Floating crystalline tastant particles

A tastant and particle technology, applied in the field of suspended crystalline tastant particles, can solve the problems of unsolved tastants, sinking and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Coating process method

[0097] Particle coating can be done in different ways. Two different methods suitable for providing suspended particles are described below.

[0098] Fluidized bed coating:

[0099] Crystallized sucrose particles were coated with varying amounts of cocoa butter using fluidized bed techniques. The sucrose granules are fluidized in the treatment chamber and molten cocoa butter (approximately 70° C.) is sprayed on them. After spraying, the powder was continuously fluidized for 10 minutes (20°C-25°C fluidizing air temperature) to solidify the cocoa butter. This method can be used to provide precise amounts of coating.

[0100] High Shear Mixing:

[0101] Crystallized sucrose pellets were coated with varying amounts of fat / oil using a bench top food processor (Kenwood) including a custom made high shear mixer impeller (University of Sheffield). The impeller speed was controlled with a 240V, 7 amp regulator (University of Sheffield). The sucr...

Embodiment 2

[0103] Fluid bed coating of spherical sucrose with cocoa butter

[0104] Spherical sucrose particles (Nonpareil 103) were coated with a small amount of cocoa butter using fluidized bed techniques. The compositions and densities of the samples (SpC1-SpC3) are given in Table 1. Fat content was determined by fat extraction. Pure crystalline sucrose spheres (SpR) were used as reference material. Due to the small amount of cocoa butter applied, the particle density did not change to a great extent.

[0105] Table 1: Composition and Density of Coated Samples

[0106] sample Cocoa butter content [%] Sucrose content [%] Density [g / cm 3 ]

