Control system and method for industrial controller

A technology of industrial controllers and control systems, applied in general control systems, control/adjustment systems, program control, etc., can solve problems such as equipment work errors, command confusion, and mechanism operation errors, and achieve precise control, high practicability, and Avoid the effect of mechanism movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

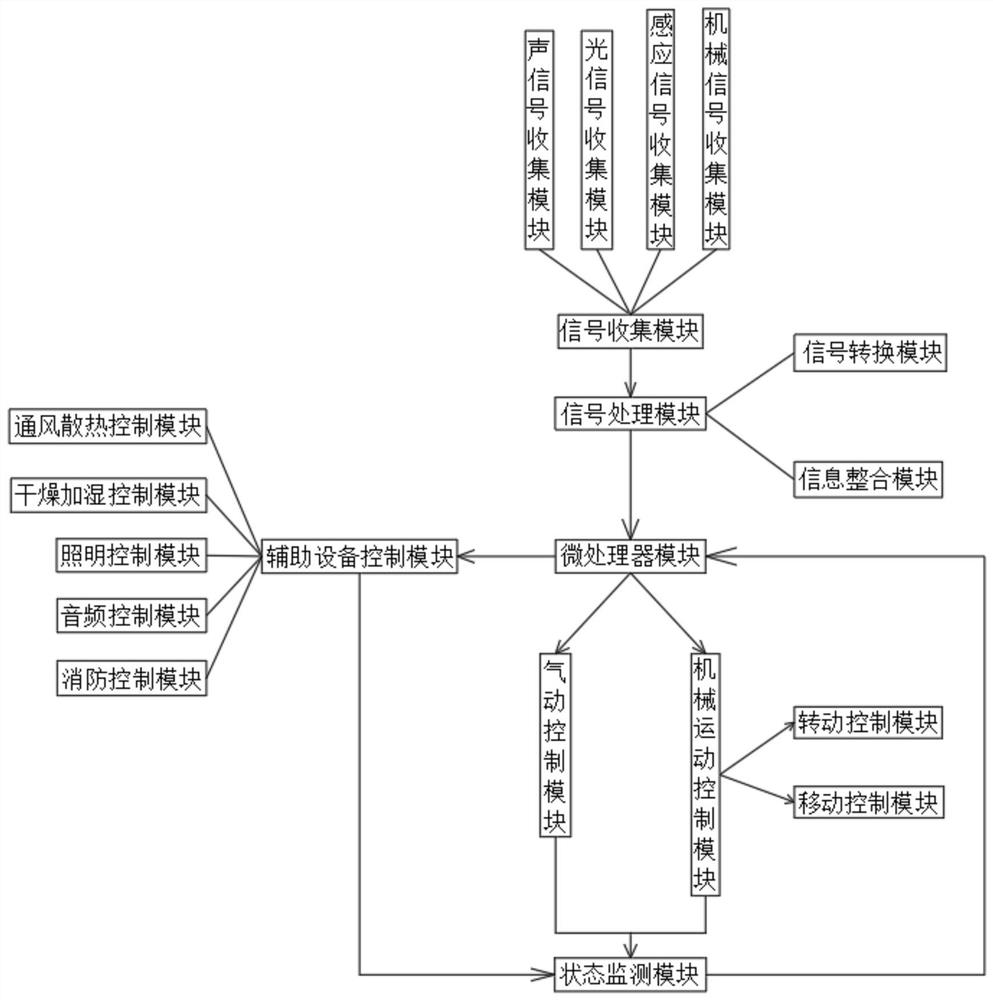

[0023] A control system of an industrial controller, including a microprocessor module, a signal collection module, a signal processing module, an auxiliary equipment control module, a pneumatic control module, a mechanical motion control module and a state monitoring module, and the signal collection module includes an acoustic signal collection module, Optical signal collection module, induction signal collection module and mechanical signal collection module, signal processing module includes signal conversion module and signal integration module, auxiliary equipment control module includes ventilation and heat dissipation control module, drying and humidification control module, lighting control module, audio control module and The fire control module and the mechanical motion control module include a rotation control module and a movement control module.

[0024] A control method for an industrial controller, comprising the following steps:

[0025] 1) The signal collecti...

Embodiment 2

[0037] A control system of an industrial controller, including a microprocessor module, a signal collection module, a signal processing module, an auxiliary equipment control module, a pneumatic control module, a mechanical motion control module and a state monitoring module, and the signal collection module includes an acoustic signal collection module, Optical signal collection module, induction signal collection module and mechanical signal collection module, signal processing module includes signal conversion module and signal integration module, auxiliary equipment control module includes ventilation and heat dissipation control module, drying and humidification control module, lighting control module, audio control module and The fire control module and the mechanical motion control module include a rotation control module and a movement control module.

[0038] A control method for an industrial controller, comprising the following steps:

[0039]1) The signal collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com