Beef jerky processing equipment and method

A beef and equipment technology, applied in the field of food processing, can solve problems such as loss of competitiveness, low efficiency, and reduced beef flavor, and achieve the effect of reducing manual operations, time and difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

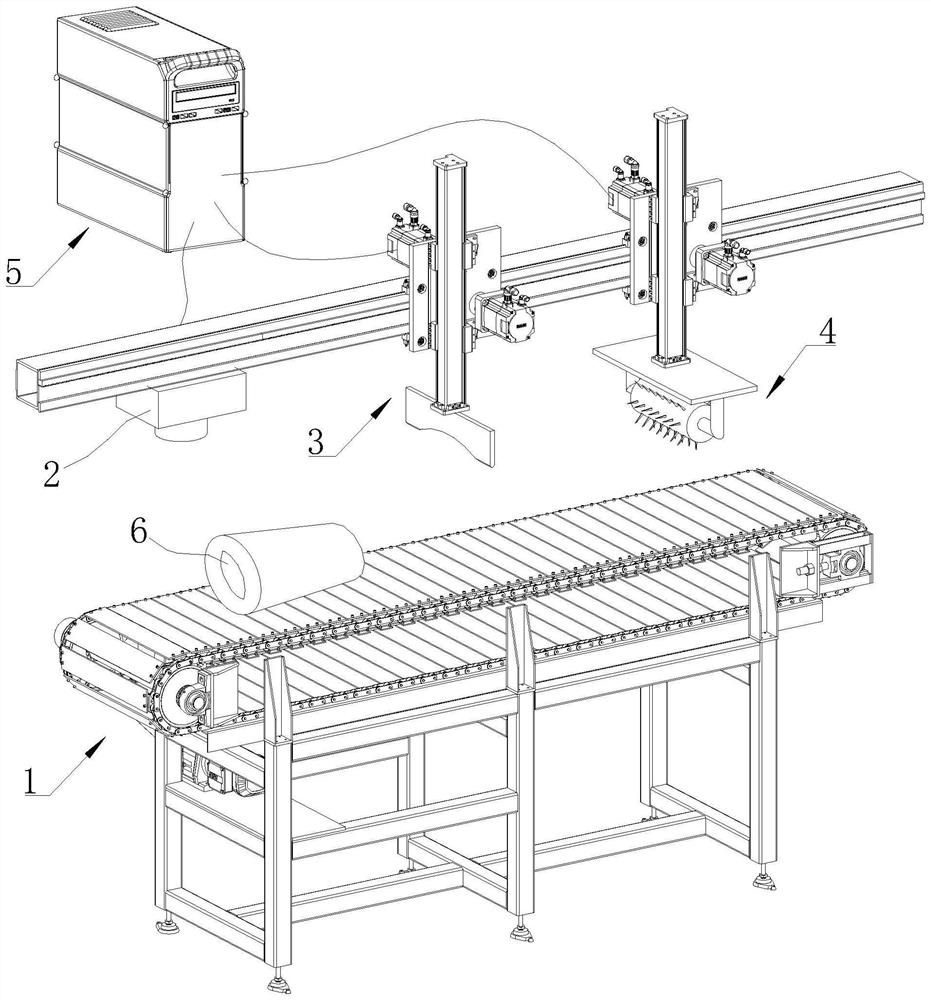

[0053] Specific embodiment one: please refer to Figure 1-4 A beef jerky processing equipment includes a fat removal unit, a blood removal unit, a segmentation unit and a cooking unit.

[0054] The degreasing unit includes a conveyor belt 1 , a fascia camera 2 , a cutting component 3 , a rib removal component 4 , and a controller 5 .