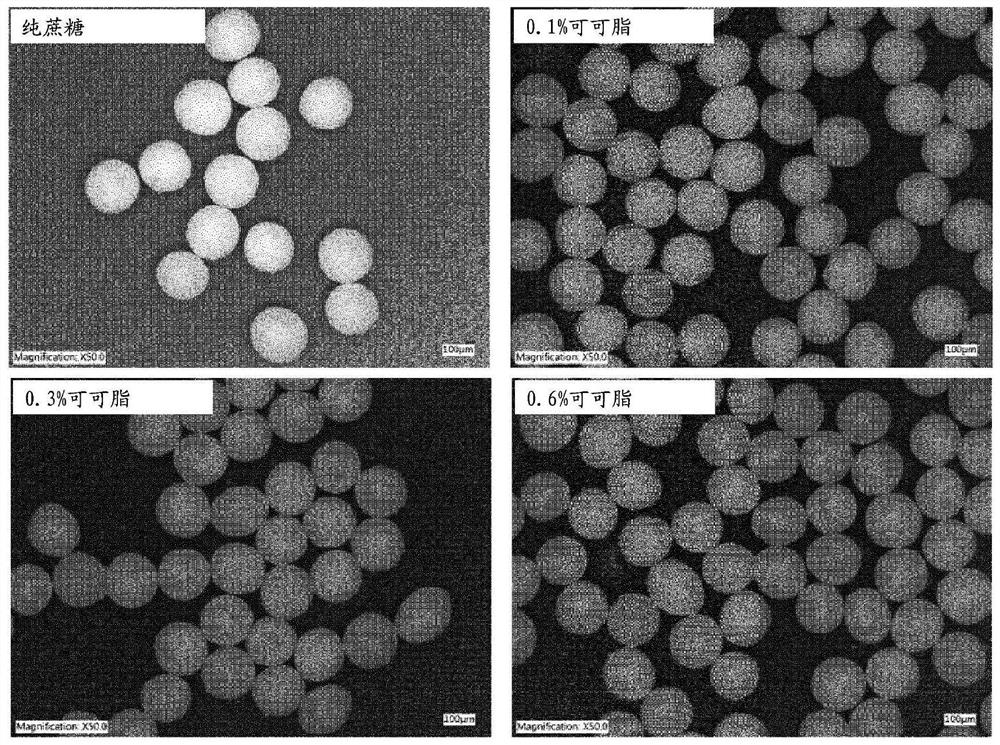

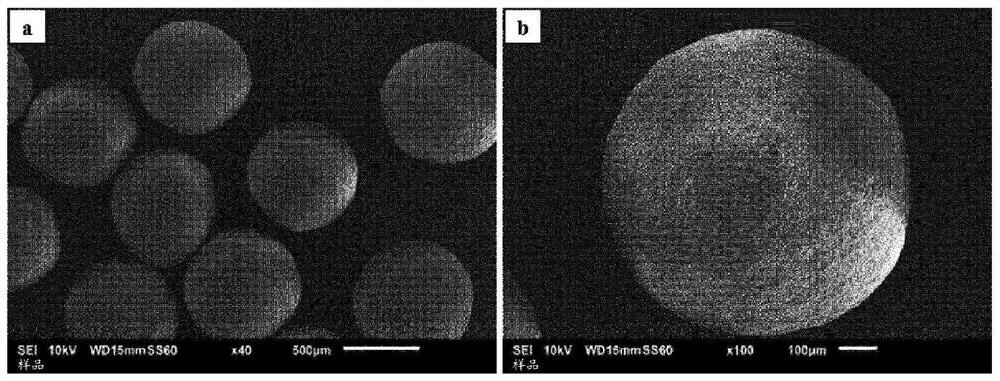

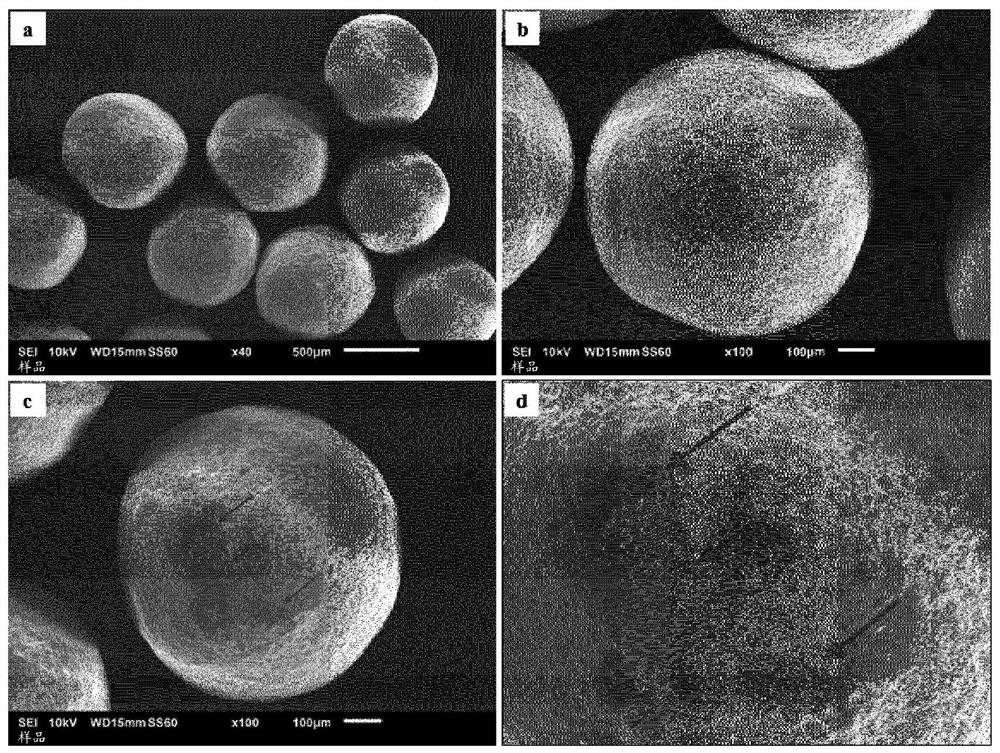

[0107] Such as microscopic images ( figure 1 ), no visible difference was observed between the appearance of the reference sample and the appearance of the coated sample. SEM images of pure and coated particles are shown in Figure 2 to Figure 5 middle. For samples SpC1 and SpC2, the cocoa butter covering the surface is ...

Embodiment 3

[0109] Effect of Cocoa Butter Coating on Wettability

[0110] Apparent contact angles were measured using the sessile drop technique. A layer of coated powder is secured to the adhesive tape and a droplet is placed on the powder layer. For pure sucrose, tablets were compressed (pressure: 20 kN, compaction speed: 10 mm / min) and droplets were positioned on the tablets. Contact angles were measured using a goniometer.

[0111] The measured apparent contact angles are given in Table 2. Particle coating leads to a significant increase in the apparent contact angle. The apparent contact angle increases with the increase of cocoa butter content.

[0112] Table 2: Apparent contact angles of pure spherical sucrose particles and coated spherical sucrose particles

[0113] sample Apparent contact angle [°] pure sucrose 20±5 SpC1 75±5 SpC2 85±5 SpC3 110±4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com