape of pre-embedded steel bars, narrow space for demolding and demoulding, and large spans of poured steel bars for end-side guardrails. Solve the problem of not being damaged by fatigue and inconsistent installation of line type, facilitate the cross-span of beam-carrying vehicles, and solve the effect of crossing-span of beam-carrying vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

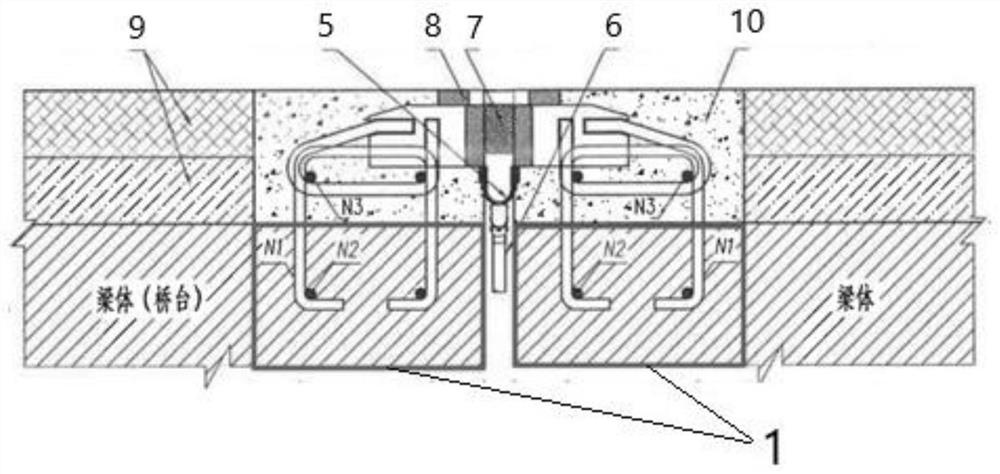

[0033] See figure 1 After pouring the whole beam T joints Example of the present embodiment provides a method of construction beams,

[0034] 1) In the additional slot of the main beam end joints 1;

[0035] 80 is a comb-type expansion joint plate joints, the size of a notch 35cm × 20cm, the size of the original reserve slots deepen;

[0036] 2) not embedded joints when erect steel prefabricated beams T, T the steel beams to rest upon the original design and construction, the T beam, first erect steel joints for construction design drawing, and then pouring slot joints 1 concrete;

[0037] 3) After the casting joints by cross beams T reservation steel top plate formed integrally with the beam connected to T beam construction is completed.

[0038] In this embodiment, the end joints in a predetermined slot in advance, without hanger bars embedded joints, so that the expansion joint reinforcement strong fatigue fracture, and mounting reinforcement linear manner consistent with the c...

Embodiment 2

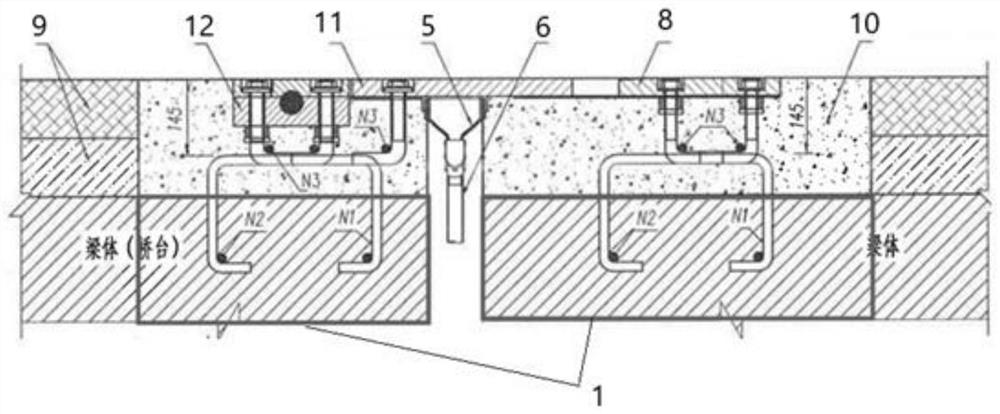

[0041] See figure 2 After pouring the whole beam T joints Example of the present embodiment provides a method of construction beams,

[0042] 1) In the additional slot of the main beam end joints 1;

[0043] Multi-cell expansion joints 160 joints to the displacement, the size of the slot 1 is 66cm × 20cm, the size of the original reserve slots deepen;

[0044] 2) not embedded joints when erect steel prefabricated beams T, T the steel beams to rest upon the original design and construction, the T beam, first erect steel joints for construction design drawing, and then pouring slot joints concrete;

[0045] 3) After the casting joints by cross beams T reservation steel top plate formed integrally with the beam connected to T beam construction is completed.

[0046] In this embodiment, the end joints in a predetermined slot in advance, without hanger bars embedded joints, so that the expansion joint reinforcement strong fatigue fracture, and mounting reinforcement linear manner consi...

Embodiment 3

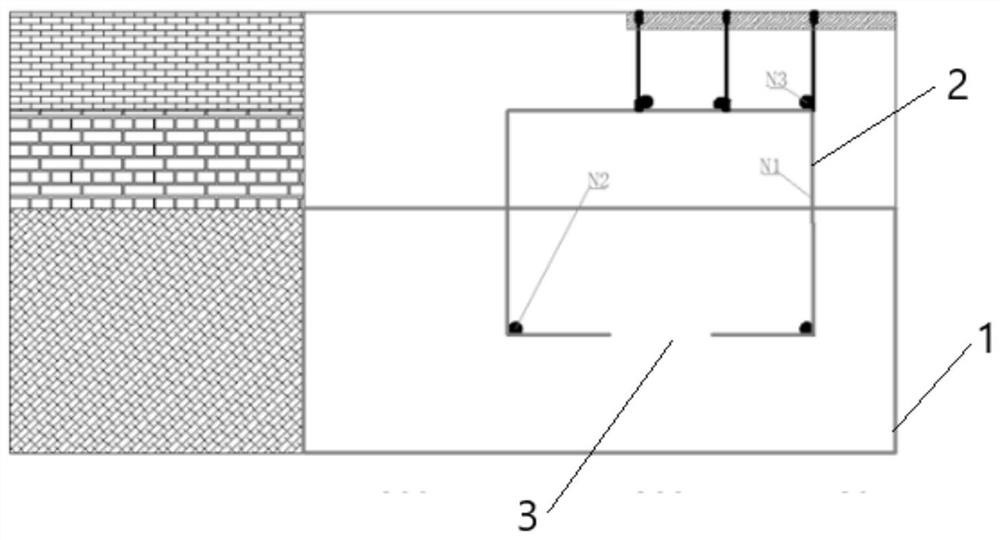

[0049] See image 3 On the basis of Example 1 and Example 2, at the T beam preformed, the end mold steel plate 2 with the reserved hole 3 is provided on the main beam body, and the end mold steel sheet 2 is accepted by the added slot 1. Place.

[0050] In the case, the position of the reserved hole 3 is determined according to the position of the steel bar on the main beam body, and the molded sheet is applied between the remaining gaps, reaches the slurry effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com