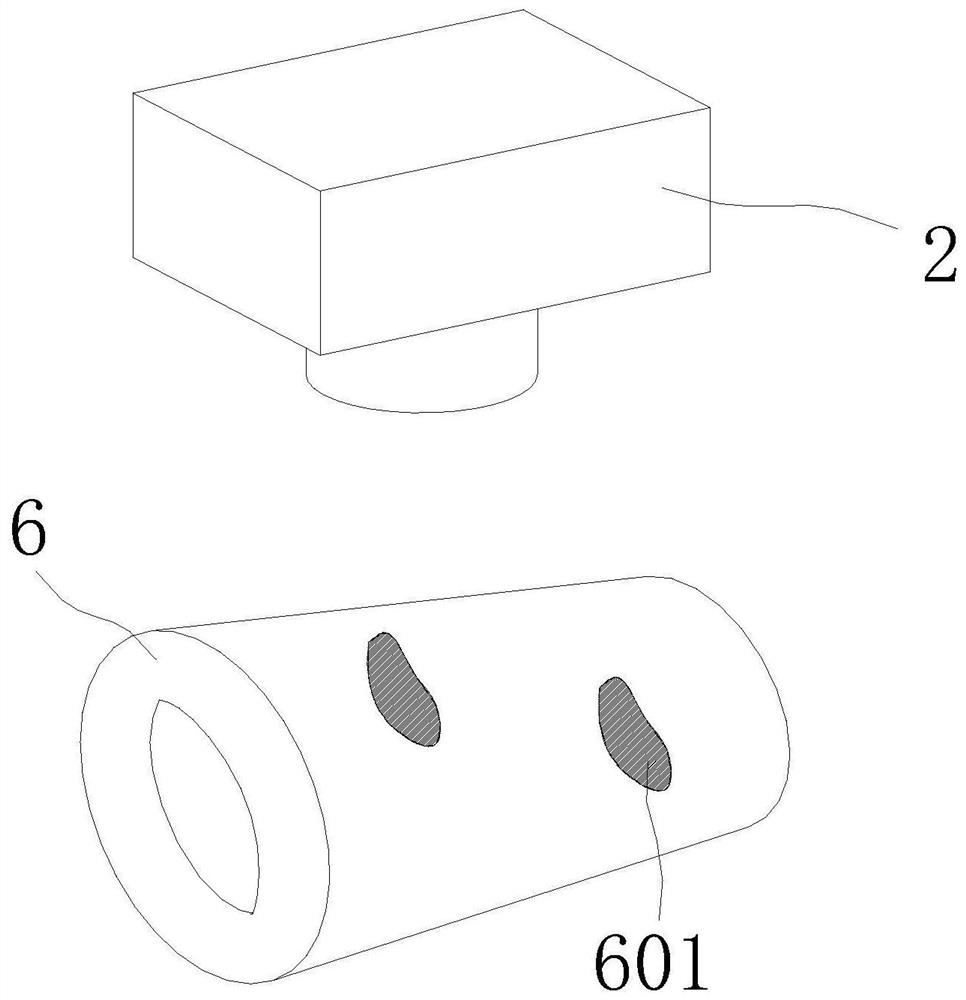

[0055] Conveyor belt 1 is used for supporting and transporting the beef shank 6 that has been peeled to be degreased.

[0056] The upper side of the conveyor belt 1 is fixedly provided with truss wires. The fascia camera 2, the cutting assembly 3 and the rib removal assembly 4 are sequentially arranged on the truss line.

[0057] The fascia camera 2 is used to photograph the surface image of the beef shank 6 on the conveyor belt 1, and transmits the image information to the controller 5. The controller 5 determines the position of the superficial fascia 601 on the beef round 6 according to the image information.

