Outdoor optical fiber connector and optical fiber adapter

An optical fiber connector and optical fiber adapter technology, applied in the field of optical fiber connection, can solve the problems of prolonged construction time, damage to optical fibers, poor waterproof performance, etc., and achieve the effect of avoiding random rotation, improving waterproofness, and good waterproofing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

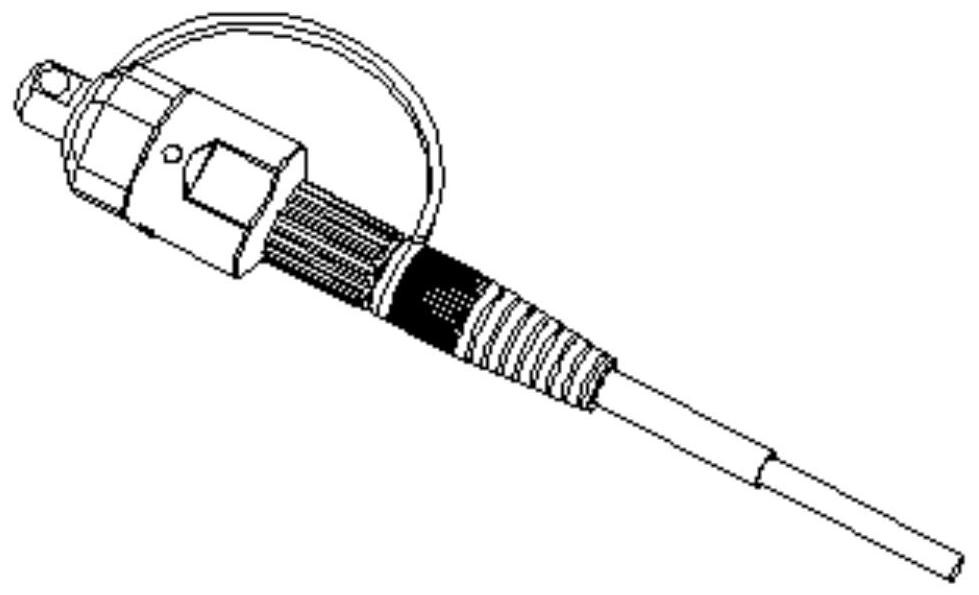

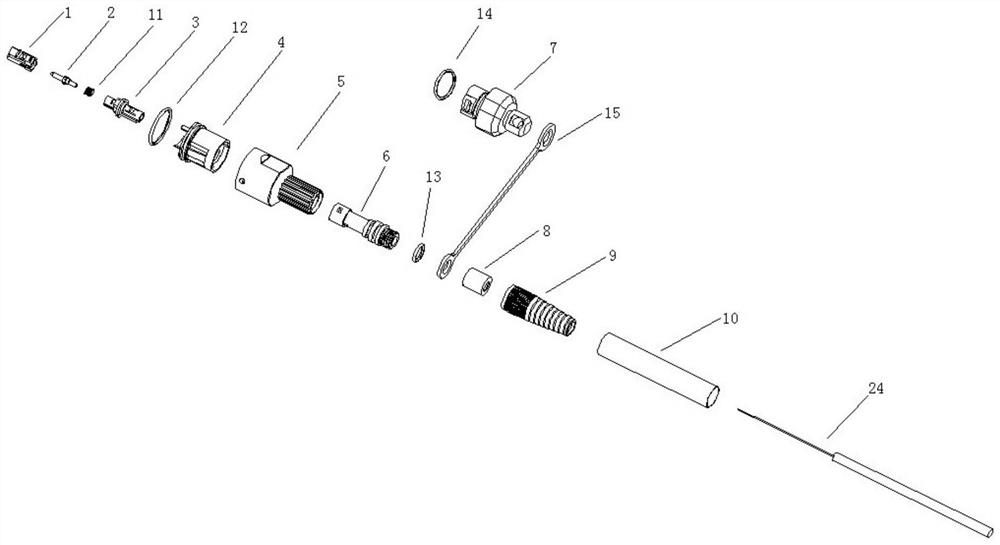

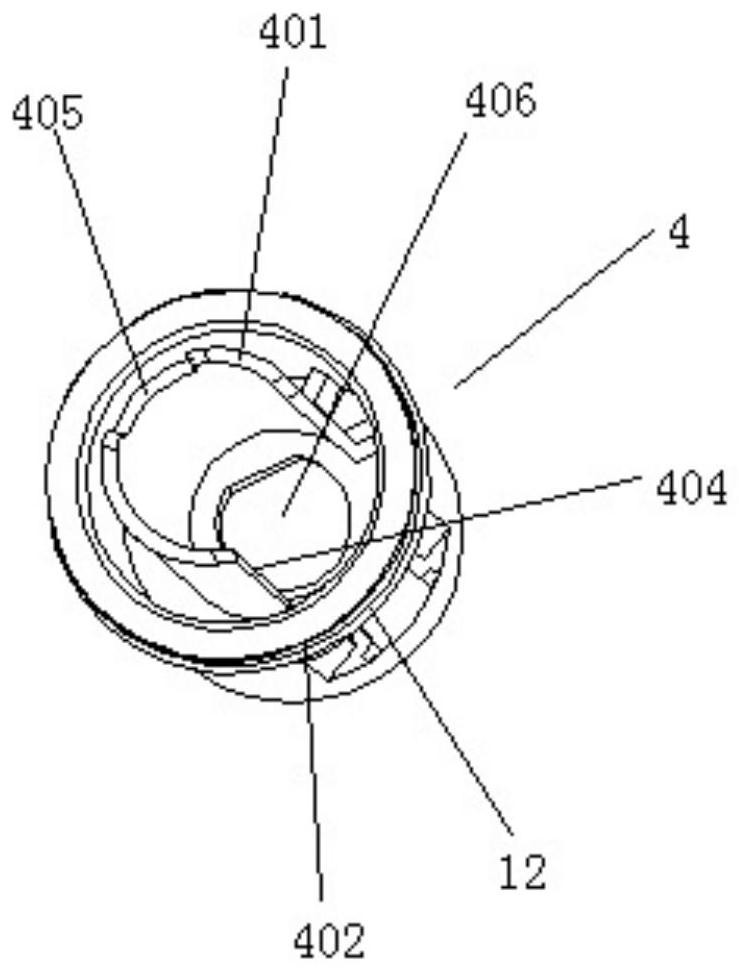

[0047] Embodiment 1: Reference Figure 1-19 , an outdoor optical fiber connector, including SC inner part 1, ferrule 2, inner card 3, ferrule 4, rotating shaft 5, inner rod 6, optical fiber 24, protective cap 7, pressure ring 8, heat shrinkable tube 9 and tail Sheath 10, the rotating shaft 5 is a hollow stepped cylindrical shape, the hoop 4 is installed in the large diameter end of the rotating shaft 5, the inner rod 6 is installed in the small diameter end of the rotating shaft 5, the SC inner part 1 and The inner card 3 is snapped together, the ferrule 2 is installed in the SC inner part 1 and the inner card 3, the inner card 3 is installed in the hoop 4 and the inner card 3 passes through the hoop 4 and is connected with the inner rod 6 in the rotating shaft 5, peeled off The opened optical fiber 24 passes through the inner rod 6 and is connected in the ferrule 2. The pressure ring 8 is arranged at the tail of the inner rod 6 to compress the aramid yarn on the optical fiber...

Embodiment 2

[0057] Embodiment 2: a kind of optical fiber adapter, refer to Figure 20-23 , for use with the outdoor optical fiber connector in Embodiment 1, including a main body seat 16, a ceramic sleeve 17, a U-shaped card 18, a nut 19 and an end cap 20, the main body seat 16 is cylindrical, and the main body seat 16 There is a protruding positioning plate 161 on the top, and the part of the main body seat 16 located on the front side of the positioning plate 161 is an insertion part 162 for inserting into the outer wall of the round ferrule 4 in the outdoor optical fiber connector and the positioning cylinder. The main body seat 16 The part located at the rear side of the positioning plate 161 is the mounting part 163, and the mounting part 163 is provided with a screw thread for connecting with the nut 19. The main body seat 16 is used to be installed on the wiring box, and the positioning plate 161 and the nut 19 can be connected The main body seat 16 is fixed on the wiring box, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com