Device and method for improving dissolution rate of medicine for treating parasitic infection

A dissolution rate and parasite technology, applied in chemical instruments and methods, mixers with rotating stirring devices, dissolution, etc., can solve problems such as mixing, microcrystalline cellulose loss, microcrystalline cellulose composition error, etc., to avoid Loss, improve the effect of drug dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

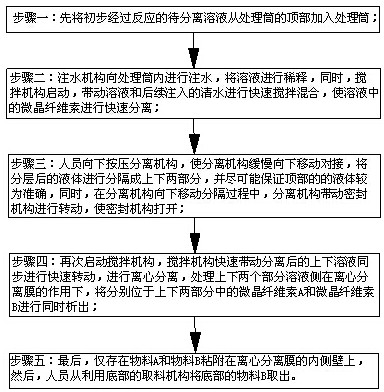

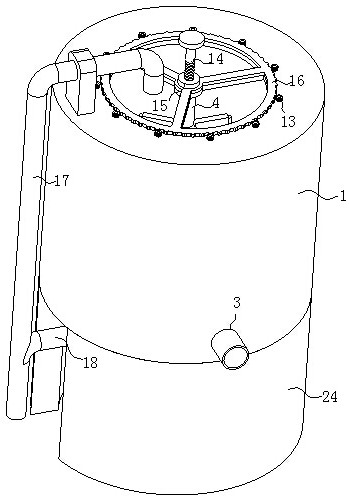

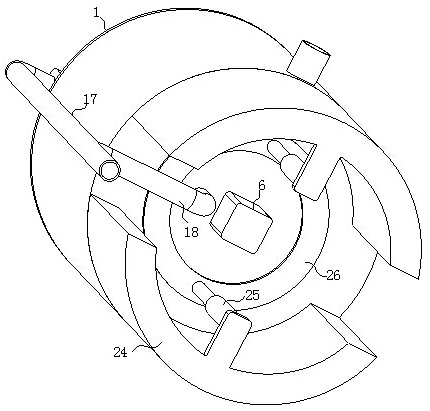

[0039] see Figure 1-10 , the present invention provides a technical solution: a device for improving the dissolution rate of drugs for treating parasitic infections, including a treatment cylinder 1, the inner side of the treatment cylinder 1 is fixedly connected with a centrifugal separation membrane 2, and the inner side of the treatment cylinder 1 is connected with a During the process, the sealing mechanism that supports and seals the centrifugal separation membrane 2 is connected to the inner side of the processing cylinder 1 with a stirring mechanism that is used to stir and mix the inner side of the centrifugal separation membrane 2. Separate separation mechanism, the separation mechanism is opened during the mixing process of microcrystalline cellulose, the separation mechanism drives the sealing mechanism to open while separating the liquid, the side wall of the treatment cylinder 1 is connected with a water injection mechanism for water injection, the left side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com