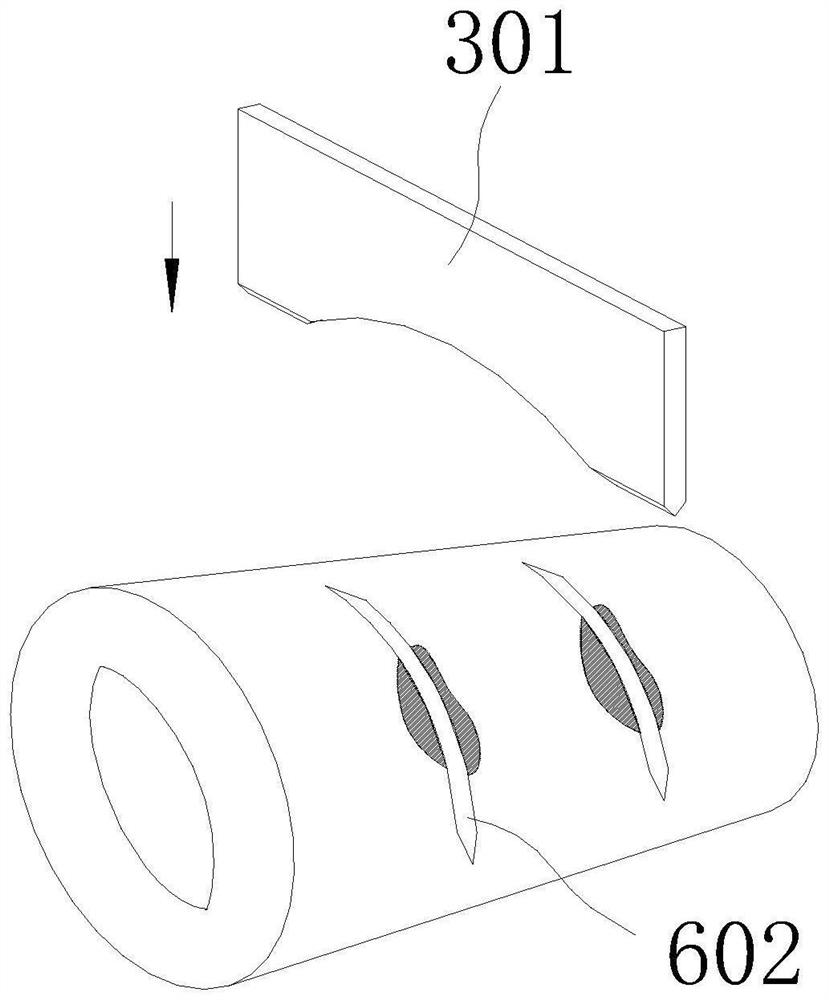

[0058] The cutting assembly...

specific Embodiment 2

[0064] Specific embodiment two: on the basis of specific embodiment one, please refer to Figure 5 A kind of beef jerky processing equipment, the outer periphery of the roller 402 is covered with the adhesion part 404, and the adhesion part 404 is made of flexible material. The needles 403 all pass through the adhesion portion 404 , that is, the adhesion portion 404 covers the part of the outer periphery of the roller 402 that is not covered by the needle 403 .

[0065] The outer side of the adhesion part 404 is covered with dry absorbent paper, which only absorbs water, not oil, so that the moisture in the fascia 601 is absorbed, and only oil molecules are present on the surface of the fascia 601, when the oil molecules come into contact with the dry absorbent paper Adhesion with absorbent paper immediately afterwards increases the probability that the fascia 601 is separated from the beef shank 6 .

specific Embodiment 3

[0066] Specific embodiment three: on the basis of specific embodiment two, please refer to Figure 6 A beef jerky processing equipment, the adhesion part 404 includes an adhesive layer 405 and a waterproof layer 406. The adhesive layer 405 is fixedly connected with the waterproof layer 406 . The adhesive layer 405 is located outside the waterproof layer 406 . The adhesive layer 405 is a contact layer with the sirloin 6 . The adhesive layer 405 is made of dry absorbent paper material. The waterproof layer 406 is made of waterproof and oilproof flexible material. The adhesive part 404 is wrapped around the outer periphery of the roller 402 and has at least one layer. The adhesive layer 405 is located on the outside, and the waterproof layer 406 is located on the inside. The grease of the layer 405 penetrates into the inner adhesive layer 405, causing the two adhesive layers 405 to stick together, and the failure of the secondary adhesive fascia 601 occurs.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap