Using method of high-power high-frequency stroboscope lamp for rail visual inspection

A visual inspection, high-power technology, used in measuring devices, material analysis by optical means, instruments, etc., can solve problems such as inability to adapt to high-speed cameras, short light source exposure time, etc., to achieve short exposure time, increase heat transfer efficiency, and improve The effect of the fill light function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

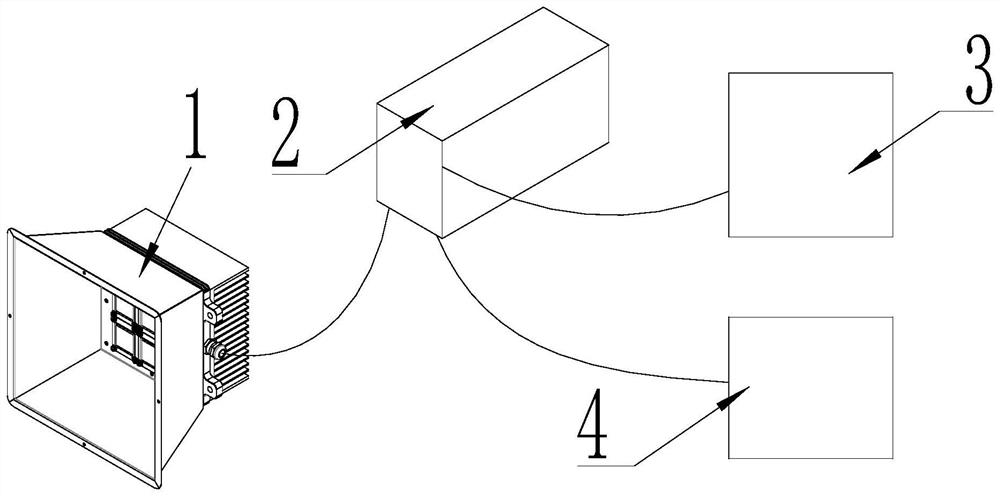

[0015] A control box 2 is set on one side of the strobe light 1, an external power supply 3 is set on one side of the control box 2, an external encoder 4 is set on one side of the external power supply 3, a wire is set between the strobe light 1 and the control box 2, and the control box 2 is connected to the external Wires are respectively arranged between the power supply 3 and the external encoder 4 .

Embodiment 2

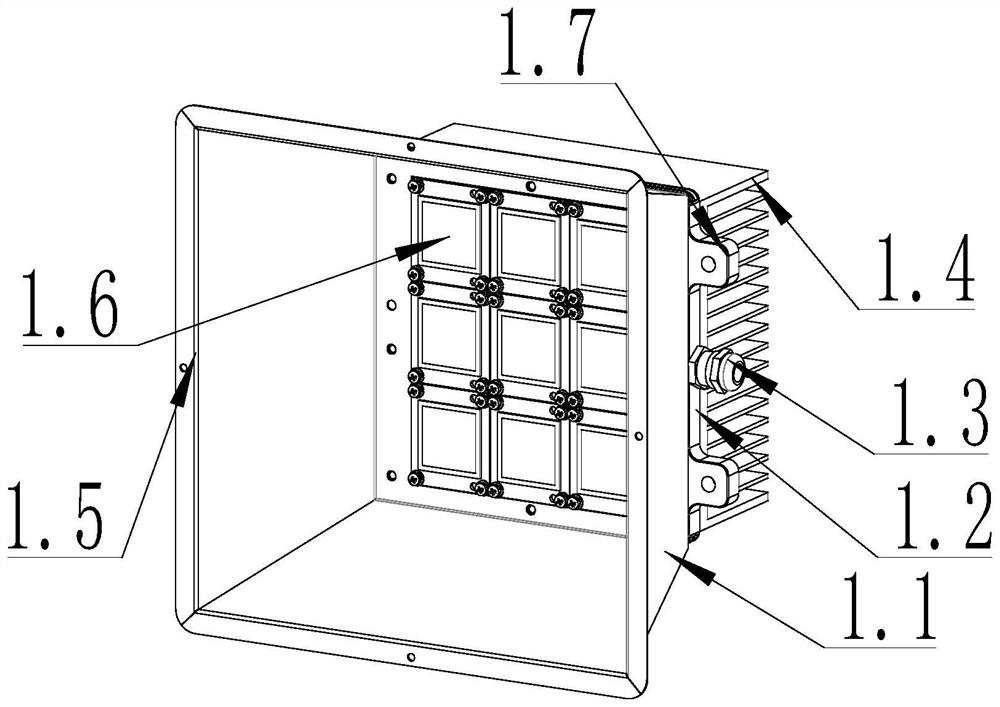

[0017] The structure of the strobe light 1 is as follows: the rear end of the lampshade 1.1 is provided with a lamp panel fixing plate 1.2, the rear end of the lamp panel fixing plate 1.2 is provided with a radiator 1.4, and one side of the lamp panel fixing plate 2 is provided with a cable waterproof connector 1.3, and the lamp panel is fixed. Light boards 1.6 are evenly distributed on the front side of the board 1.2, and the lamp boards 1.6 are located in the lampshade 1.1, and the front end of the lampshade 1.1 is provided with a phenanthrene mirror 1.5.

Embodiment 3

[0019] The strobe light 1 is installed on the detection site, the external power supply 3 and the line are used to supply power to the control box 2, the external encoder 4 is connected to the line to input signals to the control box 2, and the strobe power control circuit in the control box 2 is turned on and off To achieve the strobe effect of the strobe light 1, to meet the light supplement requirements of various high-speed cameras, the high-speed camera collects the image information that meets the requirements under the condition of supplementary light of the lamp, and calculates the detection results through computer processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com