Energy-saving and environment-friendly device for construction engineering

An energy-saving, environmental-friendly, engineering technology, applied in cleaning methods and appliances, cleaning methods using liquids, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of low cleaning effect of sand and gravel, unfavorable energy saving and environmental protection, and large water consumption. To achieve the effect of increasing the reuse rate, ensuring normal and efficient operation, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

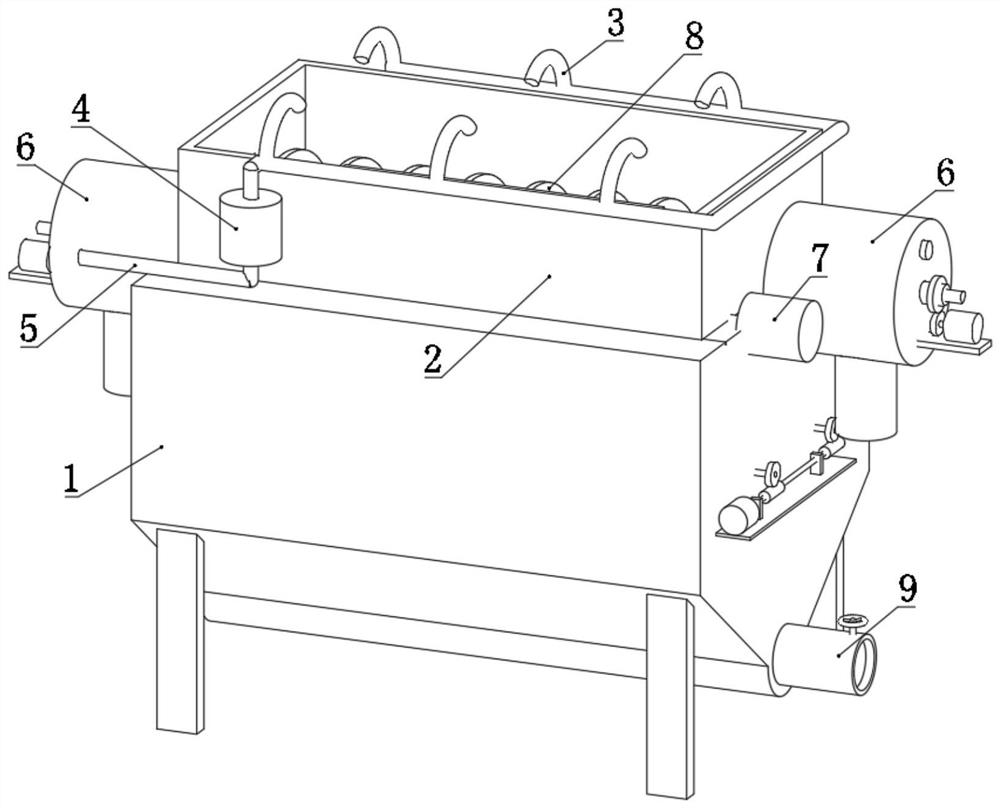

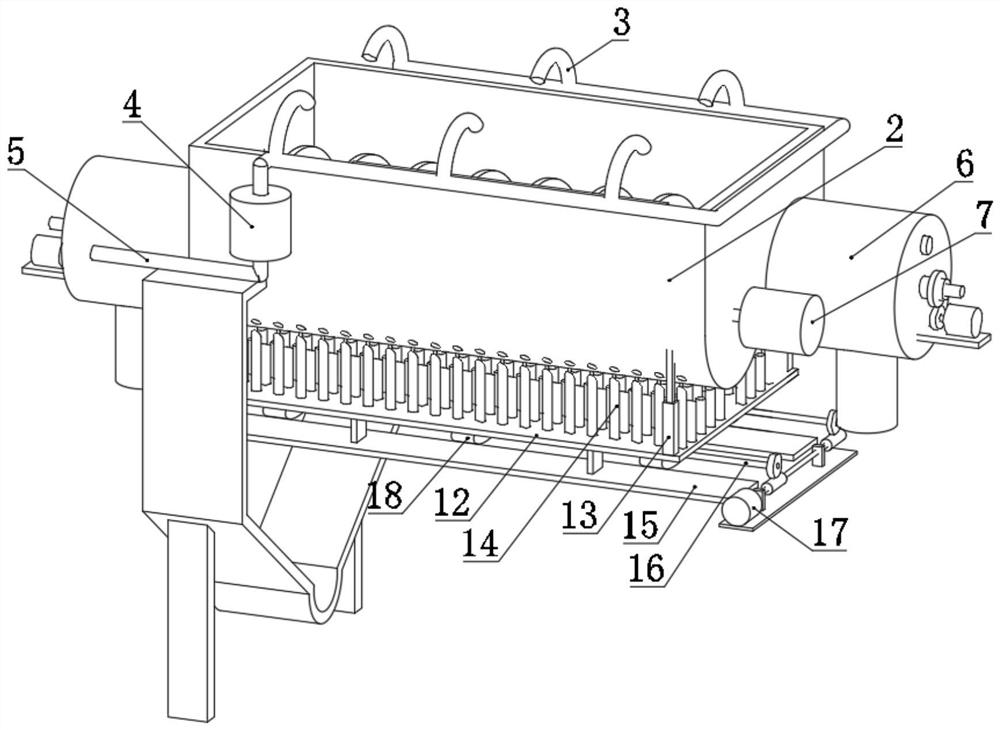

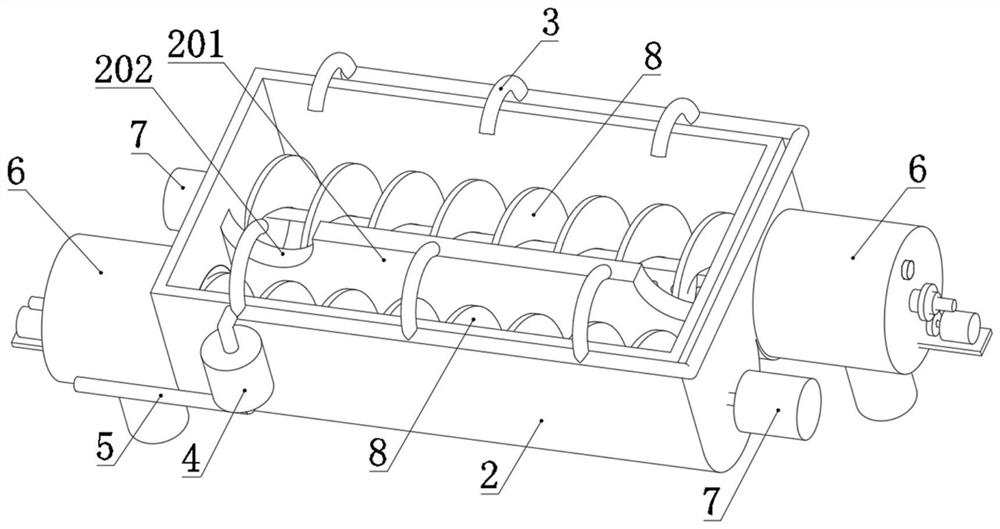

[0046] refer to Figure 1-9 , an energy-saving and environment-friendly construction engineering device, comprising a bottom box body 1, a support column is installed on the bottom outer wall of the bottom box body 1, a sewage pipe 9 is installed on the bottom side of the bottom box body 1, and a valve is installed on the sewage pipe 9 A top box 2 is installed on the top of the bottom box 1, and an outlet pipeline 3 is installed on the top of the top box 2, and the outlet pipeline 3 includes a main pipeline and a plurality of arc-shaped pipelines installed on the upper side of the main pipeline. The water outlet pipeline 3 is installed with the water outlet of the water pump 4, and the water inlet of the water pump 4 is installed with the water inlet pipe 5;

[0047] After the gravel is added to the inside of the top box body 2, the water pump 4 is used to transport the clear water from the water inlet pipe 5 to the water outlet pipe 3, and the clear water can be sprayed into ...

Embodiment 2

[0063] refer to Figure 10-15 , in the second embodiment, the water inlet end of the water pump 4 is also equipped with a recovery pipe 10, the other end of the recovery pipe 10 extends to the inside of the bottom box 1, and the other end of the recovery pipe 10 is equipped with a self-opening and closing recovery mechanism 11 .

[0064] The self-opening and closing recovery mechanism 11 includes a water inlet cover 29 fixed on the bottom end of the recovery pipe 10. The lower side of the water inlet cover 29 is provided with a floating block 30, and the center of the top surface of the water inlet cover 29 is provided with a plug that matches the recovery pipe 10. hole 35, the bottom end of the recovery pipe 10 extends to the inside of the water inlet cover 29 through the jack 35, and there is a gap between the water inlet at the bottom end of the recovery pipe 10 and the inner bottom wall of the water inlet cover 29, and the top of the water inlet cover 29 Two arc-shaped wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com