IBC solar cell structure of TOPCon back passivation contact structure and preparation method thereof

A solar cell and contact structure technology, which is applied in the field of solar cells, can solve the problems of unreasonable positive and negative electrode graphic design, large composite metal contact area, and difficult to distinguish, and achieve the effects of ensuring good contact, optimizing growth mode, and being easy to distinguish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

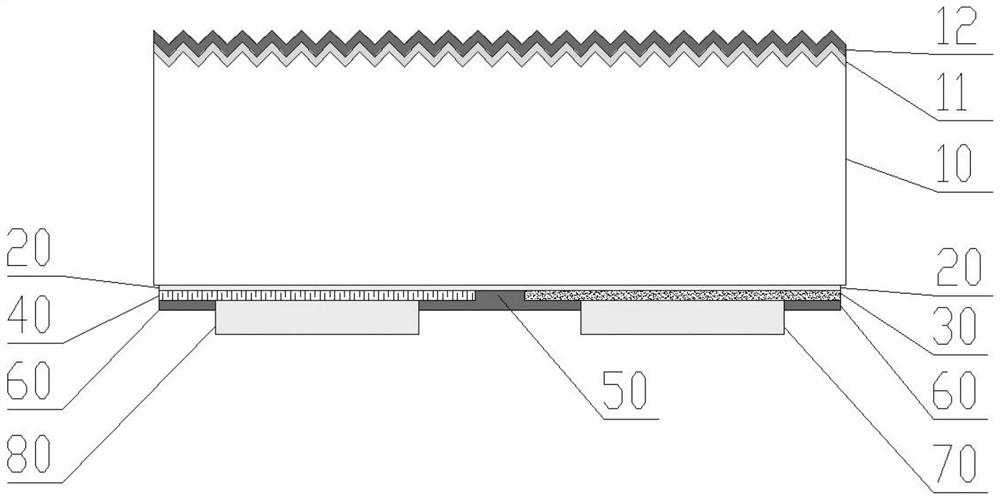

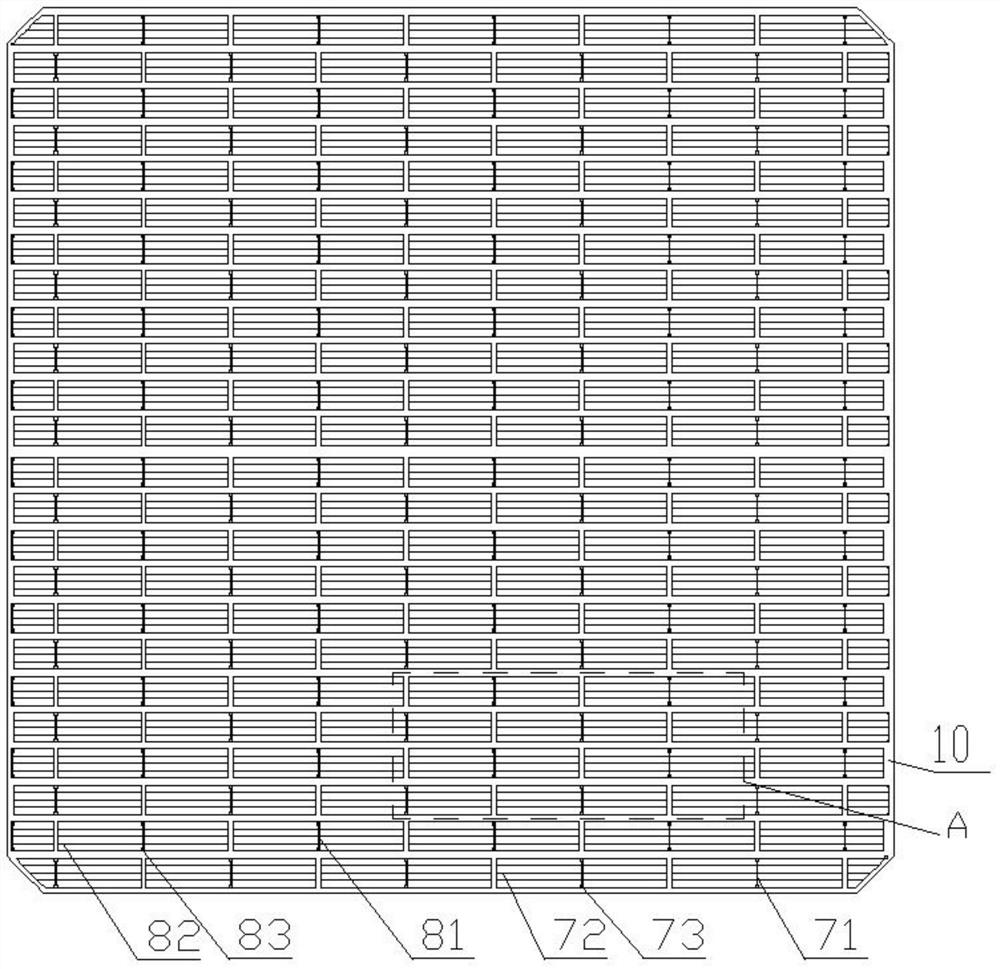

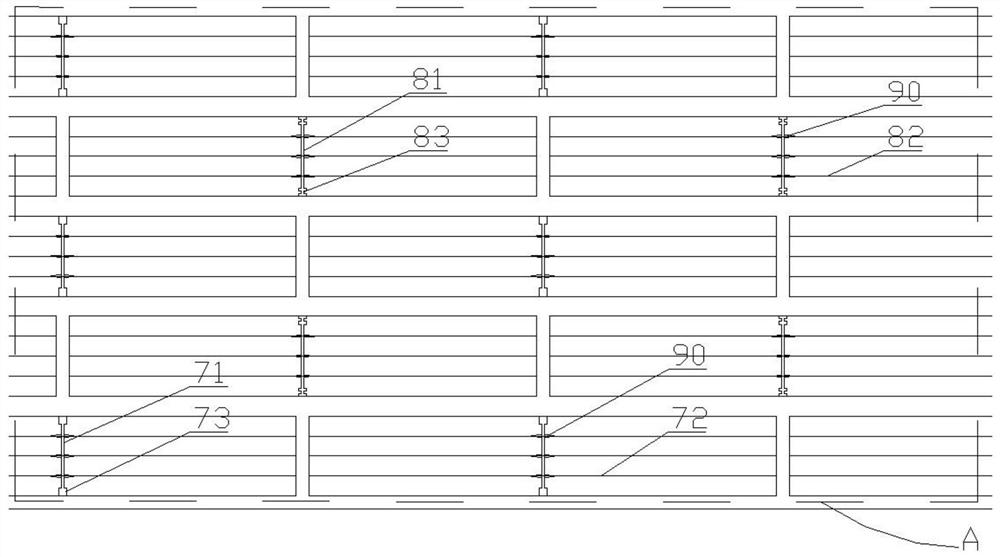

[0046] Such as Figure 1-4 Shown: an IBC solar cell structure with a TOPCon rear passivation contact structure, mainly comprising a crystalline silicon substrate, the front surface of the crystalline silicon substrate 10 includes a front doped layer 11 and a front passivation layer 12 from the inside to the outside, the crystal The back surface of the silicon substrate includes, from the inside to the outside, tunnel oxide layers 20, alternately arranged n+ doped amorphous silicon layers 30, p+ doped amorphous silicon layers 40, laser grooved regions 50, and a back surface passivation layer. 60. Negative electrode 70 / positive electrode 80.

[0047] Wherein, the crystalline silicon substrate 10 is any one of N-type single crystal silicon or P-type single crystal silicon. In this embodiment, the crystalline silicon substrate 10 is N-type single crystal silicon; the front surface of the crystalline silicon substrate 10 is made of Suede with polished back surface.

[0048] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com